Electro-hydraulic system for recycling and releasing potential energy of engineering machinery

A technology of gravitational potential energy and engineering machinery, which is applied to fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of low power density, inability to provide energy instantaneously, and high cost of super capacitors or batteries. The effect of improving efficiency, low price, and reducing the link of energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

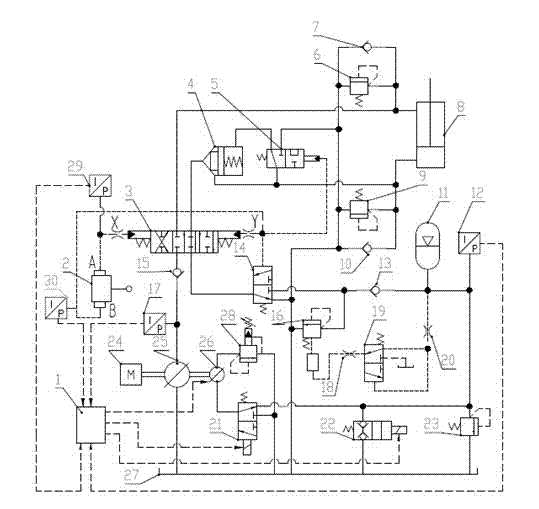

[0031] In order to improve the safety of the electro-hydraulic system of the present invention and reduce energy loss, as a preferred embodiment of the present invention, the reversing mechanism may further include a hydraulically controlled one-way valve 4 and a second hydraulically controlled two-position three-way valve 5 . Such as figure 1 As shown, port B of the hydraulically controlled one-way valve 4, port P of the second hydraulically controlled two-position three-way valve 5, and the rodless chamber of the lifting hydraulic cylinder 8 communicate with each other, and port A of the hydraulically controlled one-way valve 4 is connected to the multi-way The B port of the valve 3 is connected, the A port of the second hydraulically controlled two-position three-way valve 5 is connected with the spring cavity of the hydraulic control check valve 4, and the B port of the second hydraulically controlled two-position three-way valve 5 is connected with the oil tank 27.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com