Method for researching microbial degradation of petroleum pollutants under low-temperature high-salt conditions

A technology of pollutants and petroleum, applied in the direction of biochemical equipment and methods, microorganism measurement/inspection, etc., can solve the problems of unstable microbial film structure and affecting microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

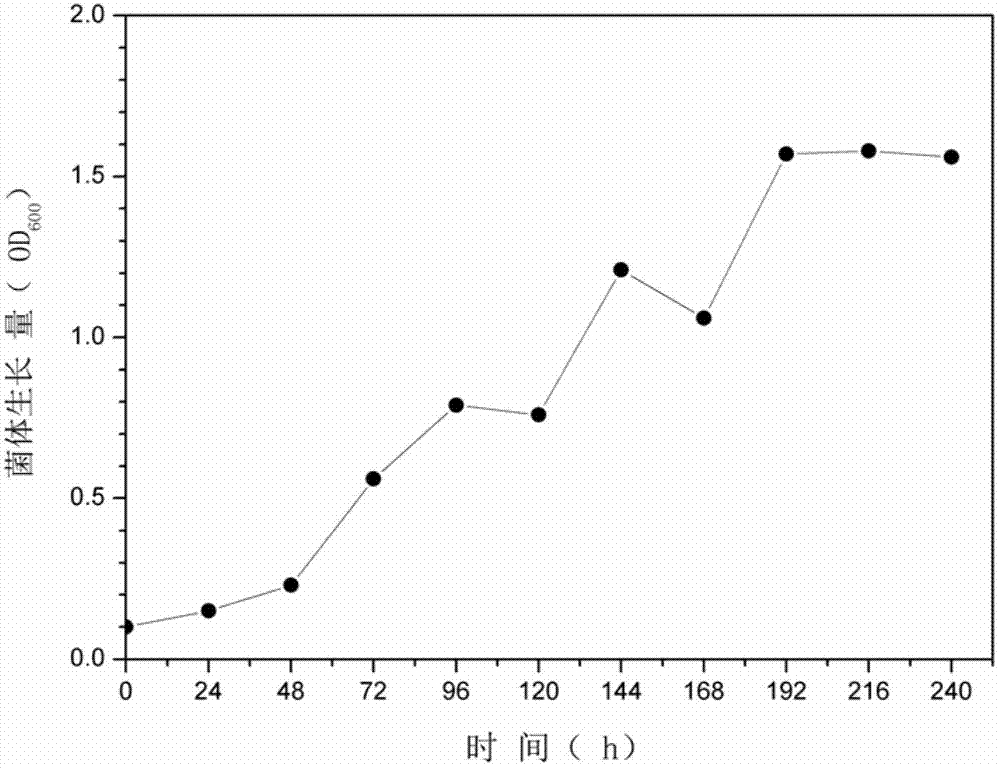

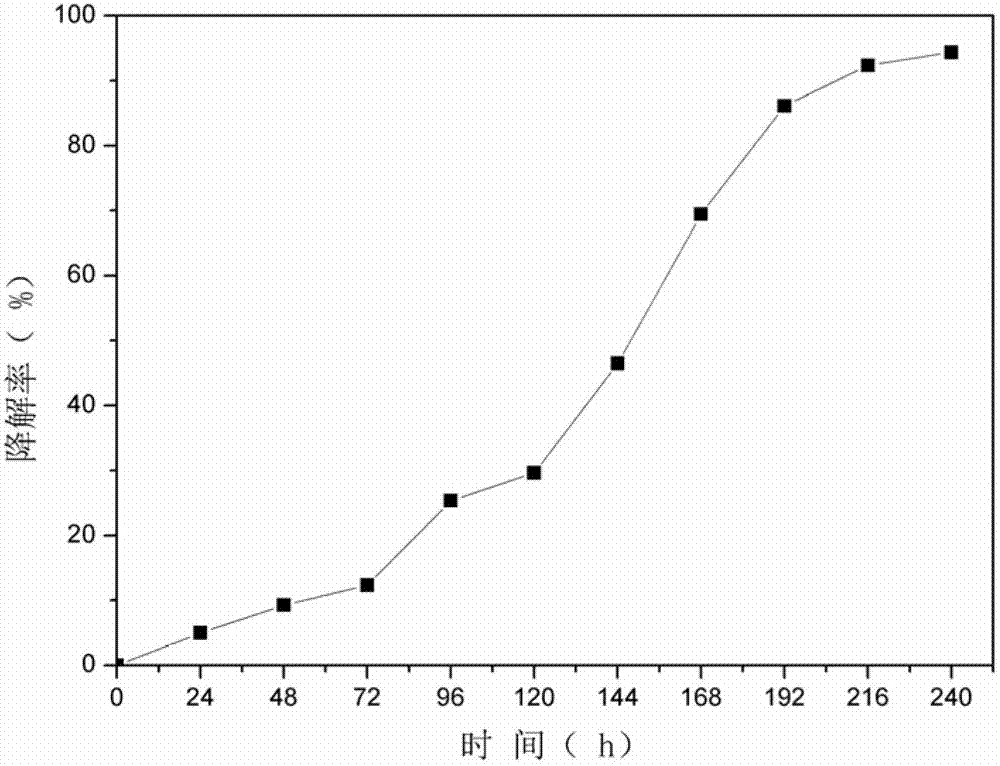

Embodiment 1

[0024] Configure inorganic salt medium, sodium nitrate 0.5g / L, potassium dihydrogen phosphate 0.5g / L, potassium dihydrogen phosphate 0.5g / L, ammonium sulfate 4g / L, NaCl20g / L, magnesium sulfate 2g / L. Add trace elements 5mL / L to adjust the pH to 6.5. Divide 100mL of inorganic salt medium into 250mL Erlenmeyer flasks, seal and sterilize at 121°C for 20 minutes, cool to room temperature, add initial OD 600 0.1 for mycobacterial cp1. Add petroleum hydrocarbons that have been sterilized and passed through a 0.22 micron oil film in the inoculated inorganic salt medium. Placed in a shaker at 5°C and 180rpm for 10 days, the remaining petroleum hydrocarbons were extracted with n-hexane, and the degradation rate of petroleum hydrocarbons was 56.37% by comparing the changes in petroleum hydrocarbon content before and after.

Embodiment 2

[0026] Prepare inorganic salt medium, sodium nitrate 1g / L, potassium dihydrogen phosphate 1g / L, potassium dihydrogen phosphate 1g / L, ammonium sulfate 2g / L, NaCl 30g / L, magnesium sulfate 0.5g / L. Add 10mL / L of trace elements to adjust the pH to 6.5. Divide 100mL of inorganic salt medium into 250mL Erlenmeyer flasks, seal and sterilize at 121°C for 20 minutes, cool to room temperature, add initial OD 6000.1 for mycobacterial cp1. Add petroleum hydrocarbons that have been sterilized and passed through a 0.22 micron oil film in the inoculated inorganic salt medium. Placed in a shaker at 10°C and 200rpm for 12 days, the remaining petroleum hydrocarbons were extracted with n-hexane, and the degradation rate of petroleum hydrocarbons was 87.90% by comparing the changes in petroleum hydrocarbon content before and after.

Embodiment 3

[0028] Prepare inorganic salt medium, sodium nitrate 2g / L, potassium dihydrogen phosphate 1.5g / L, potassium dihydrogen phosphate 1.5g / L, ammonium sulfate 3g / L, NaCl 50g / L, magnesium sulfate 1.5g / L. Add 15mL / L of trace elements to adjust the pH to 7.5. Divide 100mL of inorganic salt medium into 250mL Erlenmeyer flasks, seal and sterilize at 121°C for 20 minutes, cool to room temperature, add initial OD 600 0.1 for mycobacterial cp1. Add petroleum hydrocarbons that have been sterilized and passed through a 0.22 micron oil film in the inoculated inorganic salt medium. Placed in a shaker at 15°C and 250rpm for 16 days, the remaining petroleum hydrocarbons were extracted with n-hexane, and the degradation rate of petroleum hydrocarbons was 63.49% by comparing the changes in petroleum hydrocarbon content before and after.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com