Overall composite inner high-pressure flow type bulging device for car drive axle

A drive axle and internal high pressure technology, applied in fluid pressure actuators, vehicle components, transportation and packaging, etc., can solve the problems of difficult control of bulging force, fatigue fracture of welding area, easy cracks and pores, etc., to meet the requirements of Use requirements, reduce space, improve the effect of hydraulic pressure stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

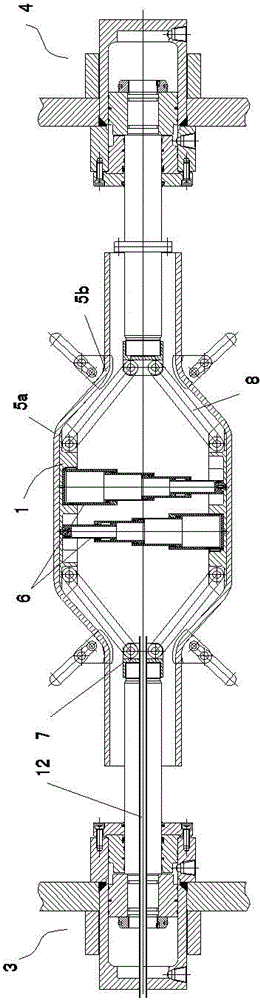

[0060] Such as figure 1 As shown, it is a structural schematic diagram of the first embodiment of the integrated high-pressure flow type bulging device of the automobile drive axle after the bulging deformation of the workpiece is completed.

[0061] The overall composite internal high-pressure flow type bulging device of the automobile drive axle in this embodiment includes a bulging inner mold 1, a bulging outer mold 2, and thrust hydraulic cylinders located at both ends of the bulging inner mold 1 and used to provide auxiliary mold clamping force 3 and thrust hydraulic cylinder 4.

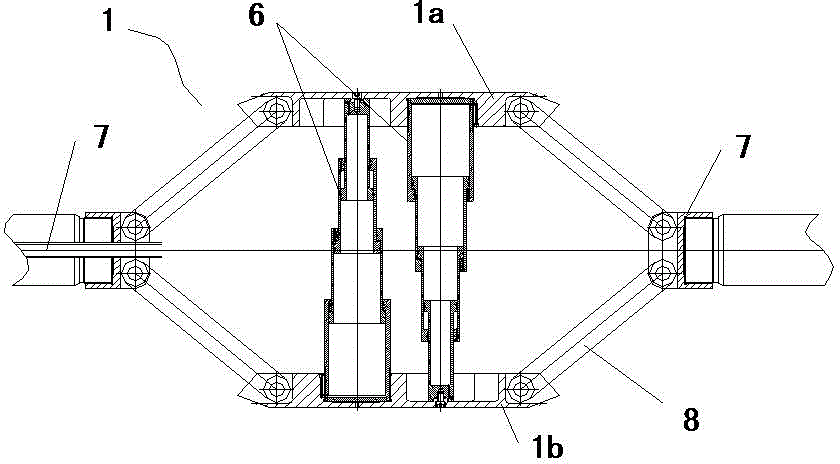

[0062] Such as image 3 As shown, the bulging inner mold 1 includes an upper module 1a and a lower module 1b respectively matched with the upper and lower inner walls of the axle housing pipa bag 5a, and at least one module acting on the upper module 1a and the lower module 1b is arranged between the upper module 1a and the lower module 1b. On the module 1b, there is a multi-stage high-pressur...

no. 2 example

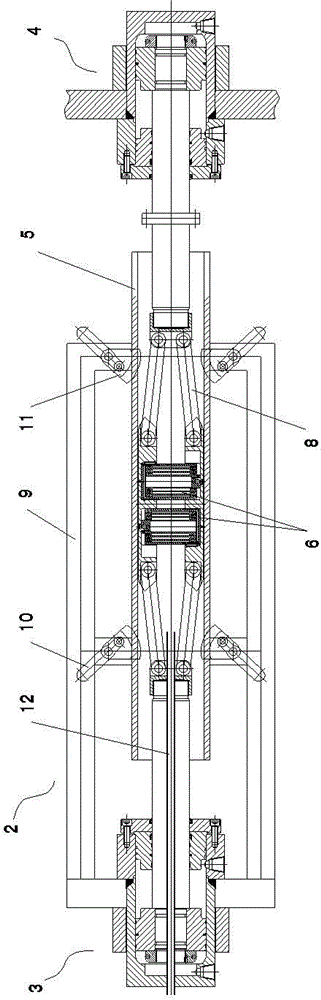

[0075] Such as Figure 5 As shown, it is a structural schematic diagram of the second embodiment of the integral composite internal high-pressure flow type bulging device of the automobile drive axle of the present invention after the bulging deformation of the workpiece is completed; Figure 6 It is a structural schematic diagram of the integrated high-pressure flow type bulging device of the automobile drive axle in this embodiment before the workpiece is bulging and deformed.

[0076] The bulging outer mold 2 of the present embodiment comprises an upper outer mold 13 and a lower outer mold 14, and the upper outer mold 13 and the lower outer mold 14 are respectively provided with upper mold cavities with the same shape and structure as the outer walls of the upper and lower sides of the axle housing pipa bag 5a 13a and the lower mold cavity 14a, the support mechanism is the upper mold cavity support inner wall 13b and the lower mold cavity support inner wall 14b correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com