Cyclone separation device

The technology of a cyclone separation device and a cyclone cylinder is applied in the direction of a cyclone device, a device whose axial direction of the cyclone can be reversed, etc. It can improve the separation efficiency, reduce the influence of the swirling flow velocity, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

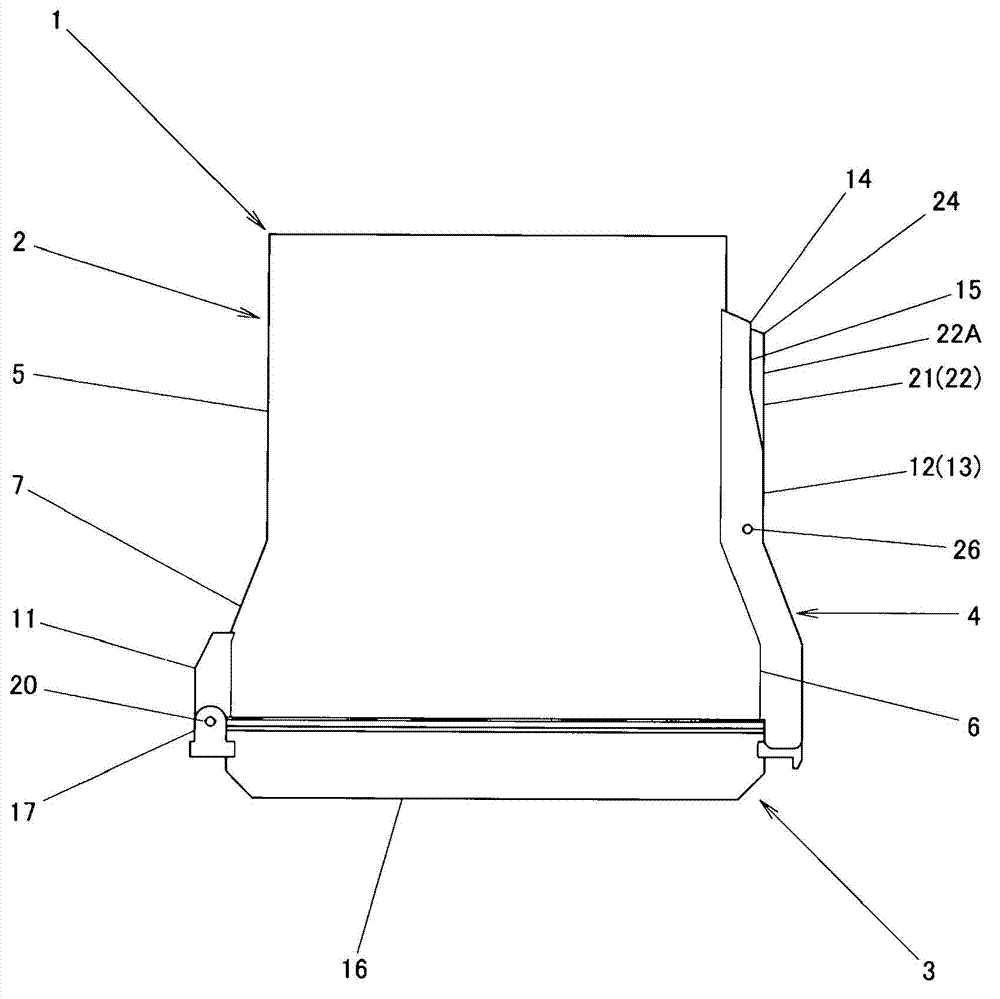

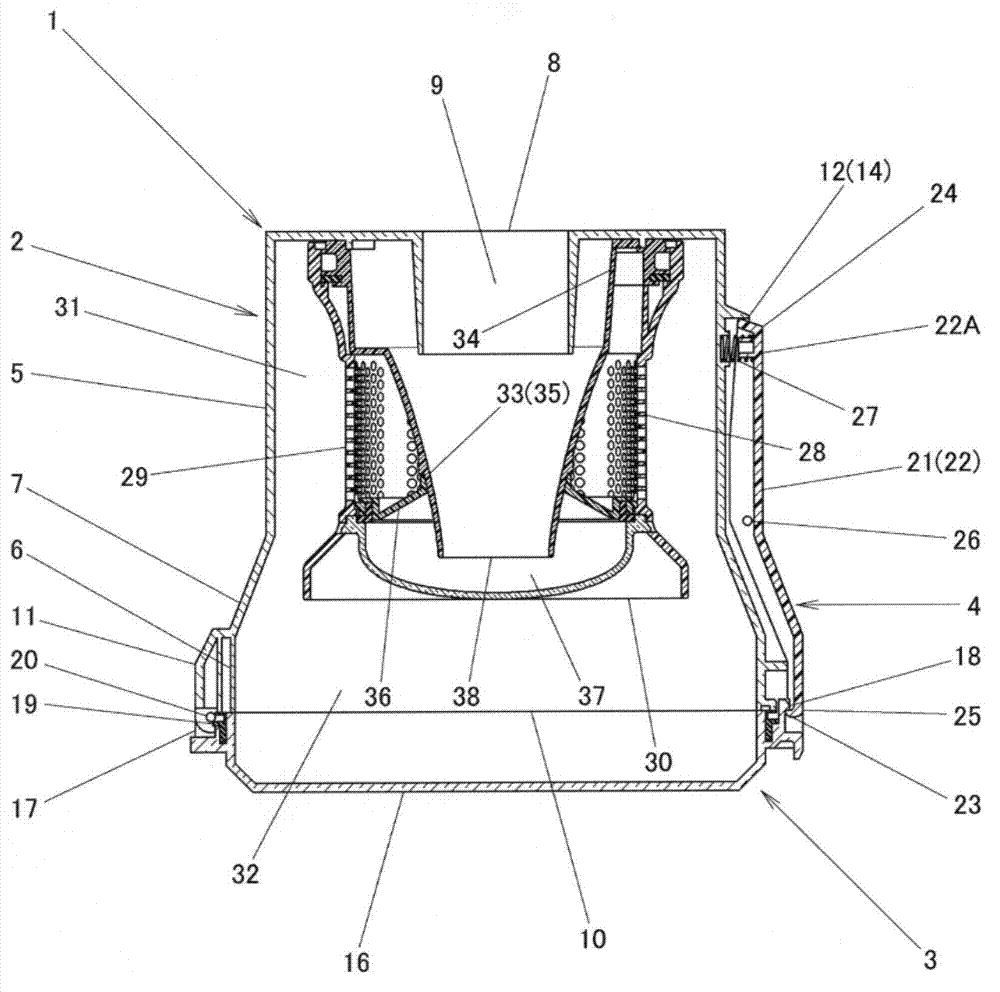

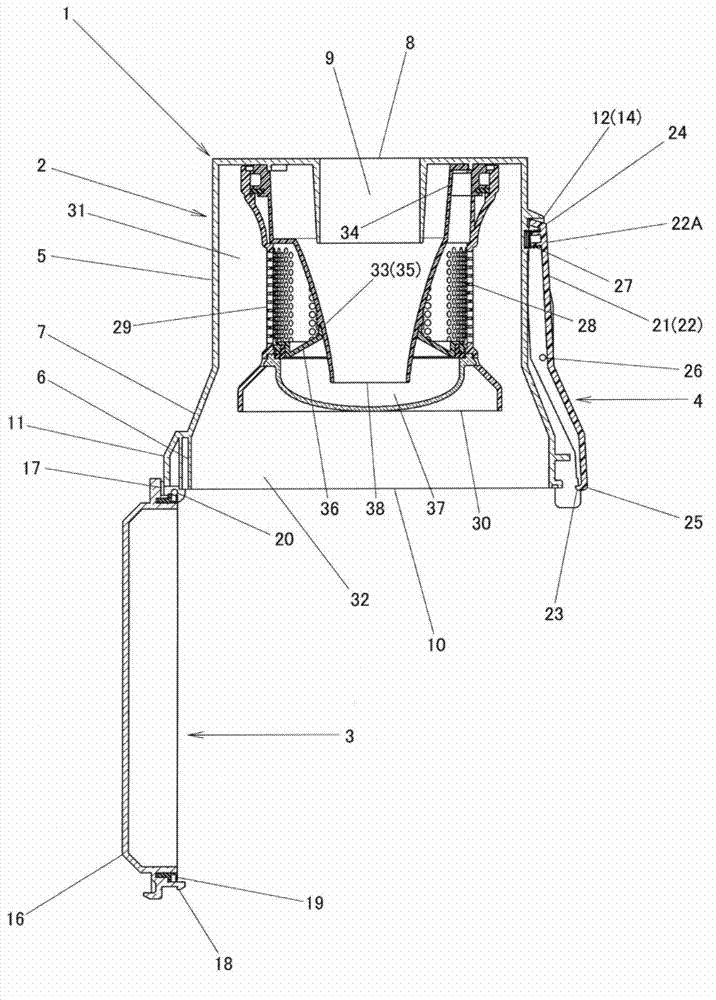

[0016] Below, according to Figure 1 to Figure 4 Embodiments of the present invention will be described. Also, in the following description, the Figure 1 to Figure 4 Up and down in is specified as up and down. and, will Figure 1 to Figure 4 The left in the middle is defined as the front, and the right is defined as the rear. Reference numeral 1 denotes a cyclone dust collector as a cyclone separation device of the present invention. The cyclone dust collector 1 has a cyclone 2 , a bottom cover 3 , and an engaging mechanism 4 .

[0017] The cyclone 2 is formed of transparent synthetic resin. Furthermore, the cyclone 2 has a small-diameter portion 5 with a relatively small diameter, a large-diameter portion 6 with a relatively large diameter, and an intermediate portion 7 whose diameter gradually changes so as to connect the small-diameter portion 5 and the large-diameter portion 6 . An exhaust port 8 connected to an electric blower (not shown) is formed at the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com