Energy-saving frequency converter of induction motor direct torque control speed regulating system and structured approach

A direct torque control, energy-saving inverter technology, applied in the estimation/correction of motor parameters, etc., can solve the problem of not being able to balance high performance and high efficiency, and achieve low cost, reduced power loss, and fast dynamic response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

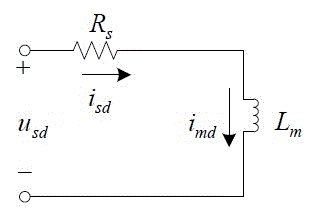

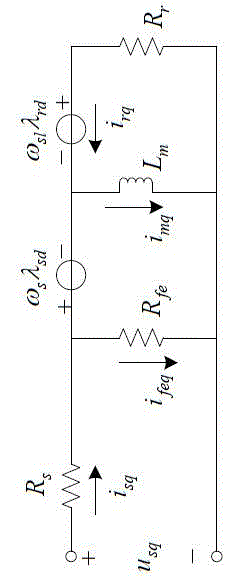

[0034] With reference to the accompanying drawings, according to the approximate equivalent circuit model of the induction motor in the stator field-oriented coordinate system (such as figure 1 ), can derive the total loss of the motor under certain working conditions

[0035]

[0036] in , , ;

[0037] make , the condition that the power loss is extremely small can be obtained as

[0038]

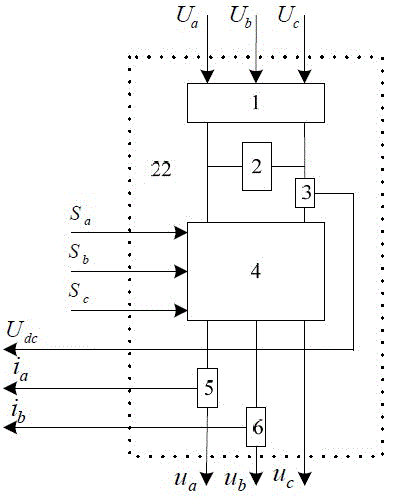

[0039] Based on this, the optimal stator flux calculation module 23 is constructed, and the optimal stator flux calculation module is placed in the direct torque control system to form an induction motor energy-saving frequency conversion controller 24, an induction motor energy-saving frequency conversion controller 24 and a power converter. 22 together form an induction motor energy-saving frequency converter 25, wherein the switch logic table 13 in the induction motor energy-saving frequency conversion controller 24 outputs the control inverter switch signal ( ) conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com