Preparation method and application of carbon-coated grapheme-based metal oxide composite

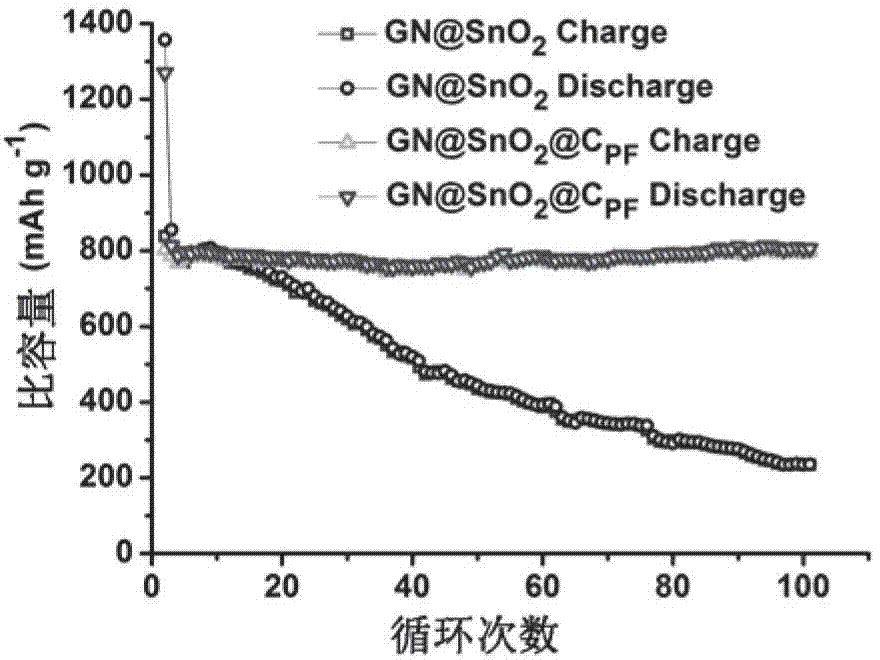

A composite material and graphene technology, which is applied in the fields of materials science and electrochemistry, can solve the problems of rapid capacity decay, low graphite cost, and electrode pulverization, and achieve excellent cycle stability and rate performance, simple process, and mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The first step, preparation of graphene-based tin dioxide nanosheets:

[0047] (1) Add 20% polydiene dimethyl ammonium chloride aqueous solution (0.5mL) to the aqueous solution (60mL) of 0.2mg / mL graphene oxide, and ultrasonically form a uniformly mixed dispersion;

[0048] Wherein, the mass usage ratio of graphene oxide and polydiene dimethyl ammonium chloride in the dispersion liquid is 1:8.

[0049] (2) Add hydrochloric acid to the above dispersion to adjust the pH of the solution to 2; add stannous chloride (SnCl 2 2H 2 0), adding and insulated at 90°C for one hour, cooling;

[0050] Among them, the added SnCl 2 2H 2 The mass ratio of O to graphene oxide is 30:1.

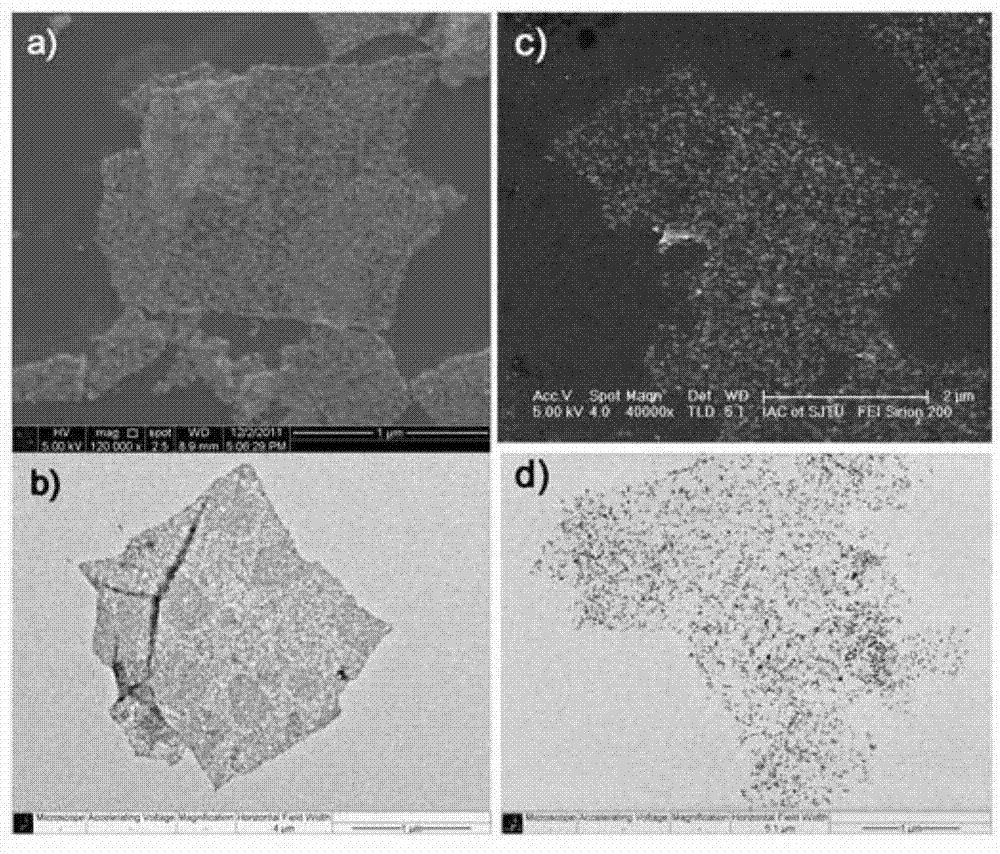

[0051] (3) The solution after the above reaction is centrifuged, washed with deionized water, repeated centrifugal and washing operations three times to obtain a black solid, which is a graphene-based tin dioxide nanosheet, the graphene-based tin dioxide nanosheet SEM and TEM photos are as follows ...

Embodiment 2

[0059] The first step, preparation of graphene-based iron oxide nanosheets

[0060] (1) Add 20% polydiene dimethyl ammonium chloride aqueous solution (5 mL) to the aqueous solution (60 mL) of 1 mg / mL graphene oxide, and ultrasonically form a uniformly mixed dispersion;

[0061] Wherein, the mass usage ratio of added graphene oxide and polydiene dimethyl ammonium chloride is 1:16.

[0062] (2) Add ferrous chloride (FeCl 2 4H 2 0), add and be incubated at 90 ℃ for 5 hours, cooling;

[0063] Among them, the added FeCl 2 4H 2 The mass ratio of O to graphene oxide is 15:1.

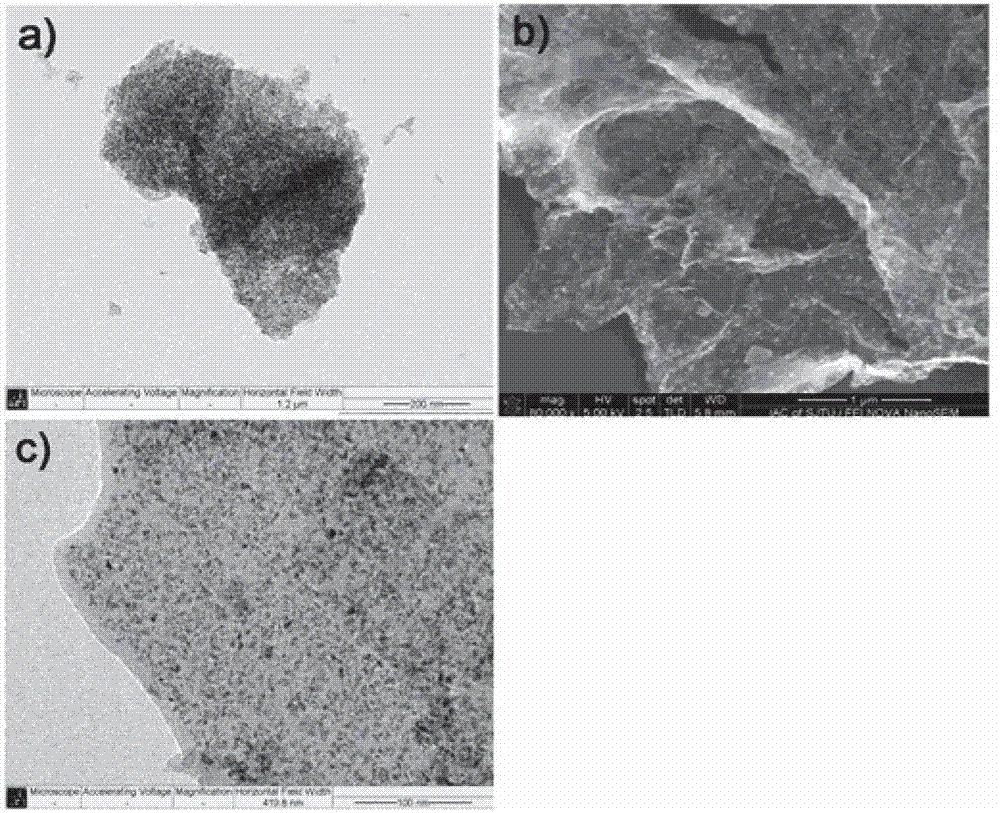

[0064] (3) The solution after the above reaction is centrifuged, washed with deionized water, and the centrifugation and washing operations are repeated three times to obtain a black solid, which is a graphene-based basic iron oxide nanosheet, and the graphene-based basic iron oxide nanosheet The SEM and TEM photos of the film are as follows figure 1 c, 1d shown. The obtained solid was dispersed in deio...

Embodiment 3

[0071] The first step, preparation of graphene-based tin dioxide nanosheets:

[0072] (1) Add 20% polydiene dimethyl ammonium chloride aqueous solution (1.25mL) to the aqueous solution (60mL) of 0.5mg / mL graphene oxide, and sonicate to form a uniformly mixed dispersion;

[0073] Wherein, the mass dosage ratio of added graphene oxide and polydiene dimethyl ammonium chloride is: 1:8.

[0074] (2) Add hydrochloric acid to the above dispersion to adjust the pH of the solution to 2; add stannous chloride (SnCl 2 2H 2 0), adding and insulated at 90°C for one hour, cooling;

[0075] Among them, the added SnCl 2 2H 2 The mass ratio of O to graphene oxide is 30:1.

[0076] (3) The solution after the above reaction is centrifuged, washed with deionized water, and the centrifugation and washing operations are repeated three times to obtain a black solid, which is graphene-based tin dioxide nanosheets. The obtained solid was dispersed in deionized water for use at a concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com