Active organic light emitting diode (OLED)

An active, current technology, applied in the field of electronics, can solve the problems of multiple areas and affect the brightness of OLEDs, and achieve the effects of simple preparation methods, reducing opaque areas, and improving the brightness of OLEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

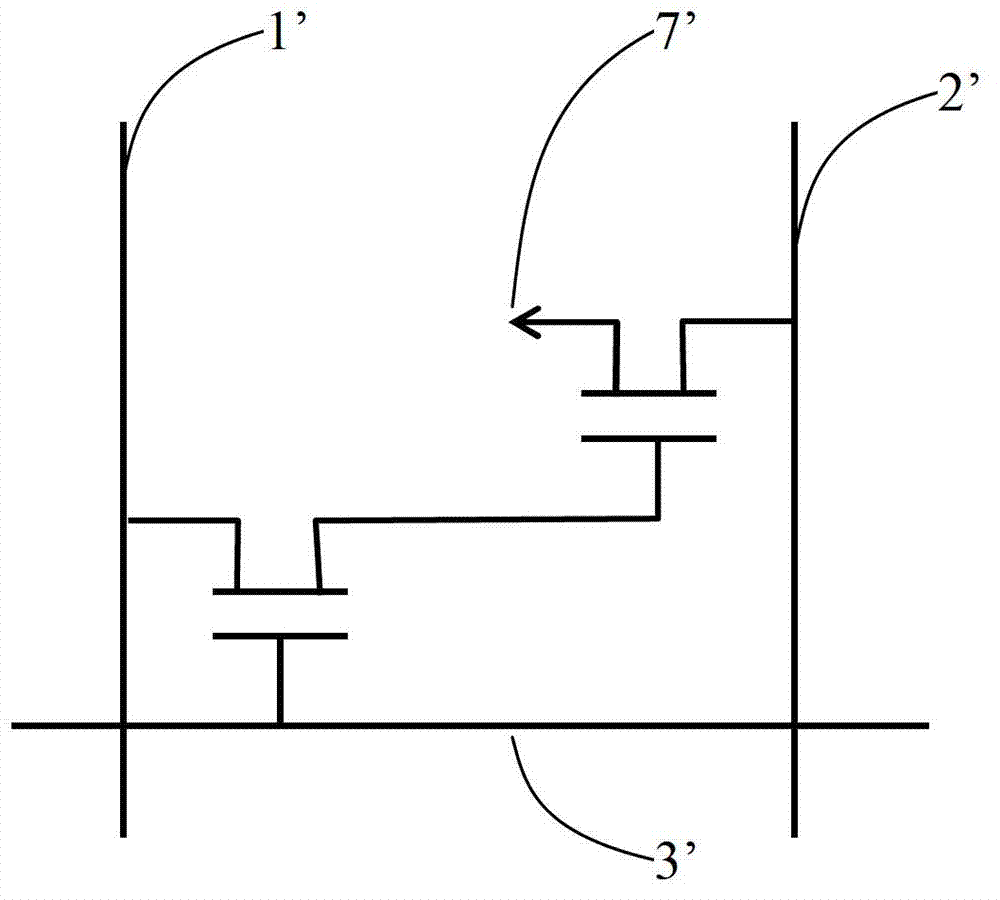

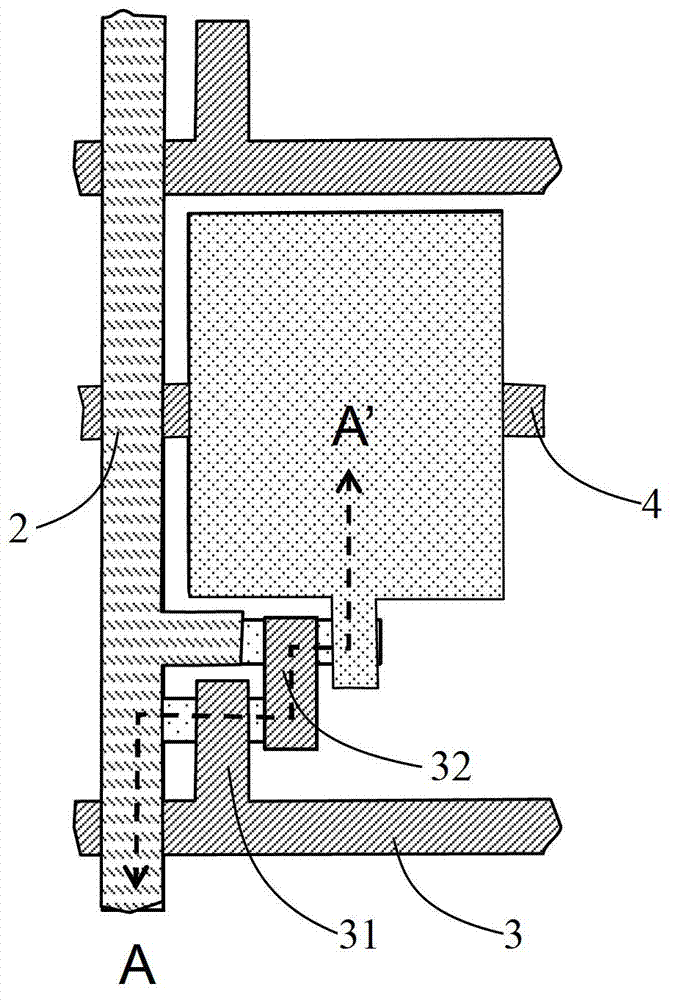

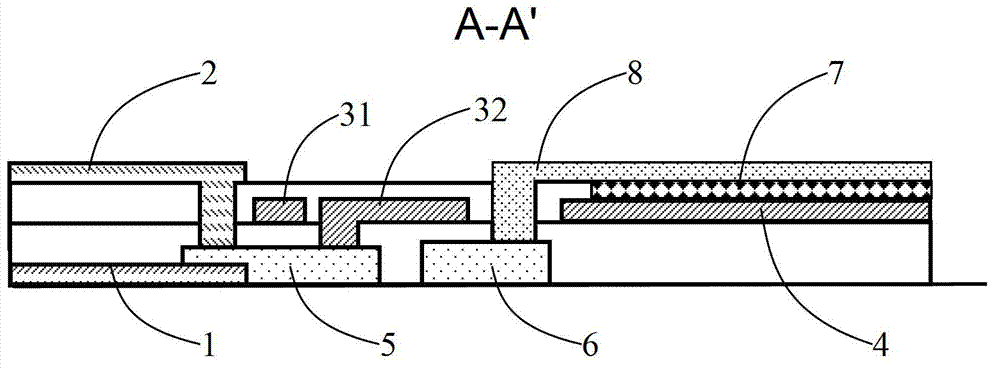

[0052] see figure 2 and image 3 As shown, the common electrode 4 and the scanning line 3 have the same layer structure.

[0053] The specific manufacturing steps are:

[0054] a. Please refer to Image 6 and Figure 7 As shown, the data line 1, the data TFT5 and the current TFT6 are first formed in sequence, and then the first insulating layer is formed, and the first contact hole 51 contacting the data TFT5 is opened on the first insulating layer; wherein, the current TFT5 and the data TFT6 The material is IGZO. IGZO (indium gallium zinc oxide) is the abbreviation of indium gallium zinc oxide. The amorphous IGZO material is the channel layer material used in the new generation of thin film transistor technology.

[0055] Wherein, the data TFT5 and the current TFT6 are located on the same side of the data line 1, the data TFT5 is connected to the data line 1, and the current TFT6 is separated from the data line 1; the current TFT6 is located on one side of the data TFT5...

Embodiment 2

[0060] see Figure 4 and Figure 5 As shown, the common electrode 4 and the data line 1 have the same layer structure.

[0061] The specific manufacturing steps are:

[0062] a. Please refer to Figure 14 and Figure 15 As shown, the data line 1, the common electrode 4, the current TFT6 and the data TFT5 are first formed in sequence, and then the first insulating layer is formed, and the data line 1, the two ends of the current TFT6 and the data TFT5 are opened on the first insulating layer. A contact hole with two ends in contact; wherein, the material of the current TFT6 and the data TFT5 is IGZO. IGZO (indium gallium zinc oxide) is the abbreviation of indium gallium zinc oxide. The amorphous IGZO material is the channel layer material used in the new generation of thin film transistor technology. Wherein, the current TFT6, the data TFT5 and the common electrode 4 are located on the same side of the data line 1 and are separated from the data line 1, wherein the data TF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com