Combined display module and manufacture method thereof

A technology for display modules and manufacturing methods, applied in optics, instruments, electrical digital data processing, etc., can solve problems such as inability to close and easy dust ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention provides a combined display module and a manufacturing method thereof. In a preferred embodiment, the combined display module of the present invention is a liquid crystal display device, and preferably has touch control or stereoscopic display functions. However, in different embodiments, the combined display module can also be a plasma display device, an OLED display device, an electrophoretic display device or the like.

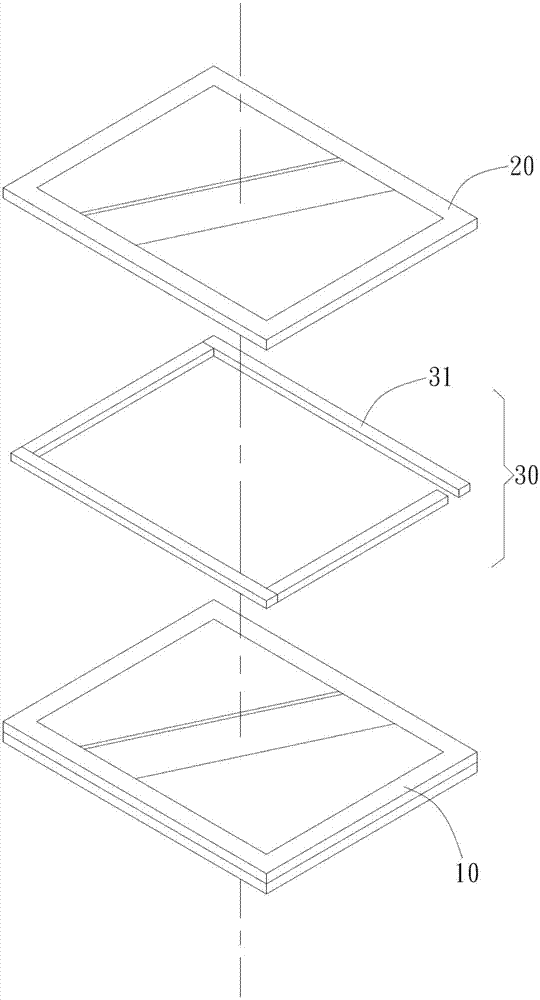

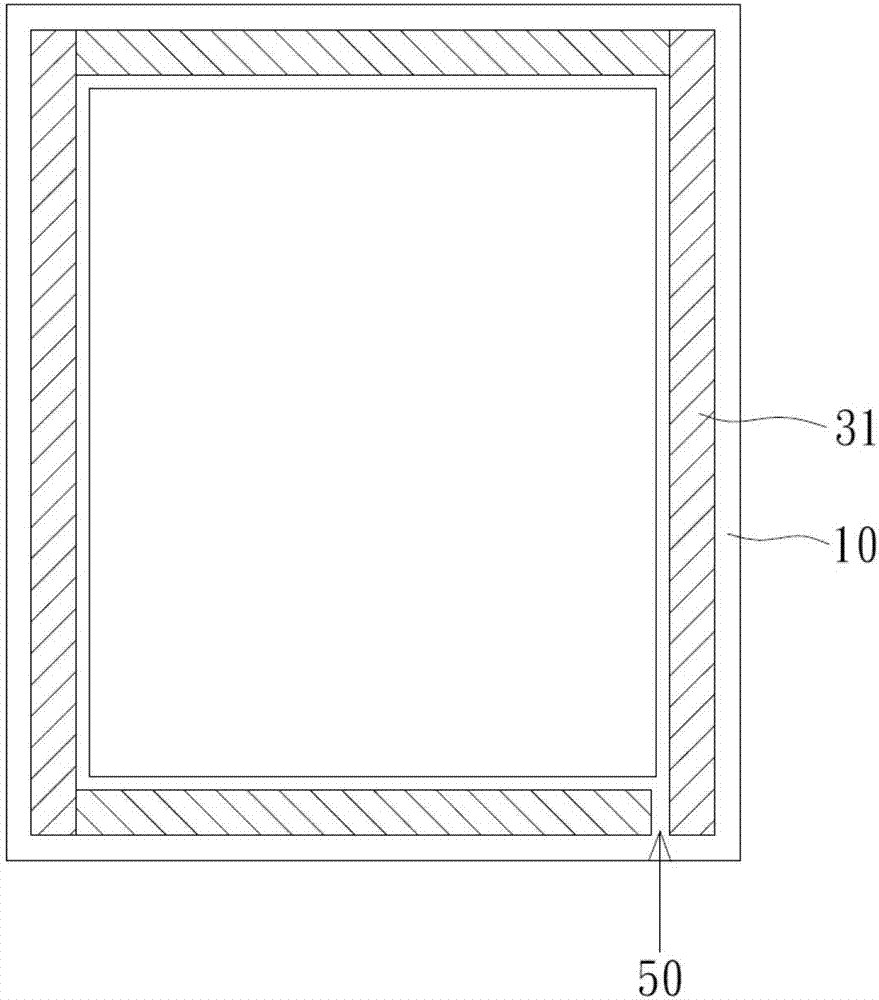

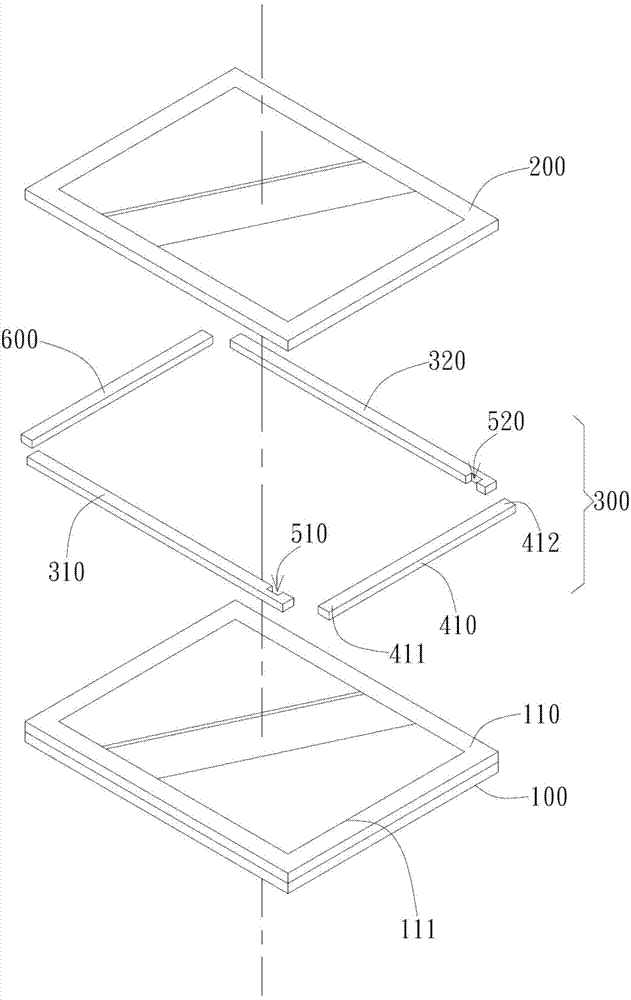

[0053] Such as figure 2 As shown, the combined display module includes a first panel 100 , a second panel 200 and a sealant set 300 . In this embodiment, the first panel 100 is a liquid crystal display panel, but it can also be other different planar, non-planar or flexible display panels. The first panel 100 preferably has a display surface 110, and the display surface 110 has a display area 111, which is an image display area. The part of the display surface 110 outside the display area 111 is preferably surrounded by the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com