Electromagnetic ultrasonic detection probe

An electromagnetic ultrasonic and detection probe technology, which is used in measurement devices, materials analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. It can solve the problems of large probe volume and complex echo analysis, and achieve the effect of high receiving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

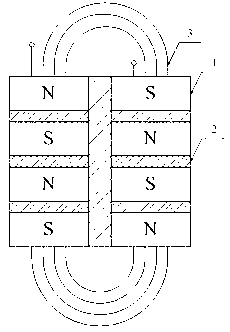

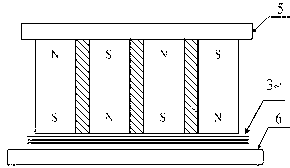

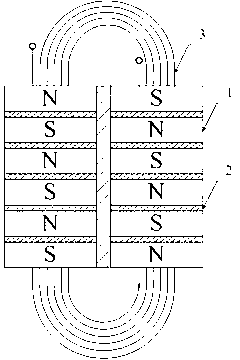

[0023] Such as figure 1 , 2 As shown, the transceiving switchable SH guided wave electromagnetic ultrasonic probe consists of eight permanent magnets 1, three racetrack-shaped planar coils 3 with the same geometric dimensions, a non-magnetic material sheet 2, a carbon steel sheet 5 on the top of the permanent magnet 1, and a probe protection layer , housing, capacitors C1, C2 and switches S1, S2, S3, S4, S5, 6 represents the workpiece to be detected.

[0024] Among them, the permanent magnet 1 is a NdFeB permanent magnet, and the magnetic poles of the eight permanent magnets 1 are alternately arranged and attached to the carbon steel sheet 5 on the top, and the magnets are separated by non-magnetic material sheets 2 (plastic sheets or paper sheets). A racetrack-shaped planar coil 3 is pasted on the lower end of the permanent magnet 1, and three racetrack-shaped planar coils 3 are connected with the switches S1, S2, S3, S4, S5 and capacitors C1 and C2. Figure 4 Form connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com