Collecting method for carbon and sulfur drilling cutting samples and collector

A technology of sample collection and carbon-sulfur drilling, applied in the direction of sampling devices, etc., can solve the problems of loss of samples, large amount of drilling samples, increase of drilling time, etc., and achieve the effect of saving time, reducing intermediate links, and saving drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

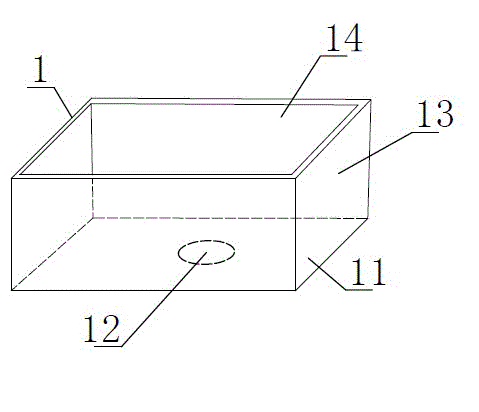

[0021] The carbon-sulfur drilling cuttings sample collection method of the present embodiment comprises the following steps, using a drill press to drill off the surface sample cuttings of the sample; a carbon-sulfur drilling cuttings sample collector is placed above the sample, and the collector is provided with a passage for the drill bit to pass through The drill bit drills into the sample through the through hole, and the drill cuttings of the sample are discharged upward through the chip removal groove of the drill bit and fall into the collector; after the collector finishes collecting the sample, it is directly taken to the analysis room together with the collector for analysis sample.

[0022] see figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com