12.5Mpa pressure resistant array and production method thereof

A basic array and pressure technology, applied in the field of basic arrays, can solve problems such as poor reliability, oil leakage or liquid leakage, difficult maintenance, etc., to reduce wiring problems and improve the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

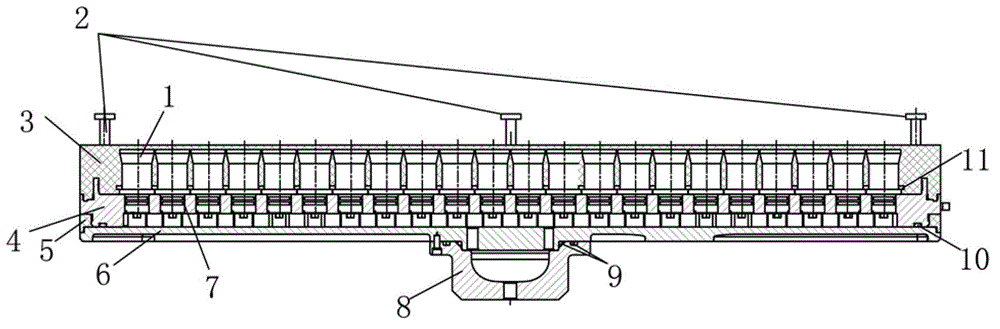

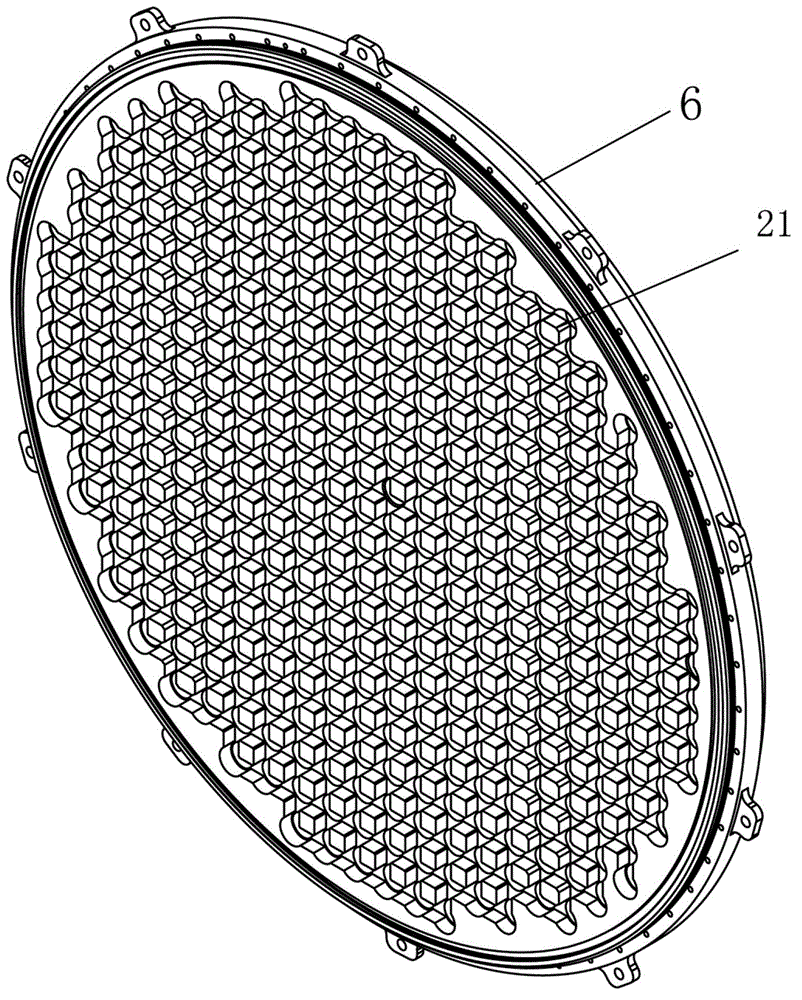

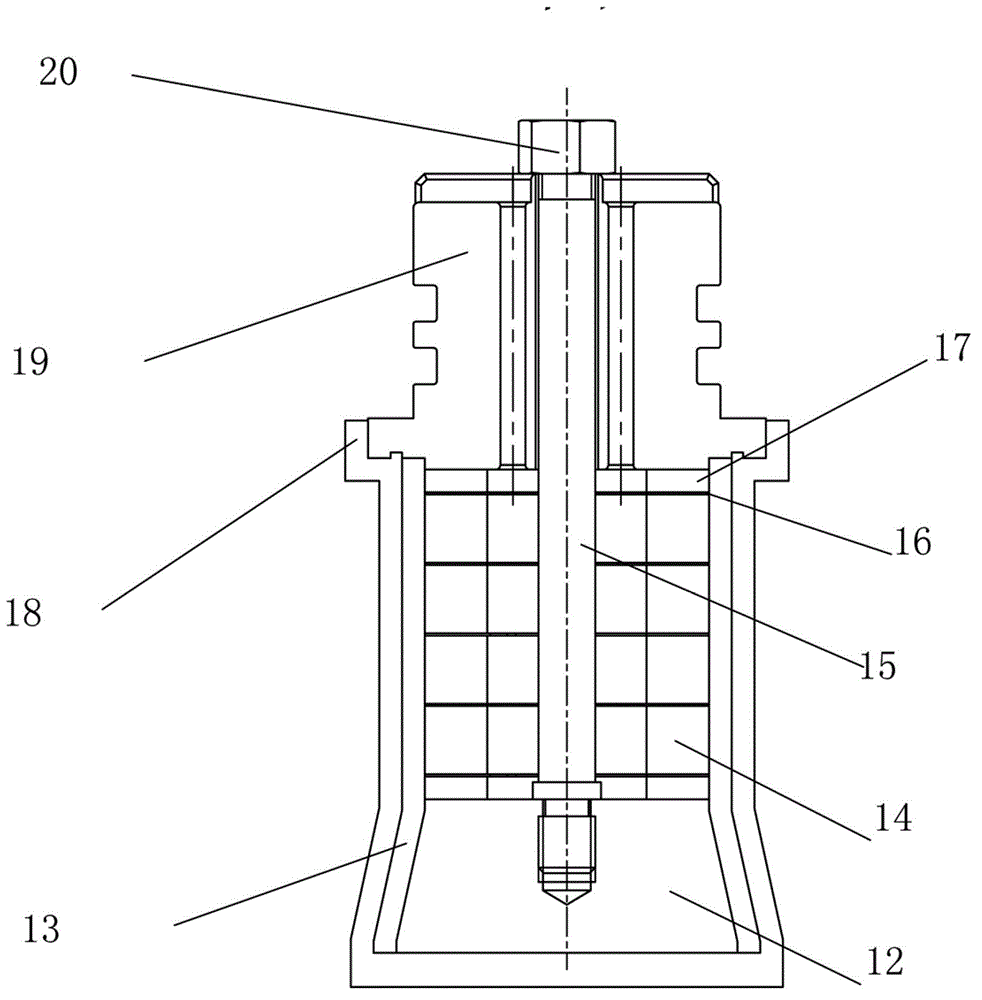

[0030] like Figure 1 to Figure 3 As shown, this array with a pressure resistance of 12.5MPa adopts a transducer 1 independent support and an array frame 4 grid-shaped pressure-resistant design, which ensures the watertightness and deep water resistance of the array. The transducer 1 is vulcanized and sealed separately, and is connected to the matrix shell through two first sealing rings 7 , and the transducer 1 adopts internal routing to lead out wires, which enhances the pressure resistance and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com