Gas-steam circulation combined double-stage coupling heat pump heat supply device

A heating device and coupled heat pump technology, applied in hot water central heating systems, household heating, heating methods, etc., can solve problems such as energy loss, achieve the effects of sufficient heat, improved cycle efficiency, and reduced exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

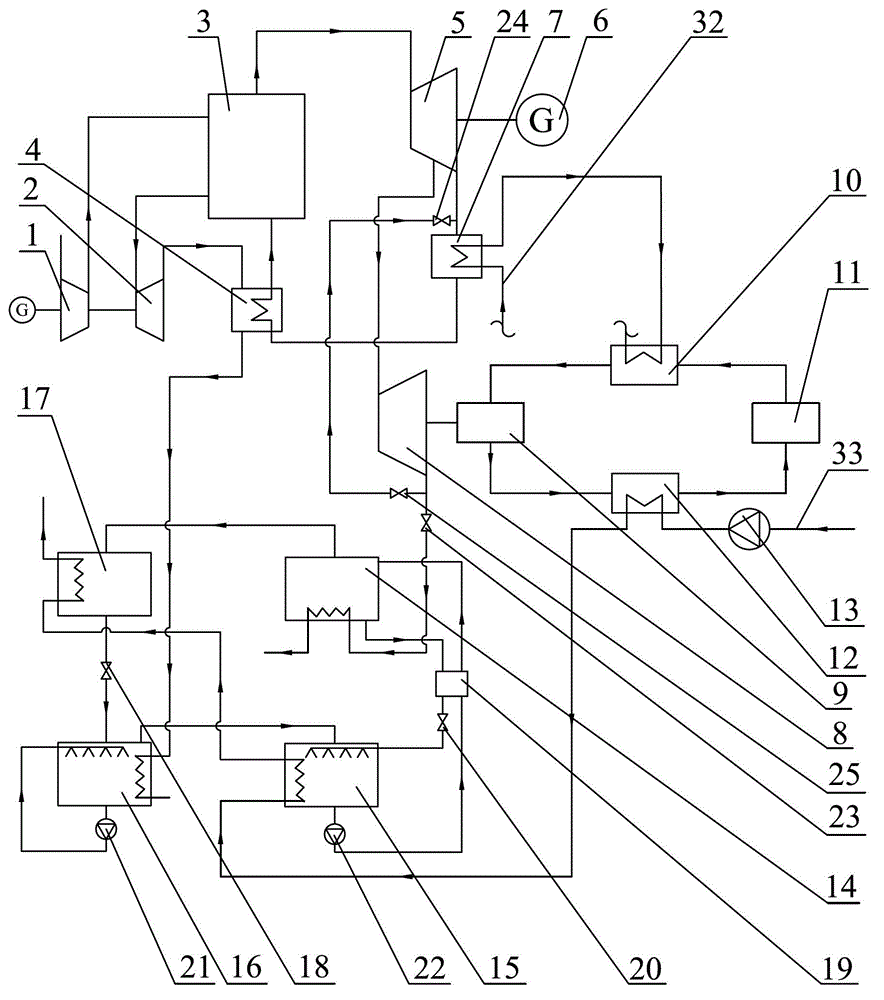

[0021] Embodiment 1: Combining figure 1 Illustrating this embodiment, the gas-steam cycle combined two-stage coupled heat pump heating device of this embodiment, the gas-steam cycle power generation system includes a compressor 1, a gas turbine 2, a boiler 3, a feed water heater 4, a power generation steam turbine 5, and a power generation system. 6 and condenser 7; the compression heat pump system includes a small steam turbine 8, a compressor 9, a first evaporator 10, a throttling mechanism 11 and a first condenser 12; the absorption heat pump system includes a generator 14 , absorber 15, second evaporator 16, second condenser 17, heat exchanger 18, throttle valve 19, solution valve 20, working fluid pump 21, solution pump 22, solution valve 23, first bypass valve 24 and the second bypass valve 25;

[0022] The compressed air outlet of the compressor 1 is connected with the compressed air inlet of the boiler 3 through the pipeline, and the flue gas outlet of the boiler 3 is...

specific Embodiment approach 2

[0024] Specific implementation mode 2: Combining figure 1Describing this embodiment, the water outlet of the absorber 15 in this embodiment is communicated with one of the two water inlets of the throttle valve 19 through a pipeline, and the pipeline between the absorber 15 and the throttle valve 19 is provided with a solution One of the two water outlets of the pump 22 and the throttle valve 19 is communicated with the water inlet of the generator 14 through a pipeline, and the water outlet of the generator 14 is communicated with the other water inlet of the throttle valve 19 through a pipeline. The other water outlet of the flow valve 19 is communicated with the water inlet of the absorber 15 through a pipeline, and a solution valve 20 is arranged on the pipeline between the other water outlet of the throttle valve 19 and the water inlet of the absorber 15. The water outlet of the evaporator 16 is communicated with the water inlet of the second evaporator 16 through a pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com