Process for brewing table vinegar

A technology, vinegar technology, applied in the field of solid-state fermentation vinegar brewing technology, can solve the problems of unfavorable esterification reaction, short esterification temperature time, large quality fluctuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A vinegar brewing process includes the following steps:

[0033] 1. Raw material moisturizing: crush the high-quality grain raw materials corn, rice, wheat, sorghum and buckwheat, and put them into the mixing tank to moisten and soak for 30 minutes;

[0034] 2. Cooking: The raw materials after moistening are heated to 95-98℃ in the mixing tank to liquefy;

[0035] 3. Saccharification and alcoholization: Daqu saccharifying agent is added to the clinker after cooking to carry out saccharification and alcoholization to prepare alcoholic mash;

[0036] 4. Acetic acid fermentation: mix wheat bran, chaff and other auxiliary materials with wine mash, connect black koji and acetic acid strains for multi-strain fermentation to produce vinegar, the cycle is 25-30 days, and the acid production rate is about 7 g / 100ml .

[0037] 5. After the fermentation is over, add salt to the mash to get mature vinegar;

[0038] 6. Pour the vinegar: move the mature vinegar into the vinegar bath, add tap w...

Embodiment 2

[0056] The steps 1 to 6 are the same as in Example 1.

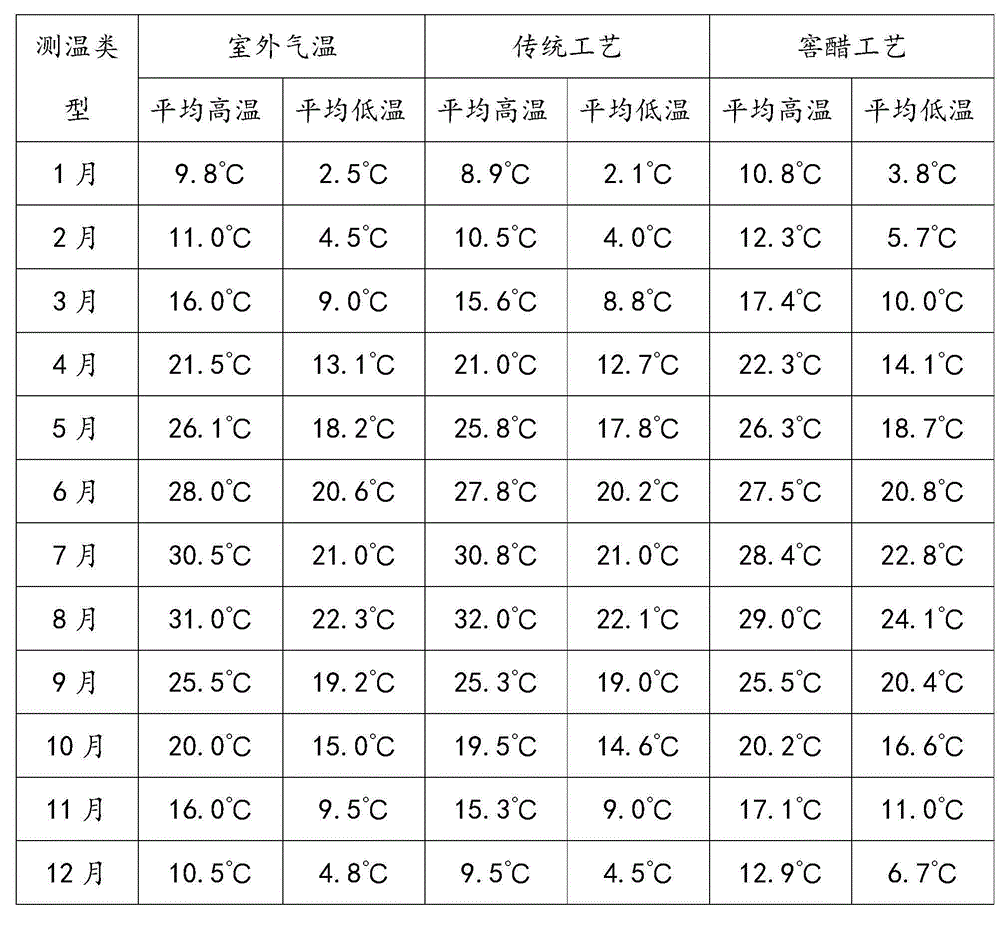

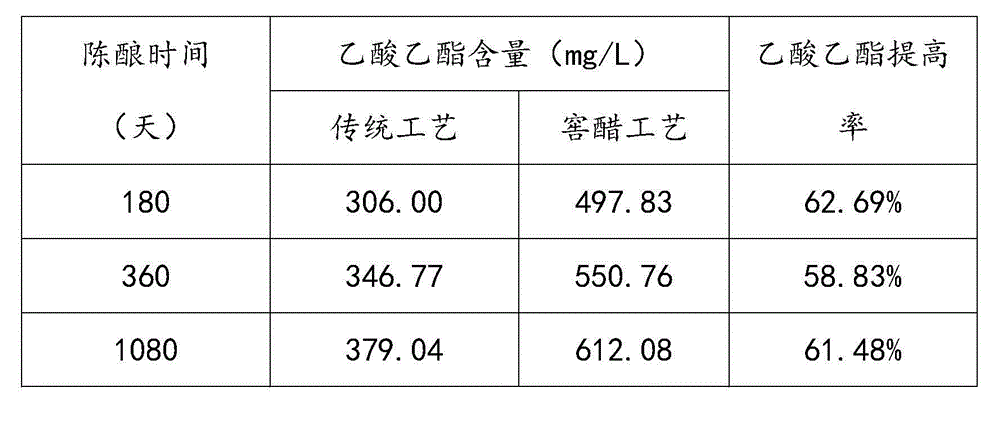

[0057] Seven, raw vinegar aging, put the leached raw vinegar into several 500L earthenware pots with a capacity of 400L raw vinegar per pot. On the same day, cellaring and aging of the same batch of vinegar began. The depth of the pot body buried in the soil is based on the ratio of the volume of the pot above the ground to the volume below the ground.

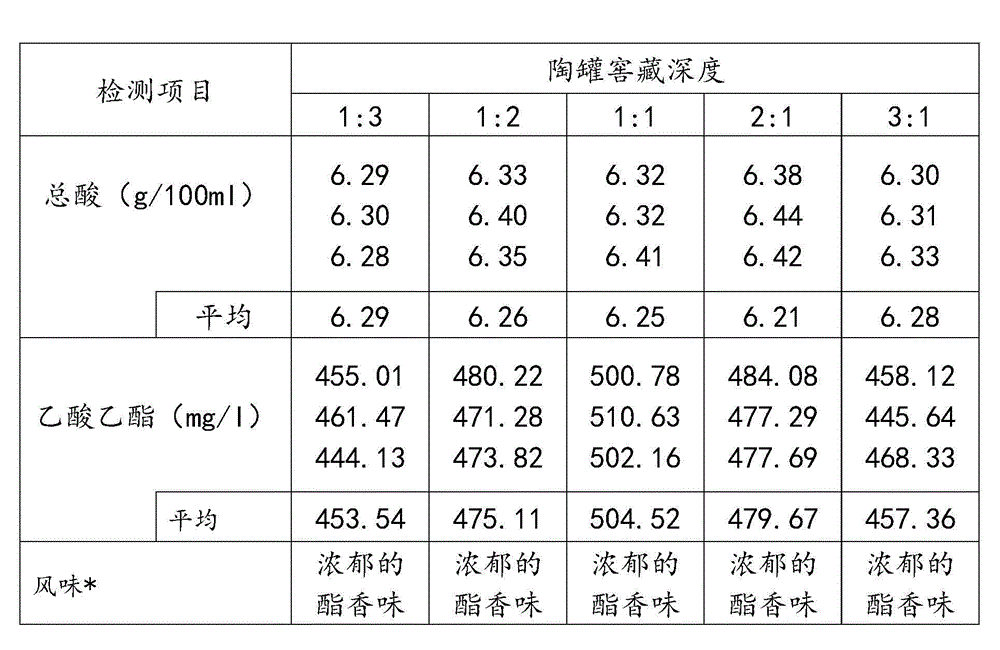

[0058] Select the volume ratio of the volume of the part above the ground to the part below the ground (cellar depth) as 1:3, 1:2, 1:1,2:1, 3:1.

[0059] The pitting time of the pit vinegar process of the present invention is 180 days, and the total acid, non-volatile acid, and ethyl acetate of the vinegar prepared at different depths of the container buried in the soil are detected. The specific values are shown in Table 3 below.

[0060]

[0061] table 3

[0062] It can be seen from the above table that when the cellar depth is between 1:2 and 2:1, there is no significant d...

Embodiment 3

[0064] The steps 1 to 6 are the same as in Example 1.

[0065] Seven, raw vinegar aging, put the leached raw vinegar into several 200L-2000L earthenware pots, and the original vinegar can fill 80% of the volume of the earthenware pot. On the same day, the vinegar of the same batch of different canned quantities will be stored and aged. The volume ratio of the volume of the part above the ground to the part below the ground is 1:1, and the storage time of the pots with volumes of 200L, 500L and 1000L is 180 The storage time of a 2000L clay pot is 360 days.

[0066] The total acid and ethyl acetate of the vinegar prepared by using containers with different volumes in the pit vinegar process of the invention to be buried in the soil for different aging times are detected. See Table 4 below for details.

[0067]

[0068] Table 4

[0069] The use of smaller pots will bring huge inconvenience and higher labor costs to actual production. If pots larger than 1000L are used, it will take lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com