Device and method for dehydrating crude oil

A crude oil dehydration and crude oil technology, which is applied in hydrocarbon oil dehydration/demulsification, petroleum industry, etc., can solve the problem of inability to obtain high temperature and high pressure physical property characteristic parameter data of crude oil fluid, and achieve the effect of accelerating the layering speed and facilitating drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

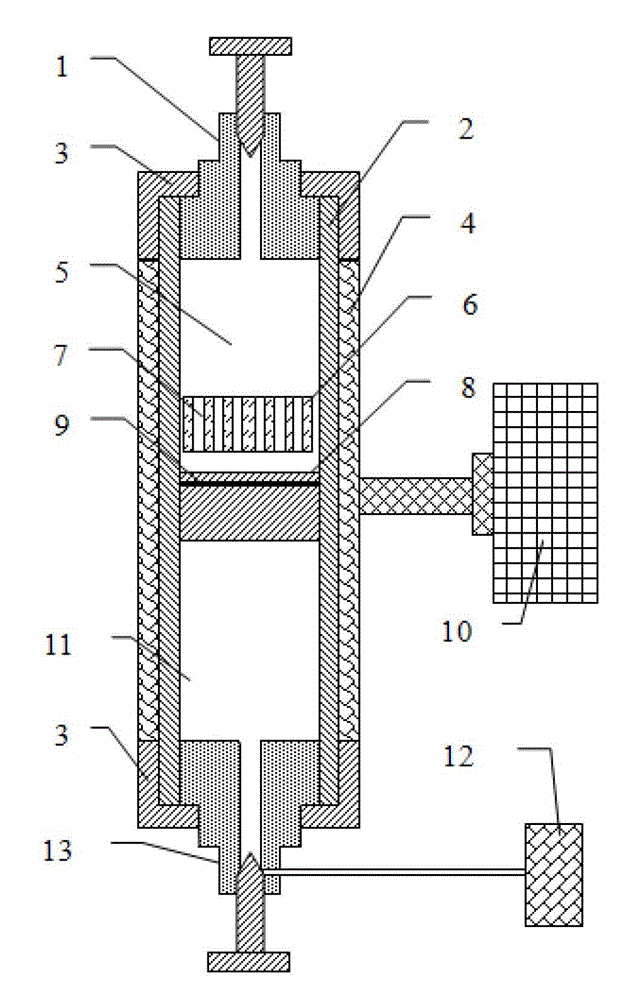

[0026] A crude oil dehydration device, mainly composed of a reactor 2, a crude oil sample chamber 5, an agitator 6, a piston 8, and a pressure transmission liquid chamber 11, the piston 8 is located in the reactor 2 and divides the inner chamber of the reactor into crude oil The sample chamber 5 and the pressure transmission liquid chamber 11, the crude oil sample chamber has a stirrer 6, and the reaction kettle 2 has a heating insulation jacket 4 outside, and the reaction kettle 2 is connected with a rotation control system 10, so that it can rotate along the vertical direction. Rotate 180 degrees; the pressure transmission liquid chamber 11 is connected to the power system 12, and the power system pressurizes the water-containing crude oil in the kettle through the pressure transmission liquid chamber 11 and the piston 8; the reaction kettle 2 has a reaction kettle cover 3 and a Valves, the valve 1 at the crude oil sample chamber end is used for sample injection and sample di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com