Apparatus and method for producing aminoanisole by reduction of sodium hydrosulfide

A technology of aminoanisole and sodium hydrosulfide, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxyl compounds, etc., can solve the problems of low production capacity, high production cost, and high labor intensity of the intermittent reduction device , to achieve the effects of strengthening direct mechanical shearing, high production efficiency, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

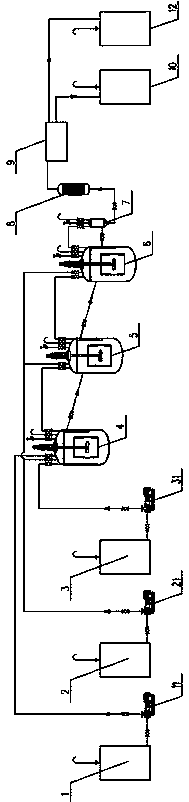

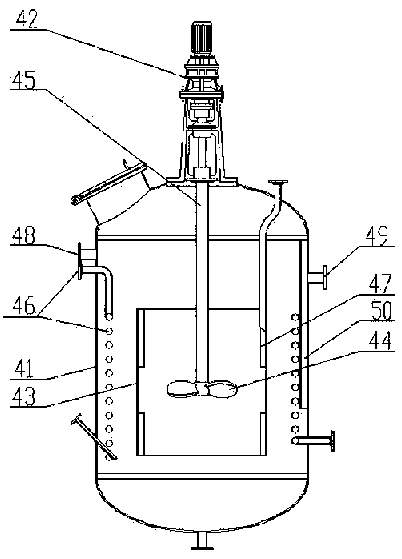

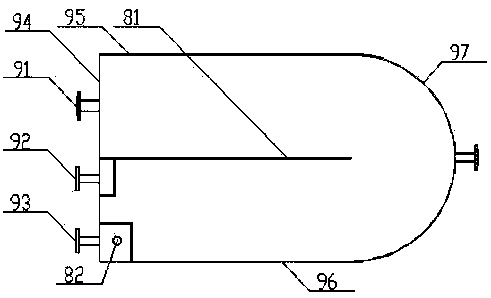

[0025] A device and method for reducing sodium bisulfide to produce aminoanisole, comprising nitroanisole storage tank 1, sodium bisulfide storage tank 2, liquid caustic soda storage tank 3, primary reduction kettle 4, and secondary reduction kettle 5 , three-stage reduction kettle 6, discharge liquid level control tank 7, reducing liquid cooler 8, reducing liquid separator 9, aminoanisole storage tank 10, waste water storage tank 11, said primary reduction kettle 4, secondary The reduction kettle 5 and the three-stage reduction kettle 6 have the same structure. The first-stage reduction kettle 4 includes a housing 41, a transmission device 42, a guide tube 43, a stirring blade 44, a stirring shaft 45, and a heat exchange coil 46. The transmission The device 42 is fixed on the top of the housing 41 through a bracket, the guide tube 43 is suspended in the housing 41 through the bracket, the inner wall of the guide tube 43 is provided with a radial baffle 47, and the stirring bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com