Method for modifying ZSM-5 zeolite material

A technology of ZSM-5 and treatment method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of reducing the catalytic activity of zeolite, low micropore surface area, and low mesopore specific surface area and other issues to achieve the effect of increasing the BET surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

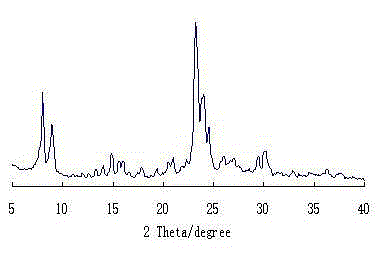

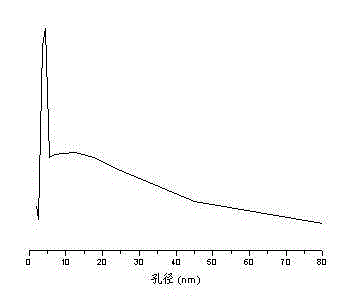

[0031] Take 30 g of microporous ZSM-5 zeolite, 1200 mL of 0.60 mol / L KOH solution, and 75 mL of methanol and mix them thoroughly, then place them in a microwave digestion apparatus for 30 min, keep the temperature at 90 ° C; then filter and wash. Put the washed ZSM-5 zeolite in a beaker, add 900mL of 0.2mol / L nitric acid solution, stir at room temperature for 20min, transfer to a water bath at 90°C for 2h, filter and wash, then place in an oven for 110 ℃ drying for 12h, the obtained sample number is CL1.

Embodiment 2

[0033] Take 30 g of microporous ZSM-5 zeolite, 1200 mL of 0.50 mol / L KOH solution, and 90 mL of ethanol and mix well, then place it in a microwave digestion apparatus for 20 minutes, keep the temperature at 100 °C; then filter and wash. Put the washed ZSM-5 zeolite in a beaker, add 900mL of 0.2mol / L nitric acid solution, stir at room temperature for 20min, transfer to a water bath at 80°C for 2h, filter, wash, and place in an oven at 110°C After drying for 12 hours, the obtained sample number is CL2.

Embodiment 3

[0035] Take 30 g of microporous ZSM-5 zeolite, 2100 mL of 0.50 mol / L NaOH solution, and 150 mL of propanol and mix them thoroughly, then place them in a microwave digestion apparatus for 30 minutes, and keep the temperature at 70 ° C; then filter and wash. Put the washed ZSM-5 zeolite in a beaker, add 1500mL of 0.8mol / L sulfuric acid solution, stir at room temperature for 20min, transfer to a water bath at 70°C for 2h, filter, wash, and place in an oven at 110°C After drying for 12 hours, the obtained sample number is CL3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com