Method for preparing cellular silicon dioxide nanotubes

A silicon dioxide, honeycomb technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problem that honeycomb silicon dioxide nanotubes have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

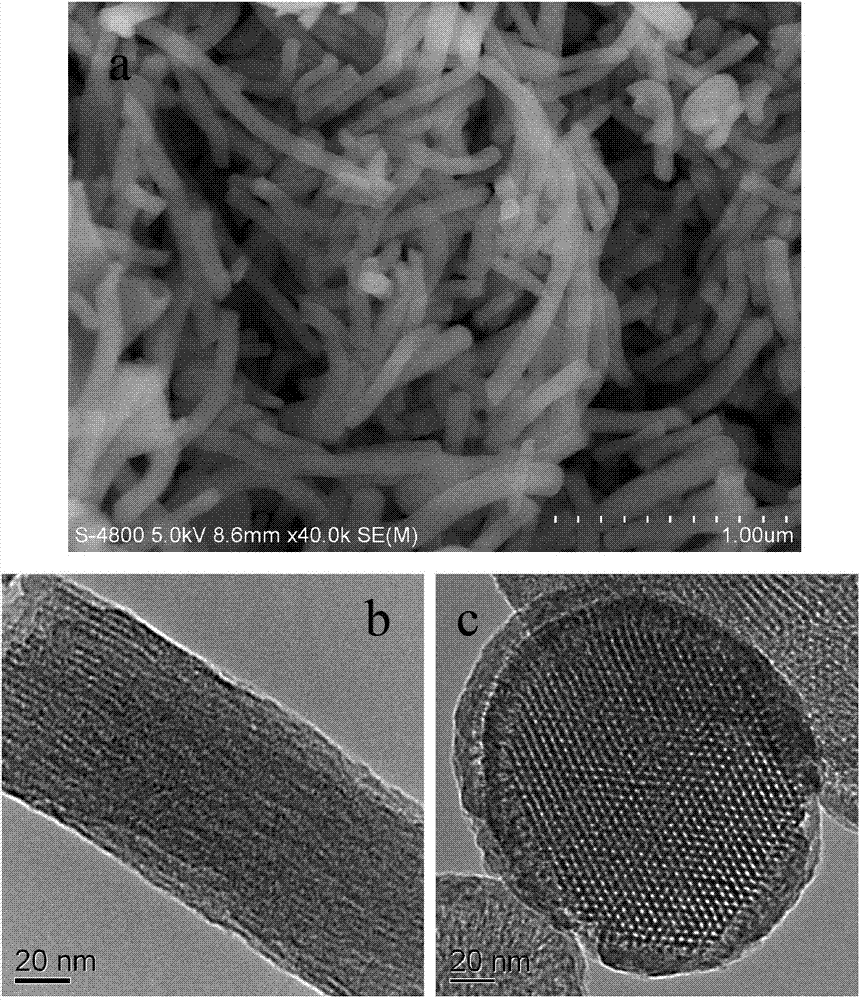

[0023] Dissolve CTAB and P123 in 100ml of concentrated ammonia water with a mass fraction of 25%, heat to 60°C and keep the temperature constant, stir until clarification at a stirring speed of 550rpm, add 1.5ml TEOS, continue stirring for 6 hours, and dissolve the reacted solid-liquid The mixture was transferred to a Teflon-lined stainless steel autoclave with hydrothermal heating. The resulting product was centrifuged, washed, dried, and then roasted at 550°C for 6h to remove the surfactant. where CTAB:P123:H 2 O: SiO 2 : NH 3 The molar ratio is 0.4:0.005:566:1:200. From figure 1 In -a, it can be seen that the surface of the obtained product is smooth and regular, with a length of about 0.8 μm and a thickness of about 120 nm. Depend on figure 1 -b and 1-c, it can be seen that the pores of silica nanotubes are regular and obviously honeycomb.

example 2

[0025] The operation is the same as in Example 1, except that the amounts of CTAB and P123 are changed to obtain honeycomb silica nanotubes with a length of about 1 μm and a thickness of about 200 nm. where CTAB:P123:H 2 O: SiO 2 : NH 3 The molar ratio is 2.4:0.02:566:1:200.

example 3

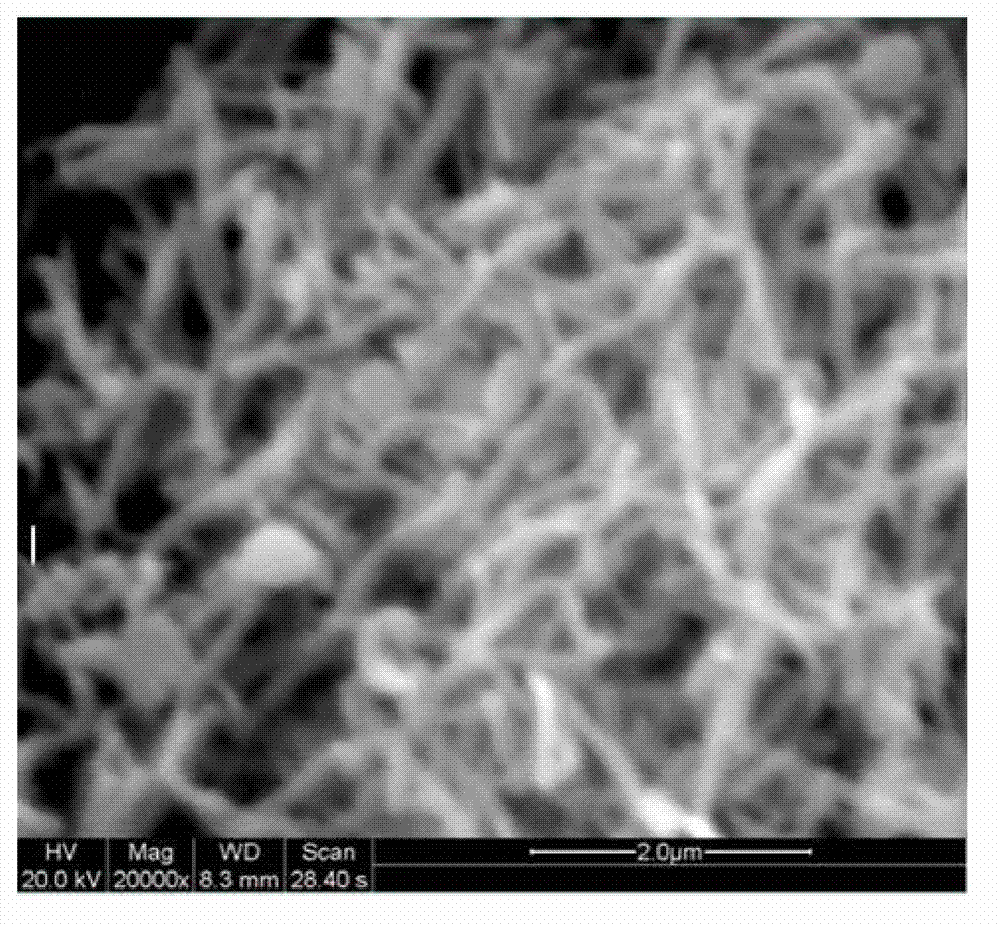

[0027] The operation is the same as in Example 1, except that the amount of CTAB, P123 and TEOS is changed, the mass fraction of ammonia water is 1%, and the rotation speed is 50 rpm. Depend on figure 2 It can be seen that the obtained honeycomb silica nanotubes have a smooth surface and good regularity, the length is about 5 μm, and the thickness is about 60 nm. where CTAB:P123:H 2 O: SiO 2 : NH 3 The molar ratio is 0.15:0.01:560:1:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com