Acidic CO2 flux-cored wire with ultralow hydrogen content and high toughness and preparation thereof

A technology of flux-cored welding wire and ultra-low hydrogen, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of complex manufacturing process, inability to realize all-position welding, and high content of diffused hydrogen in deposited metal, and achieve excellent cold resistance Crack performance, good moisture absorption performance, good effect of slag coverage

Active Publication Date: 2013-01-16

WUHAN TEMO WELDING CONSUMABLES CO LTD

View PDF9 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Flux-cored wire is divided into two types: "seamless" and "seamed" according to the shape of the seam. The manufacturing process of seamless flux-cored wire is more complicated, and the manufacturing process of seamed flux-cored wire is relatively simple. It is widely used at home and abroad, but due to Ordinary seamed flux-cored welding wire is easy to absorb moisture through the gap of the butt joint during the production process or after being placed for a period of time, resulting in a high content of hydrogen diffused in the deposited metal during the welding process. A large number of fatal cold crack defects are prone to occur when steel is welded

In addition, ordinary acidic flux-cored wires have high diffusible hydrogen content, poor crack resistance and low-temperature impact toughness, while basic flux-cored wires have low diffusible hydrogen content, but poor welding process performance and cannot achieve all-position welding, etc. This series of factors limit the wide use of flux-cored wire in the field of bridge steel welding in my country.

The published patents all reduce the diffusible hydrogen content of the flux-cored welding wire deposited metal by adjusting the flux core components. 2 It is very difficult for flux-cored wire to achieve ultra-low hydrogen content and prevent the core from absorbing moisture during production, use and after a period of time.

Method used

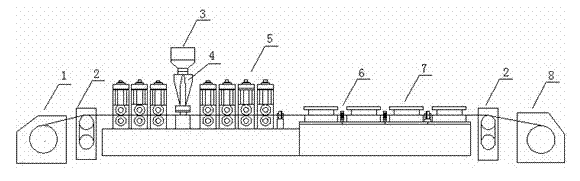

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an acidic CO2 flux-cored wire with ultralow hydrogen content and high toughness and preparation thereof. The flux-cored wire is used for bridge steel and consists of a carbon steel strip serving as a skin, and a medicinal core, wherein the medicinal core comprises the following main components in percentage by weight: 42 to 45 percent of TiO2, 2.5 to 3 percent of NaF, 4 to 6 percent of SiO2, 16 to 18 percent of Si-Mn, 3 to 5 percent of Al-Mg, 3 to 4 percent of MgO, 0.5 to 1 percent of ReF, 2 to 3 percent of ZrO2, 1 to 3 percent of Ti-Fe, 1.5 to 3 percent of Al-Fe, 2 to 3 percent of B-Fe and the balance of iron powder. The wire is subjected to on-line high-frequency heating and baking during preparation; and the flux-cored wire is simply, efficiently and controllably produced in batches and has high moisture absorption resistance, and high cold crack resistance during welding, deposited metal has the characteristics of high toughness and ultralow hydrogen content, all-position welding can be performed, a weld joint is high in slag coverage and slag detachability and small in welding spatter and has attractive appearance, and the flux-cored wire is suitable for welding bridge steel of grade 50kg in highly cold and highly humid severe environment and the like.

Description

Technical field [0001] The invention belongs to the technical field of welding materials, and specifically relates to an ultra-low hydrogen and high toughness acid CO for bridge steel 2 Flux cored welding wire and its preparation. Background technique With the development of welding technology, flux-cored welding wire has been widely used in the shipbuilding industry due to its high production efficiency, good process performance, excellent welding quality, beautiful weld shape, simple operation, easy automation and semi-automation, etc. application. According to the shape of the seam, flux-cored welding wire is divided into "seamless" and "seamed". The manufacturing process of seamless flux-cored wire is more complicated, and the manufacturing process of seam flux-cored wire is relatively simple, and it is more commonly used at home and abroad. Ordinary seam flux-cored welding wire is easy to absorb moisture through the joint gap during the production process or after being ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/368B23K35/40B21C9/00

Inventor 徐文福吕奎清赵华中

Owner WUHAN TEMO WELDING CONSUMABLES CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com