Flying shear device for finishing and shearing of thick metal strips

A strip and metal technology, which is applied in the field of flying shear device for trimming and shearing thick metal strips, can solve the problems of low production efficiency, small shear thickness range, and slow shear speed, etc., and achieve high production efficiency, The effect of increasing shear frequency and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

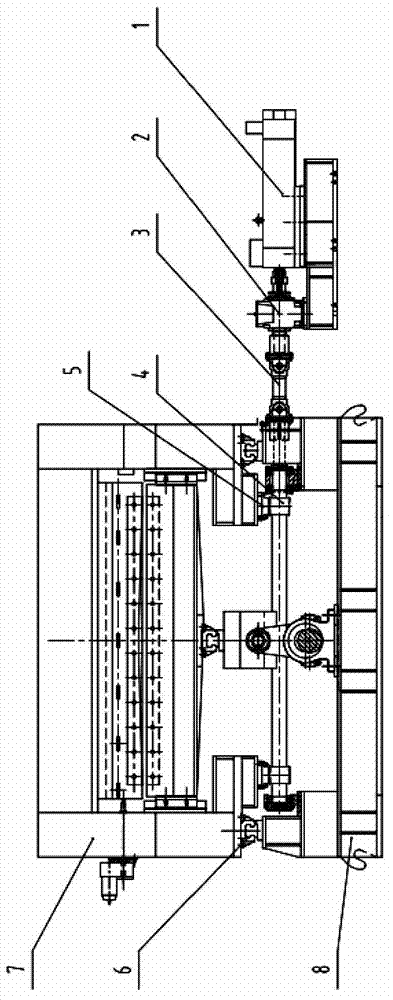

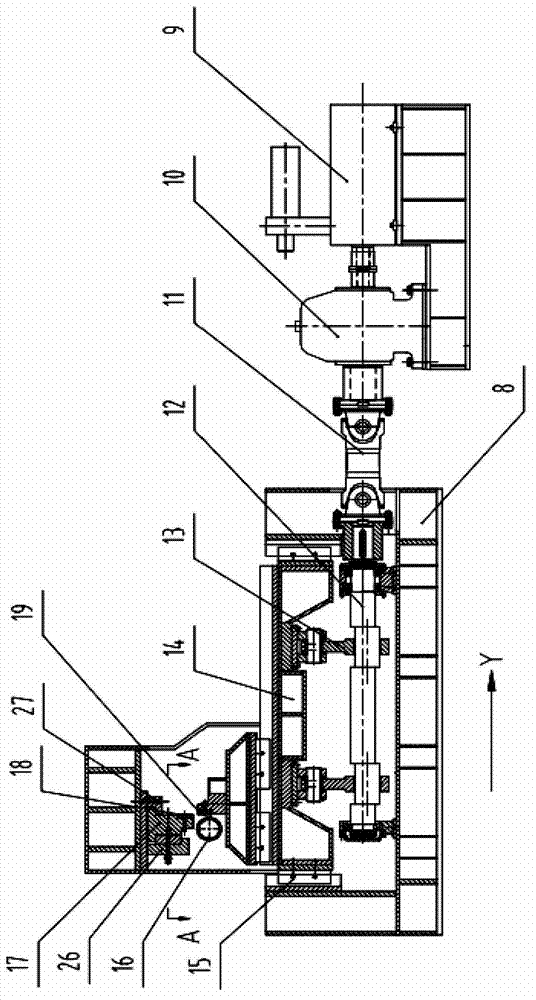

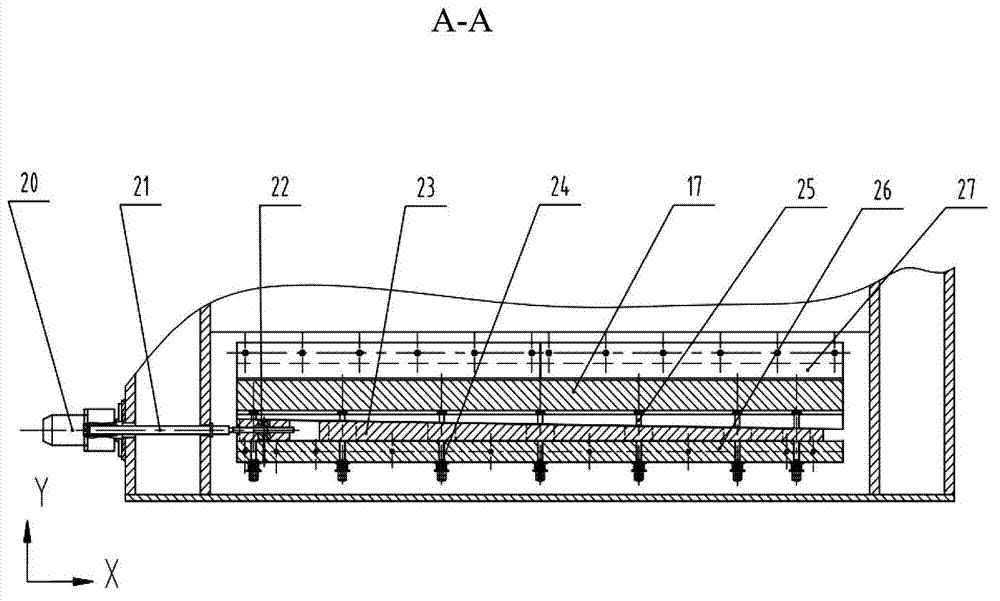

[0015] The flying shear device provided by the present invention is mainly composed of a main drive device, an eccentric link type shearing device and a cutter body gap adjustment device, wherein the main drive device includes: a main drive motor 1, a main drive reducer 2, a main drive Drive coupling 3, main drive gear shaft 4, main drive rack 5, main drive linear guide rail 6, beam 7 and base 8; the eccentric link type shearing device includes: shearing motor 9, shearing reducer 10, Shearing coupling 11, shearing eccentric shaft 12, shearing connecting rod 13, lower shearing seat 14, shearing linear guide 15, shearing roller 16, upper shearing clamp 17, upper knife body 18 and lower knife body 19 Knife body gap adjustment device includes: gap adjustment motor 20, gap adjustment screw 21, gap adjustment nut 22, wedge adjustment pad 23, disc spring 24, T-shaped screw 25, lower platen 26 and upper platen 27.

[0016] In an exemplary embodiment, the components of each device are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com