Automatic powder metering system and method

A metering system and powder technology, applied in chemical instruments and methods, mixing methods, dissolving, etc., can solve problems such as inability to quickly unload materials, and achieve the effects of saving batching time, improving work efficiency, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

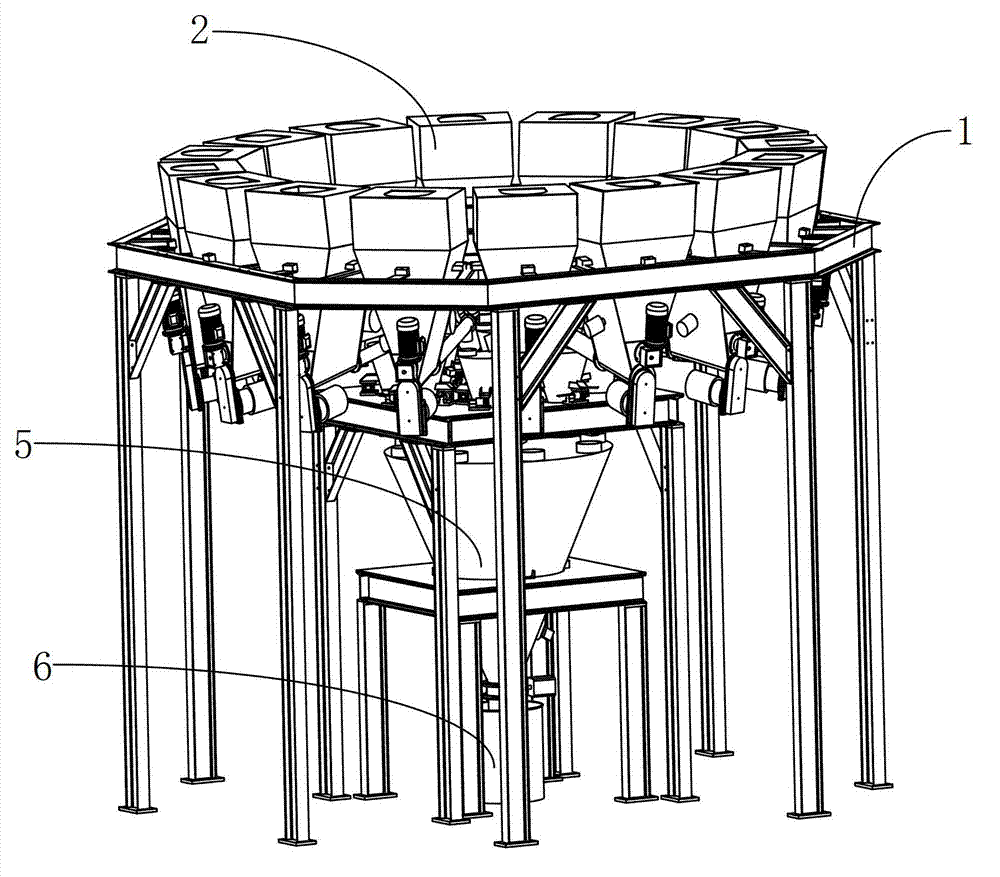

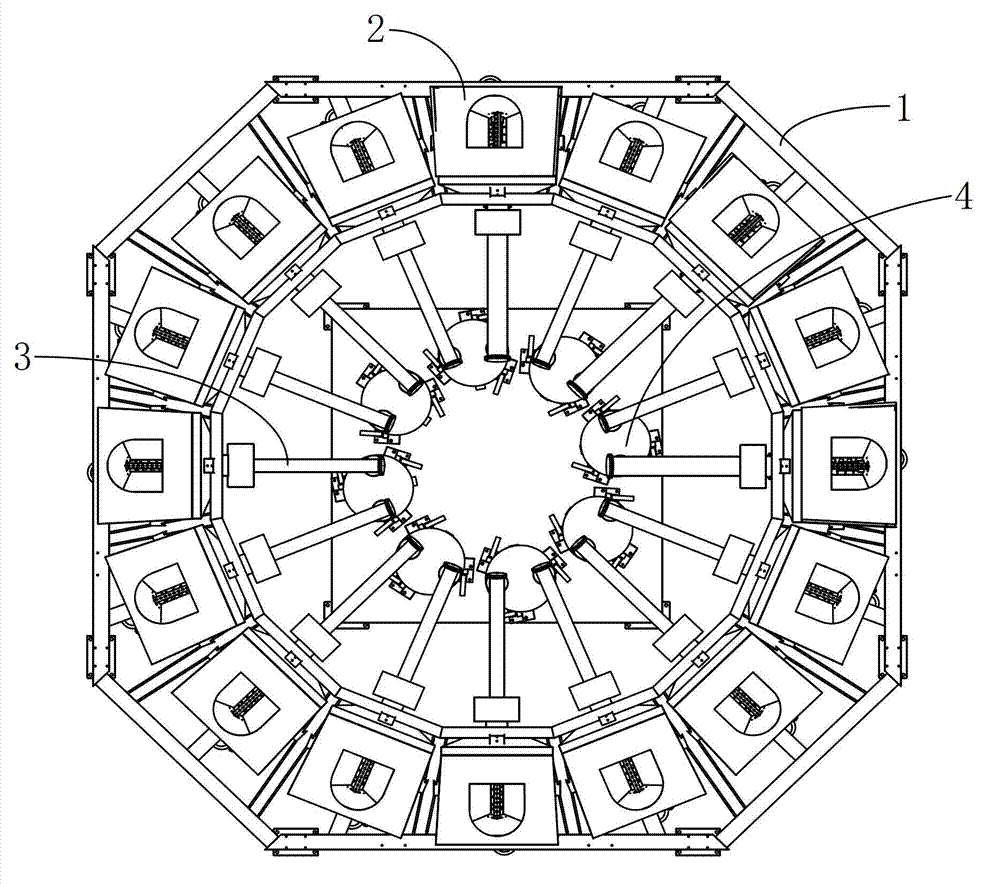

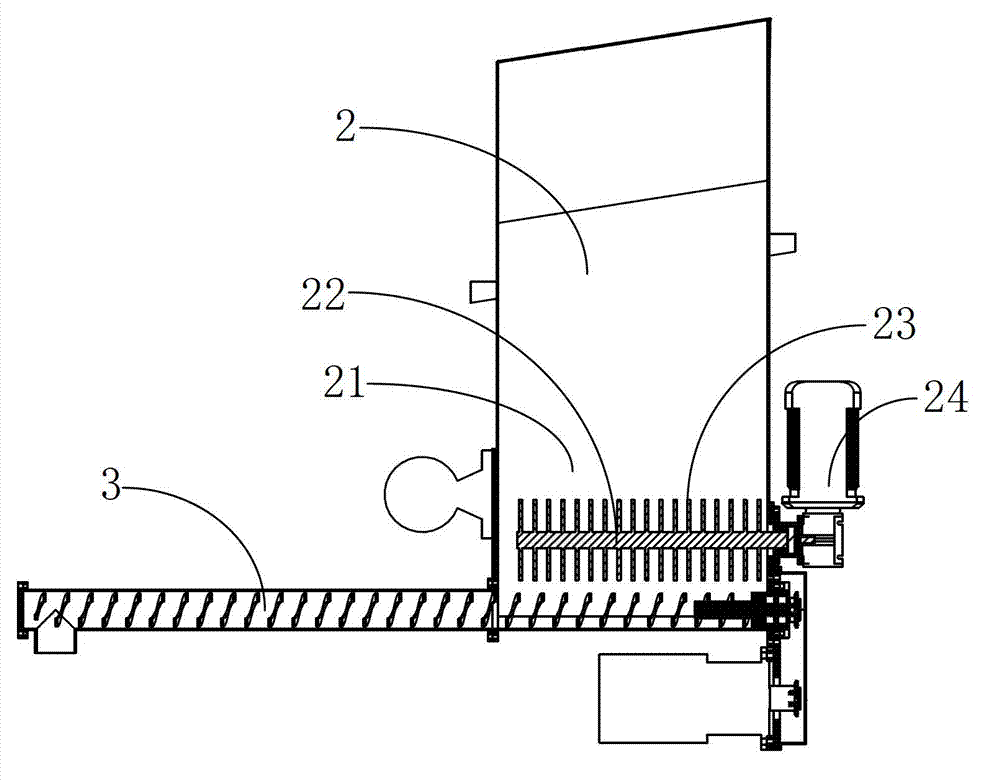

[0028] Powder automatic metering system provided by the present invention, such as figure 1 and figure 2 As shown, it includes: frame 1, several feed bins 2, several metering bins 4, several transmission mechanisms, temporary storage bins 5 and receiving boxes 6, and the several feed bins 2 are fixed on the frame 1 around a closed figure Specifically, in this embodiment, the several silos 2 are arranged in a circle around the frame 1, and the metering silos 4 are located below the silos 2 and pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com