Method for preparing CO2 catching membrane material with high hydrothermal stability

A thermally stable and high-performance technology, applied in the field of preparation of CO2 capture membrane materials, can solve the problems of inconspicuous separation effect and achieve good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

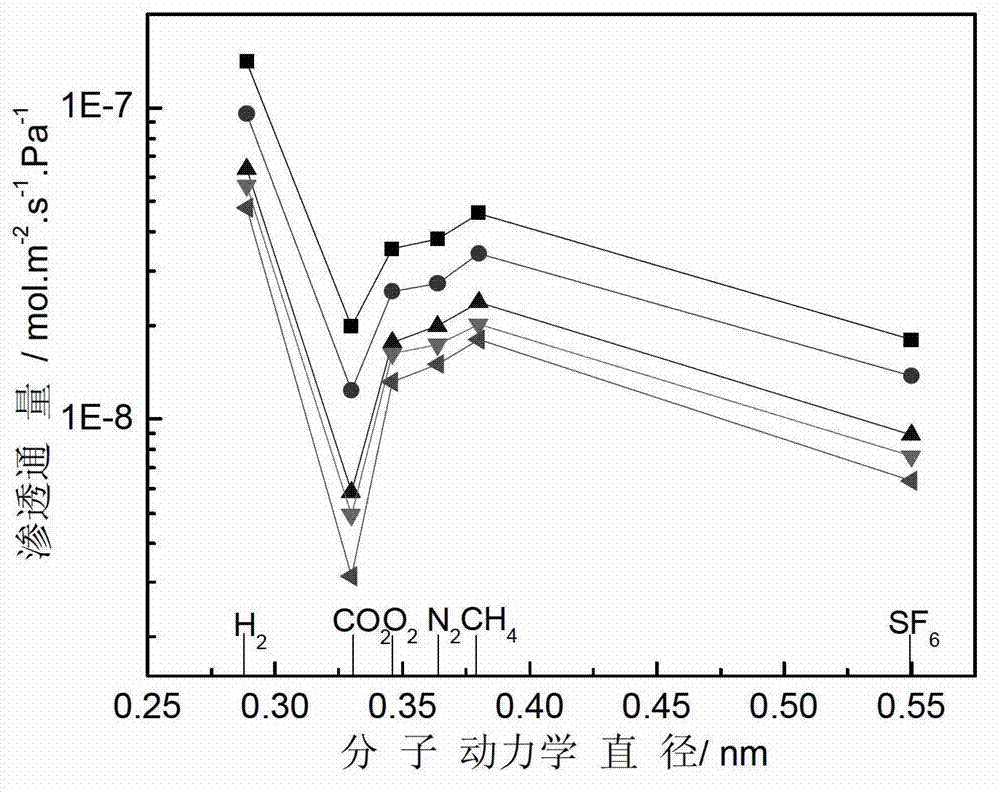

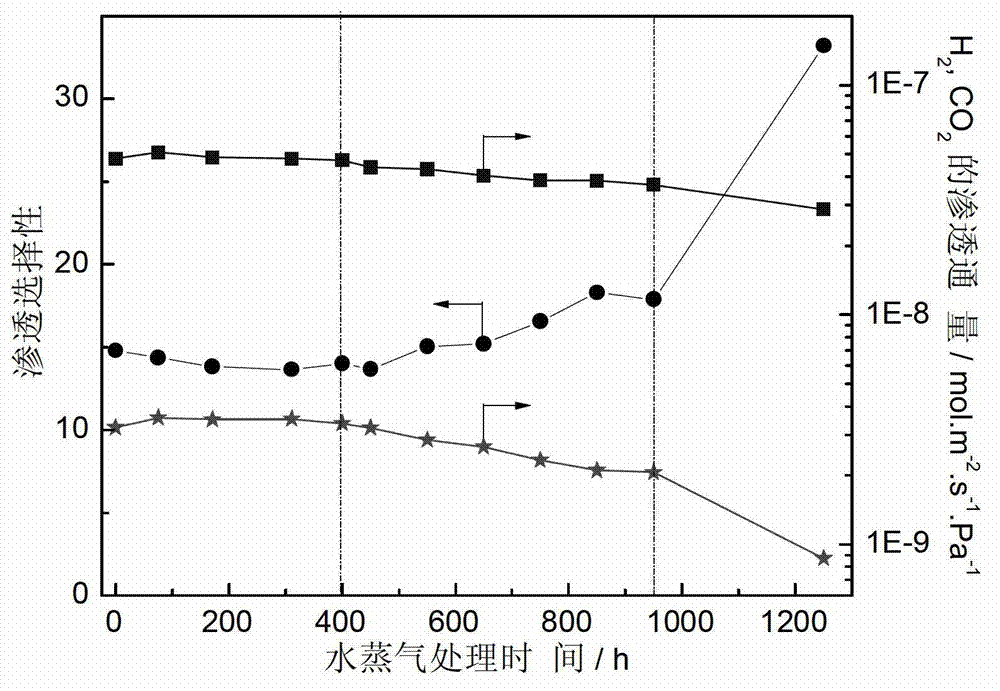

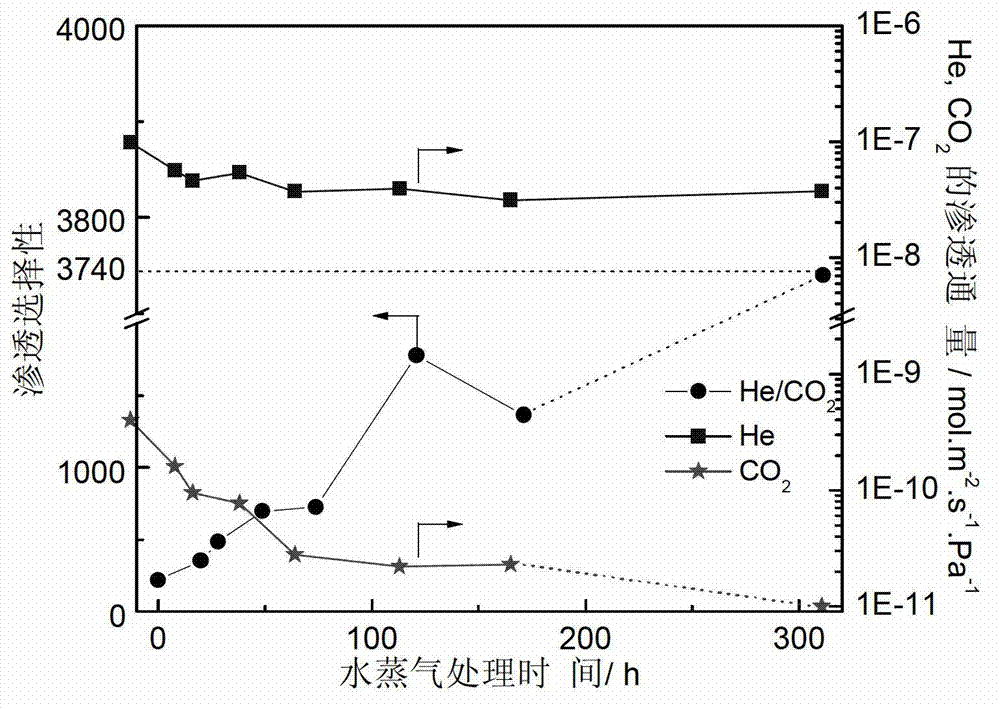

[0023] Mix 5ml (0.01mol) of zirconium n-propoxide, 35ml (0.47mol) of n-propanol and 10.3ml (0.1mol) of AcAc in an ice bath at 0°C and stir for 60 minutes, then add 3.6ml of (0.2mol) water, stirred for 20 minutes. After the reaction, ZrO with transparent appearance was obtained 2 Sol. Store it at -20°C until use. Mix the sol and absolute ethanol at a ratio of 1:3 by volume to obtain a film-forming solution, and place the film-forming solution in a sheet-shaped γ-Al 2 o 3 Membrane surface coating, naturally dried flaky ZrO 2The film was sintered at a heating rate of 2°C / min, and kept at 400°C for 8 hours before cooling down naturally to obtain ZrO 2 membrane. The gas permeability and hydrothermal stability of the membrane are as follows: figure 1 with figure 2 shown. from figure 1 It can be seen from the figure that at 200°C, the film is 2 The permeability can reach ~5×10 -8 mol.m -2 .s -1 .pa -1 , H 2 / CO 2 The selectivity exceeds the ideal separation factor o...

Embodiment 2

[0031] Mix 10ml (0.02mol) of zirconium isopropoxide, 1.2ml (0.02mol) of absolute ethanol and 0.2ml (0.002mol) of DEA in an ice bath at -10°C and stir for 1 minute, then add 10.8ml of (0.6mol) water, reacted for 60 minutes. After the reaction, ZrO with transparent appearance was obtained 2 Sol. Store it at -20°C until use. The sol and absolute ethanol were mixed with a volume ratio of 1:8 to obtain a film-making solution, and the film-making solution was placed in the flake TiO 2 Membrane surface coating, naturally dried flaky ZrO 2 The film was sintered at a heating rate of 1 °C / min, and after reaching 100 °C, it was kept for 1 hour and then cooled naturally to obtain ZrO 2 membrane. The membrane pairs H 2 The permeability reaches 4×10 -8 mol.m -2 .s -1 .pa -1 , H 2 / CO 2 The ideal separation factor is over 20, and it is stable for 125 hours at 200°C and 300kPa water vapor.

Embodiment 3

[0033] Mix 9ml (0.02mol) of zirconium n-butoxide, 40ml (0.44mol) of n-butanol and 40ml (0.39mol) of AcAc in an ice bath at -20°C. After stirring for 30 minutes, add 0.4ml of (0.022mol) water, react for 1 minute. After the reaction, ZrO with transparent appearance was obtained 2 Sol. Store it at -20°C until use. The sol and n-propanol are mixed with a volume ratio of 1:20 to obtain a film-making solution, and the film-making solution is placed in a sheet of ZrO 2 Membrane surface coating, naturally dried flaky ZrO 2 The film was sintered at a heating rate of 0.2°C / min, and after reaching 800°C, it was kept for 10 hours and then cooled naturally to obtain ZrO 2 membrane. The membrane pairs H 2 The permeability reaches 1.7×10 -8 mol.m -2 .s -1 .pa -1 , H 2 / CO 2 The ideal separation factor is over 20, and it is stable for 20 hours at 200°C and 500kPa water vapor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com