Milk chocolate and preparation method thereof

A chocolate and milk technology, applied in cocoa, food science, application, etc., can solve the problems of easy melting of chocolate, sticking into a ball, and inability to melt instantly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

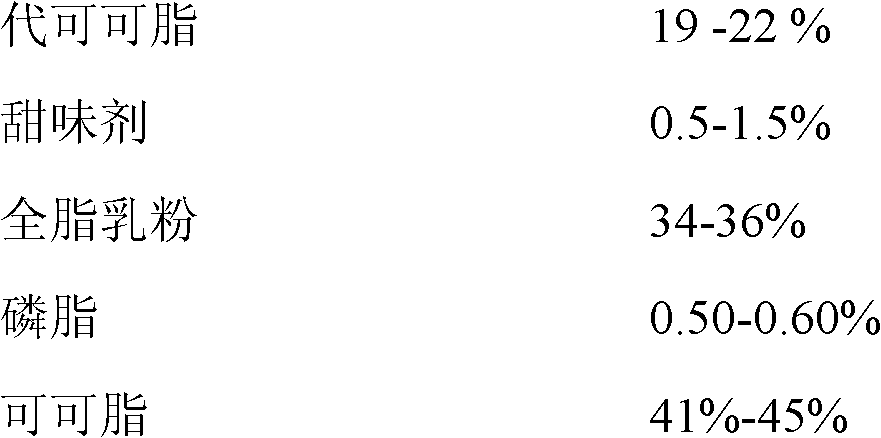

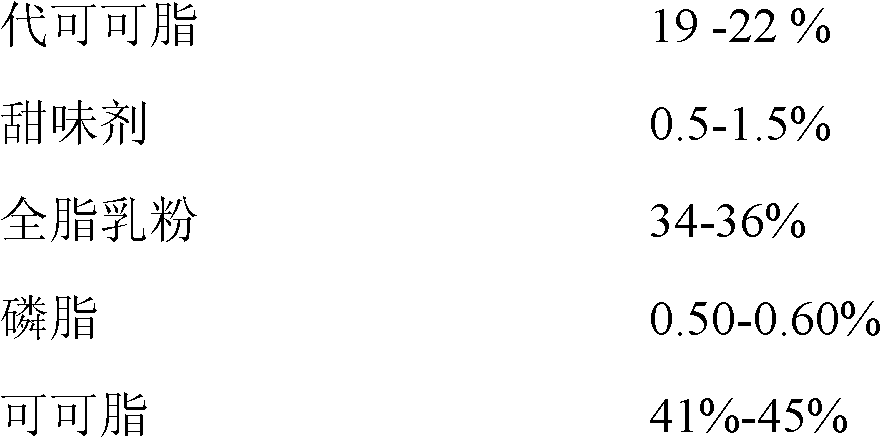

Embodiment 1

[0012] The raw materials are cocoa butter substitute 19%, sweetener 1.4%, whole milk powder 34%, phospholipid 0.60%, and cocoa butter 45%. First melt the cocoa butter substitute and cocoa butter at a temperature of 50°C. Then pour the whole milk powder together for fine grinding. After fine grinding, the average fineness is 30 microns. During the fine grinding process, the temperature is always kept at 43-46 ° C. During the fine grinding process, the current does not exceed 30 amperes, and the fine grinding time is 14 Hour. Then adjust the temperature, the temperature is always controlled at 43-46°C, and the temperature adjustment time is 10 hours. The raw materials are poured into the pouring machine for casting, and then the mold is released and packaged.

Embodiment 2

[0014] The raw materials are 21% cocoa butter substitute, 1.5% sweetener, 35% whole milk powder, 0.5% phospholipid, and 42% cocoa butter. First melt the cocoa butter substitute and cocoa butter at a temperature of 55°C. Then pour the whole milk powder together for fine grinding. After fine grinding, the average fineness is 29 microns. During the fine grinding process, the temperature is always kept at 43-46°C. During the fine grinding process, the current does not exceed 30 amperes, and the fine grinding time is 12 hours. . Then adjust the temperature, the temperature is always controlled at 43-46°C, and the temperature adjustment time is 9 hours. The raw materials are poured into the pouring machine for casting, and then the mold is released and packaged.

Embodiment 3

[0016] The raw materials are 22% cocoa butter substitute, 0.5% sweetener, 36% whole milk powder, 0.5% phospholipid, and 41% cocoa butter. First melt the cocoa butter substitute and cocoa butter at a temperature of 55°C. Then pour the whole milk powder together for fine grinding, the average fineness after fine grinding is 30 microns, the temperature is always kept at 43-46°C during the fine grinding process, the current during the fine grinding process does not exceed 30 amps, and the fine grinding time is 13 hours . Then adjust the temperature, the temperature is always controlled at 43-46°C, and the temperature adjustment time is 8 hours. The raw materials are poured into the pouring machine for casting, molded, and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com