System and method for detecting surface quality of coin mold

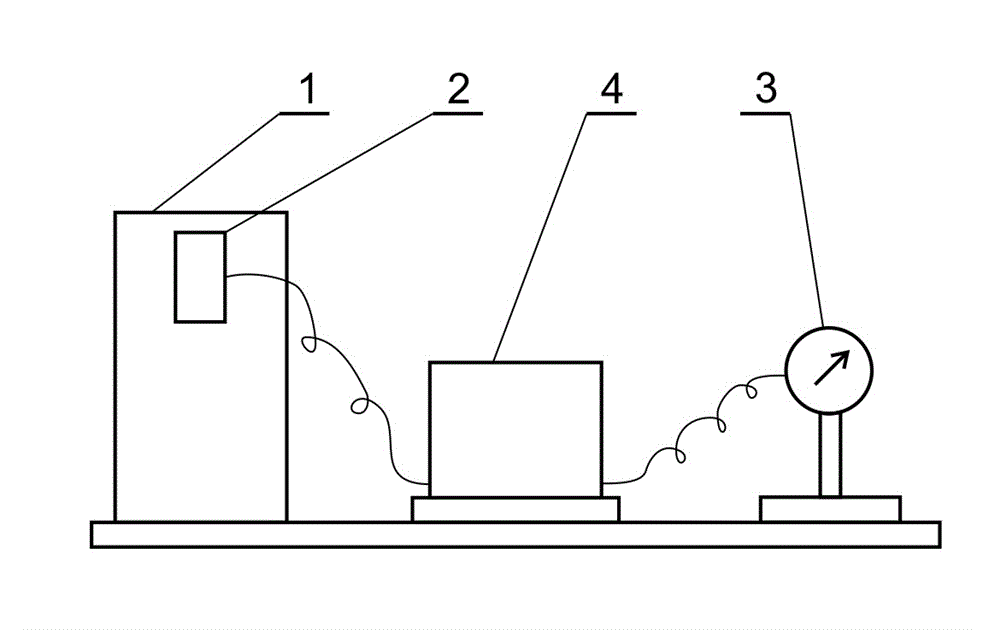

A surface quality and detection system technology, applied in the field of coinage, can solve the problems of difficult measurement and evaluation, easy to be affected by human factors, low detection efficiency, etc., achieve fast and accurate image comparison processing, and facilitate consistency control , image acquisition accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Taking the detection of circulation coin mold as an example

[0039] 1) Image detection

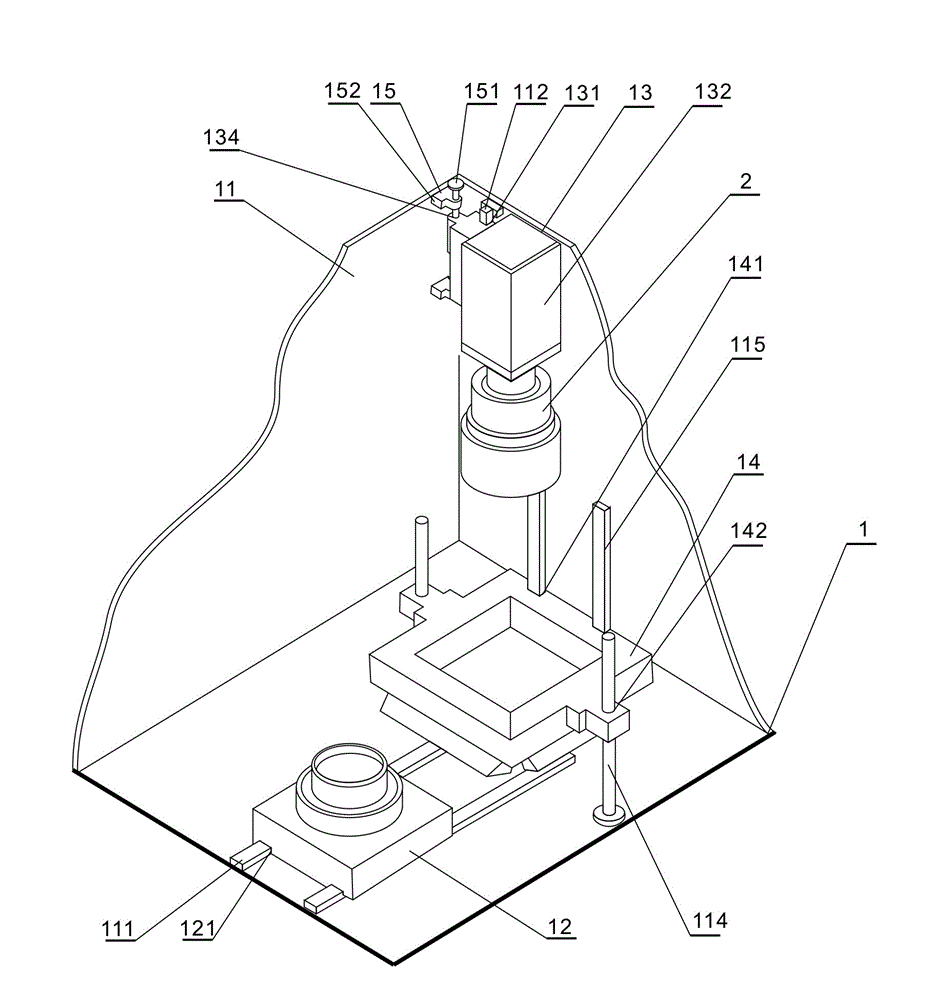

[0040] a) Preparatory work: determine the circulation coin mold to be tested, and store multiple standard images of the mold to be tested into the computer 4;

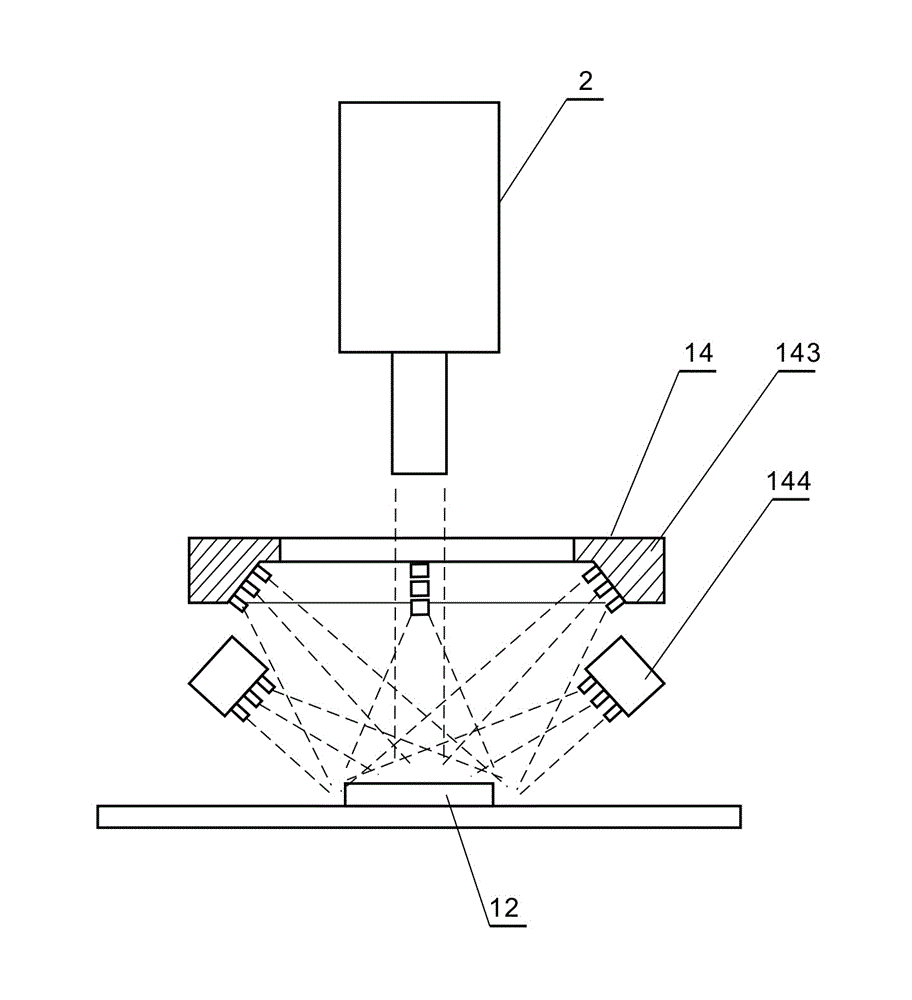

[0041] b) Configure the light source: match the corresponding light source bracket 14 according to the shape and position characteristics of the circulating coin mold to be detected;

[0042] c) Install the mold to be tested: move the mold station 12 to slide out from the mold rail 111 of the shell 11, place the front of the circulation coin mold to be tested in the mold station 12, and move the mold station in the opposite direction 12. Make it to enter the detection position for the circulation coin mold to be detected;

[0043] d) Adjusting the camera: adjust the screw 151 of the fine-tuning mechanism 15, through the meshing of the screw 151 and the fine-tuning nut 134, the camera bracket 13 is driven to slide on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com