Pull type direct pulling device

A lifting and straight-pulling technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of concrete core samples slipping and falling off, concrete core samples being crushed, etc., and achieve the effect of reducing the weight of the device and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

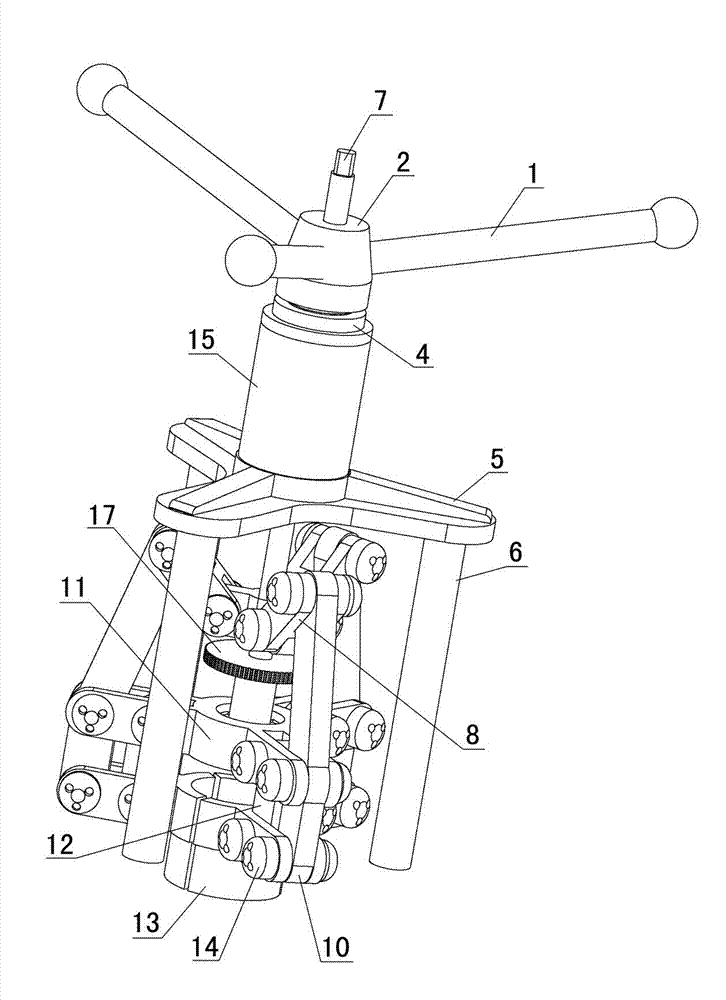

[0038] Examples see Figure 1-7As shown, this lifting type straight pulling device is composed of four parts: a straight pulling head, a reaction force frame, a pressure sensor 15 and a force application mechanism. Pulling the head, the reaction force frame, the pressure sensor 15 and the force applying mechanism are sequentially sleeved on the lifting rod 7 above the pulling head from bottom to top, and the force applying mechanism is also threaded with the lifting rod 7 . The lifting rod 7 between the pressure sensor 18 and the force applying mechanism is covered with a bearing seat 4 and a second bearing 3, and the function of the bearing seat 4 and the second bearing 3 is to reduce the friction between the force applying mechanism and the pressure sensor force.

[0039] The reaction force frame is composed of a support frame seat 5 sleeved on the lifting rod 7 and at least three support rods 6 fixedly connected to the lower surface of the support frame seat 5 .

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com