Fluidic impulse tee joint

A jet and three-way technology, applied in the direction of branch pipelines, gardening, pipes, etc., can solve the problems of long running time, complicated installation, use, maintenance, and high cost, and achieve enhanced anti-clogging ability, enhanced irrigation uniformity, and processing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

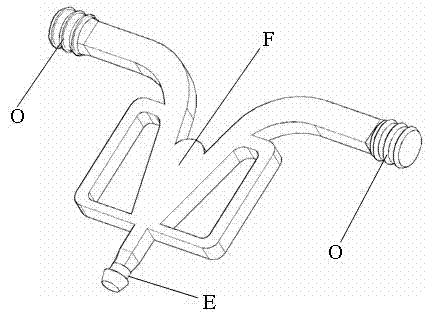

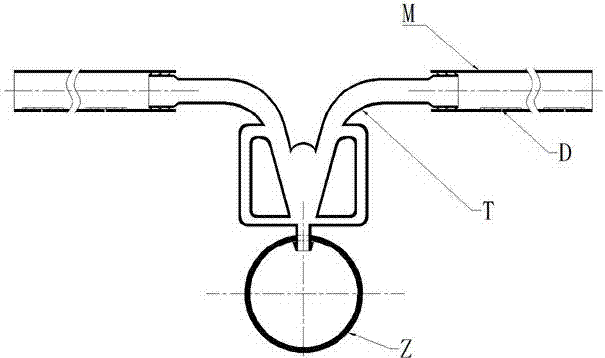

[0020] refer to figure 2 , the jet pulse tee is composed of an inlet section E, a jet element F and two outlet sections O.

[0021] refer to figure 1 , the jet element F includes jet nozzle 2, signal action port I3, signal action port II4, side wall I5, side wall II6, feedback channel I7, feedback channel II8, signal inlet I9, signal inlet II10, jet space 11, splitter splitter 12 , output port I13, output port II14, output channel I15, output channel II16; the front end of the jet element F is the nozzle 2, and the nozzle 2 is connected to the end of the water inlet section E; the side walls on both sides of the nozzle 2 are respectively symmetrically provided with signals Action port I3 and signal action port II4. Behind the nozzle 2 is a jet space 11 with a small front and a large rear. The two sides of the jet space 11 are side walls I5 and side walls II6 respectively; end, and the end of the jet space 11 is divided into output port I13 and output port II14; the signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com