Cooling and lubricating pipeline system for gear of gear box

A pipeline system, cooling and lubrication technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of reducing the performance of gearbox gears, lack of lubrication effect, non-flexibility, etc., to improve service life, simple and exquisite structure , Improve the effect of heat dissipation performance

Inactive Publication Date: 2013-01-09

ZHEJIANG BOSHITE MECHANICAL CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the transmission gears on automobiles are all equipped with lubrication pipelines, which are generally made of metal, do not have corresponding flexibility, and cannot extend to some inaccessible parts. In this way, these parts cannot reach Lubrication effect, which reduces the performance of transmission gears

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

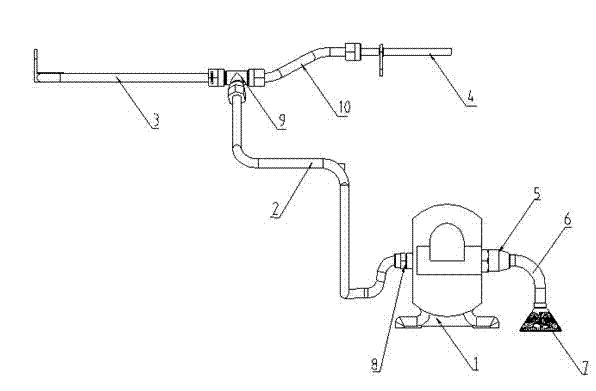

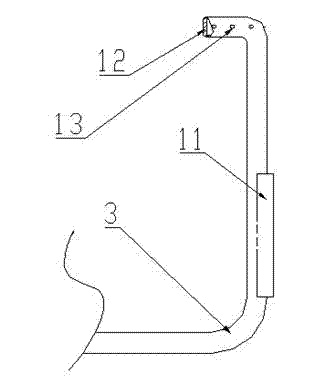

The invention discloses a cooling and lubricating pipeline system for a gear of a gear box. The cooling and lubricating pipeline system comprises a gear pump and a pipeline system, wherein the pipeline system comprises an oil pipe assembly, a front branch oil pipe assembly and a rear branch oil pipe assembly. The cooling and lubricating pipeline system has the advantages of simple and exquisite structure, flexibility, high heat dissipation and capability of fulfilling the aim of cooling during lubrication of the gear box.

Description

technical field [0001] The invention relates to a transmission gear cooling and lubricating pipeline system. Background technique [0002] In a car running on a steep slope, due to the transfer of lubricating oil to the downhill side, there is less lubricating oil on the uphill side, which can easily cause overheating of the gears and reduce service life. Lubricating oil provides lubrication for it. Mechanical lubricators include gears, bearings and synchronizers, etc. A good lubrication pipeline system can improve the life of gears, bearings and synchronizers, thereby improving the overall life of the transmission. At present, the transmission gears on automobiles are all equipped with lubrication pipelines, which are generally made of metal, do not have corresponding flexibility, and cannot extend to some inaccessible parts. In this way, these parts cannot reach Lubrication effect, which reduces the performance of the gearbox gears. It can be seen from the above that...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16H57/04

Inventor 冯波周志翔

Owner ZHEJIANG BOSHITE MECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com