Method and structure for micro-disturbance renovating of existing high speed railway subgrade deformation disease

A technology for high-speed railway and disease control, applied in the field of geotechnical engineering, can solve problems such as failure to form strength in time, damage to catenary columns on the roadbed, and large slurry diffusion range, so as to ensure the safety of construction and operation, and avoid the subsidence of the roadbed. Harm and effect of controlling the amount of grouting in a single hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

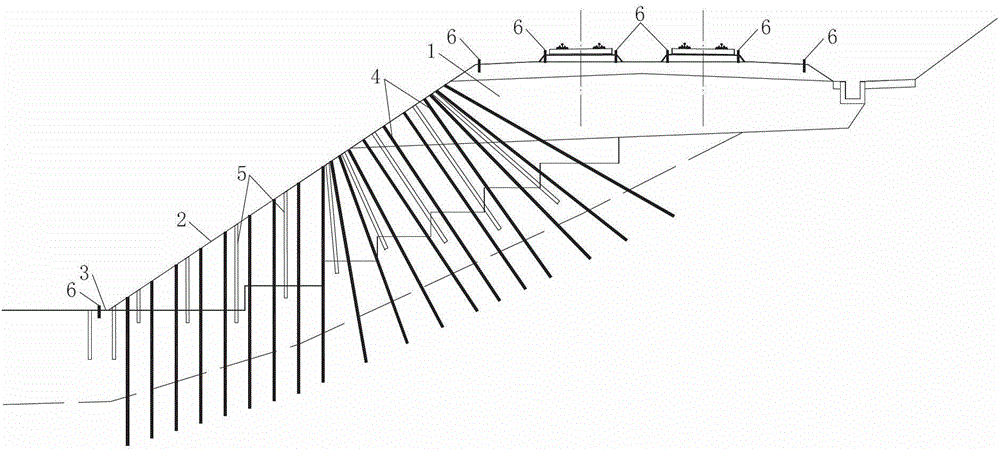

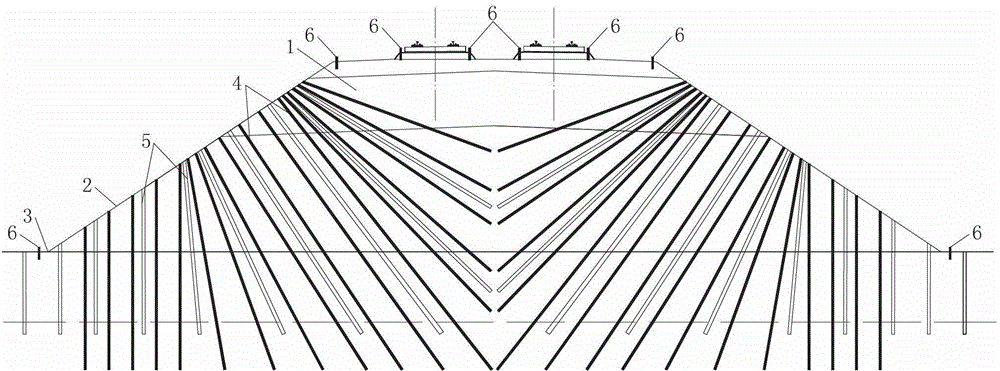

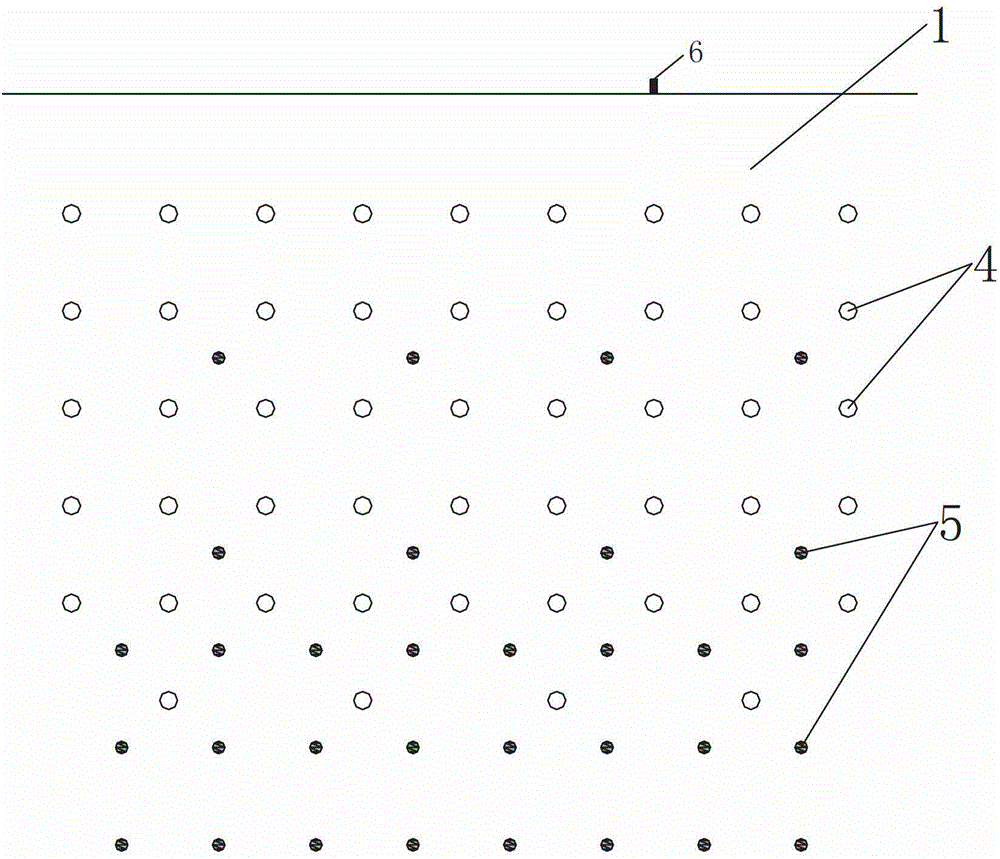

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0038] A micro-disturbance existing high-speed railway subgrade deformation disease treatment method is characterized in that it includes the following steps:

[0039]Step 1: Construct a plurality of micro-piles at intervals both horizontally and vertically on the side slope and slope toe of the existing high-speed railway subgrade to be reinforced, so as to pre-reinforce the existing high-speed railway subgrade; when the existing high-speed railway subgrade is uniformly settled In principle, the micro-piles on both sides of the existing high-speed railway subgrade should be arranged symmetrically. If there is uneven settlement, the piles should be densely distributed at the severely damaged parts; Add appropriate accelerator to M40 cement mortar, so that the strength of the micro-pile is not less than 1MPa 2 hours after the pile is formed. The amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com