Pneumatic hammering demoulding mechanism

A demolding mechanism and a technology of a pneumatic hammer, which are applied in the field of horizontal continuous casting machines, can solve the problems of small stroke of hammer head movement, reduced hammer force, slow hammer head falling back, etc. Reliable, large contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

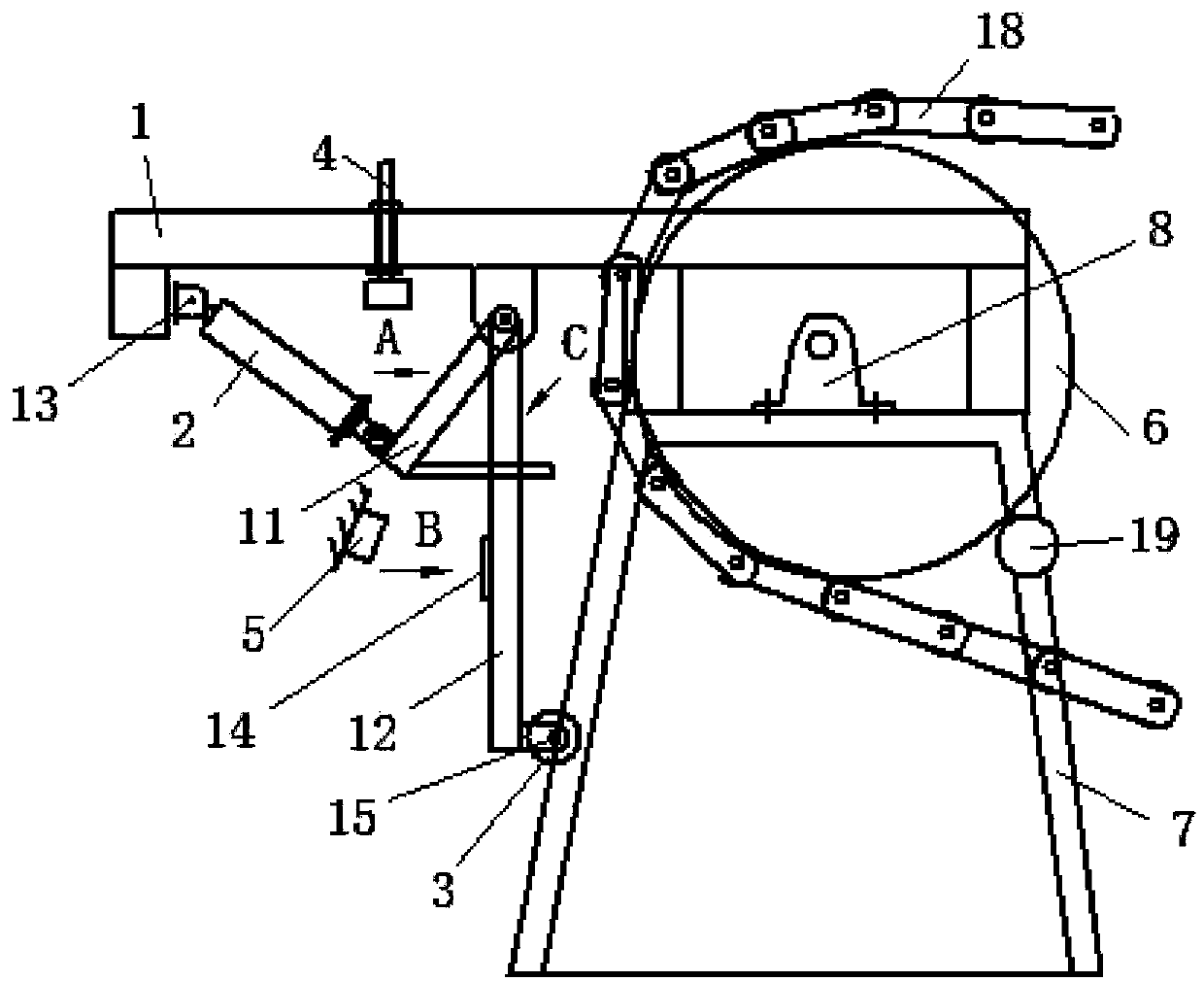

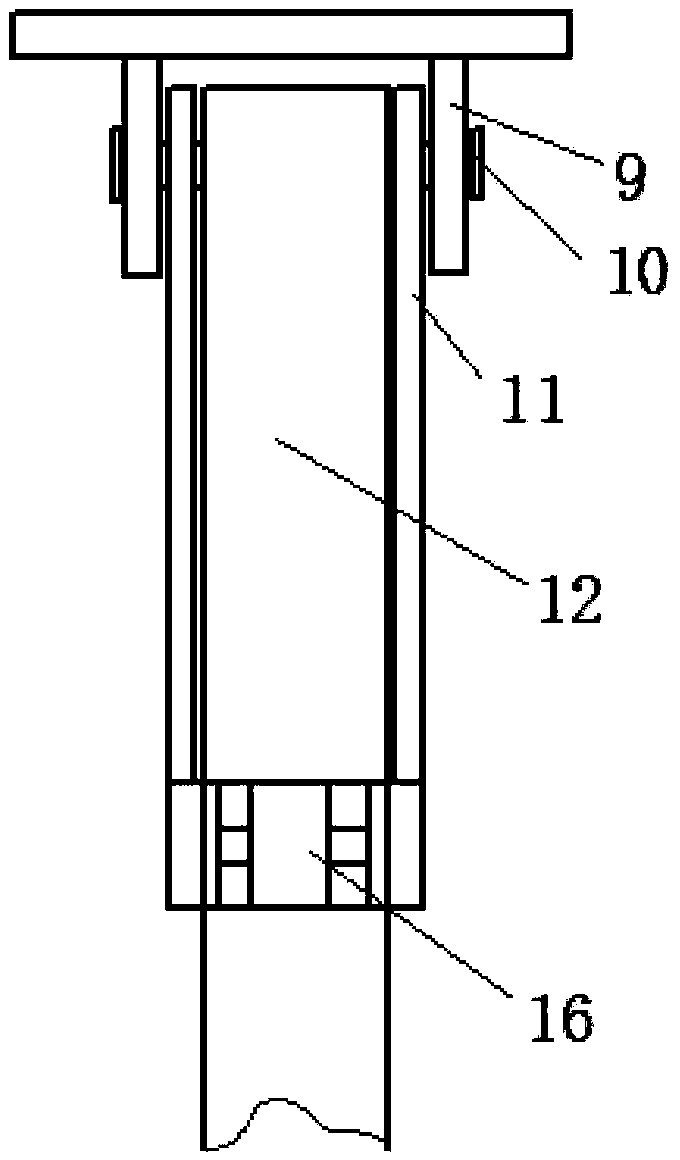

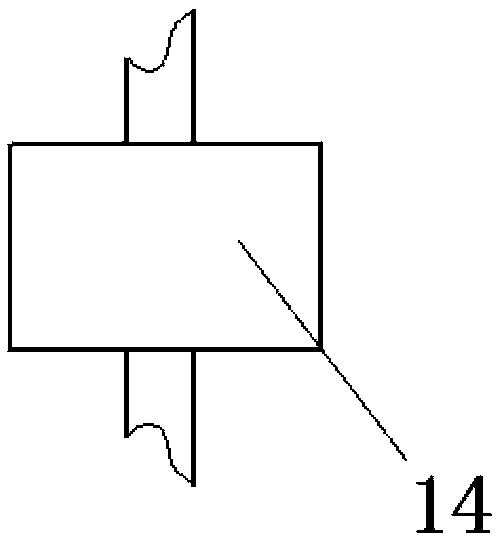

[0023] A pneumatic hammering demoulding mechanism, combined with Figure 1 to Figure 5 , including head support 7, demoulding support 1, cylinder 2, hammer head 3, movable arm 11, hammer handle 12, demoulding support 1 is connected with machine head support 7, and the end of demoulding support 1 is provided with second ear Seat 13, the second ear seat 13 is hingedly connected with the cylinder 2 tailstock, the middle part of the demoulding bracket 1 is provided with the first ear seat 9, the first ear seat 9 is provided with a shaft hole, and the first pin shaft is arranged in the shaft hole 10. The first lug 9 is hingedly connected to one end of the movable arm 11 and the hammer handle 12 respectively through the first pin shaft 10, and the other end of the hammer handle 12 is provided with a second pin shaft 15, and the hammer head 3 is passed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com