Grain drying machine and online moisture detection method thereof

The technology of a grain dryer and a detection method is applied in the direction of storing seeds by drying, material capacitance, etc., which can solve the problem of inability to detect moisture changes on-line, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

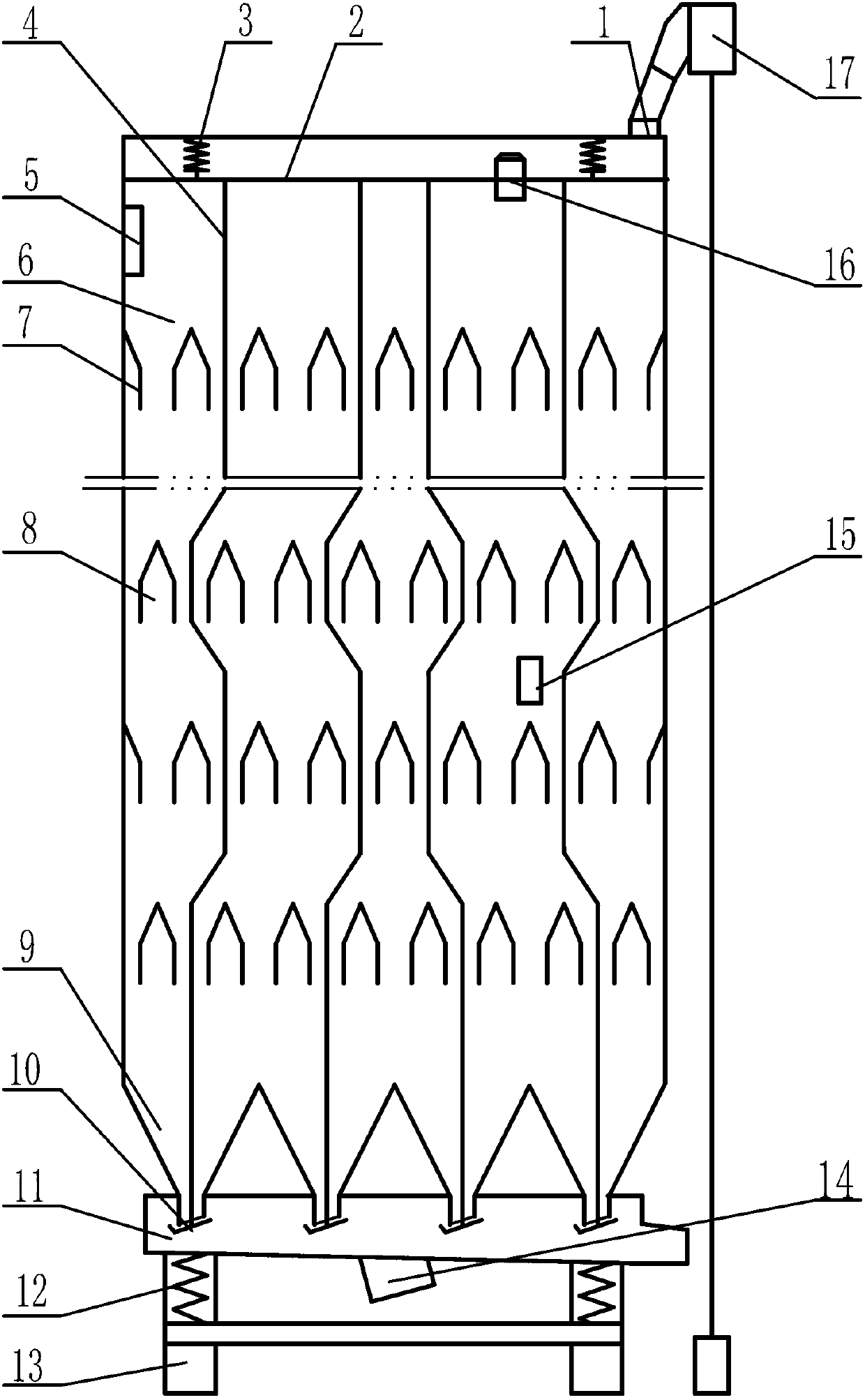

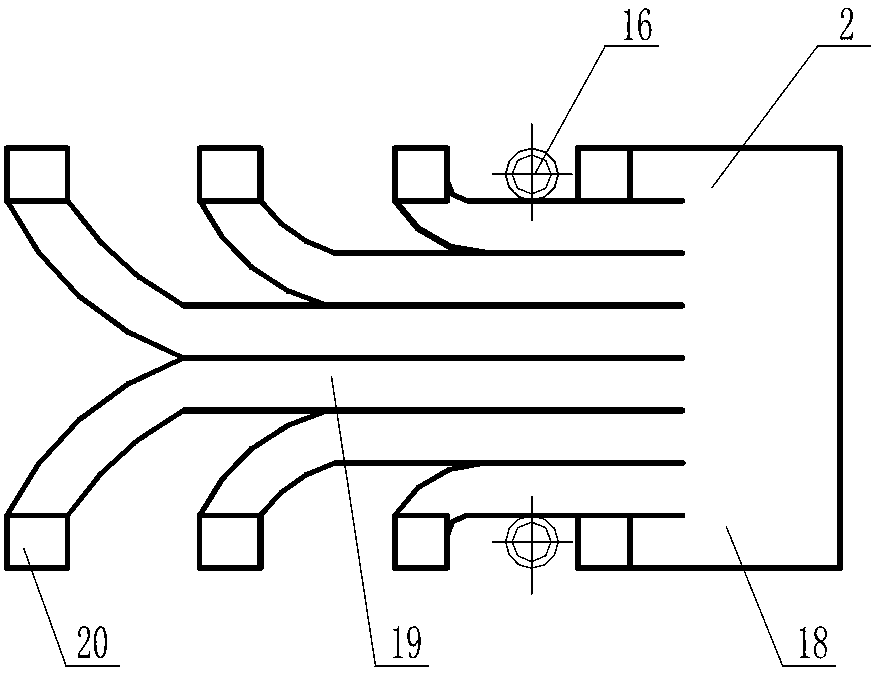

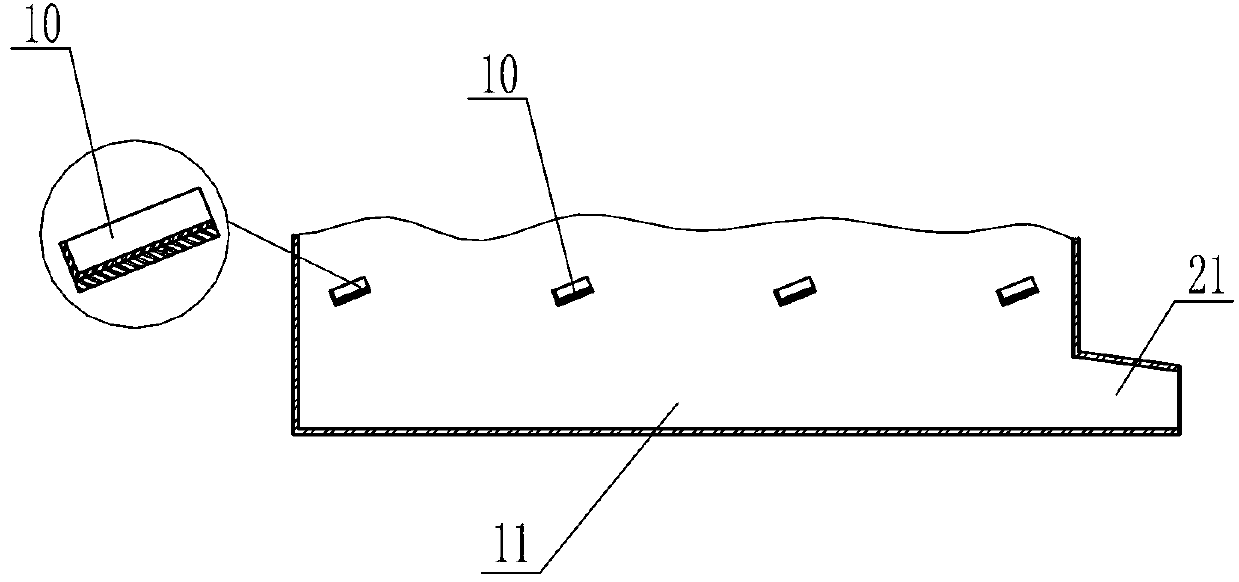

[0038] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ., Install an online moisture detector in the middle of the grain dryer; install a distribution tray (2) and a vibrating motor (16) in the upper part.

[0039] An online moisture detection method adapted to the dryer is set, which includes the following process:

[0040] Such as figure 1 As shown in the figure, the grain is lifted by the hoist and falls from the grain inlet of the dryer to the distribution tray. Under the action of the vibrating motor B, the leveling section of the distribution pan distributes the grain evenly, and the thickness of the grain layer on the leveling section of the distribution pan is controlled to be between 20 and 100mm. The relative error of material layer thickness is less than 10%. The number of distribution channels on the distribution tray is the same as the number of disturbance bars. The end of each distribution channel is provided with a distributing port, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com