Apparatus and method for mixing of corrosive and non-corrosive gas

A mixing device, corrosive technology, used in the field of mixing devices for mixing two or more gases, can solve the problems of wear, expensive lining and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

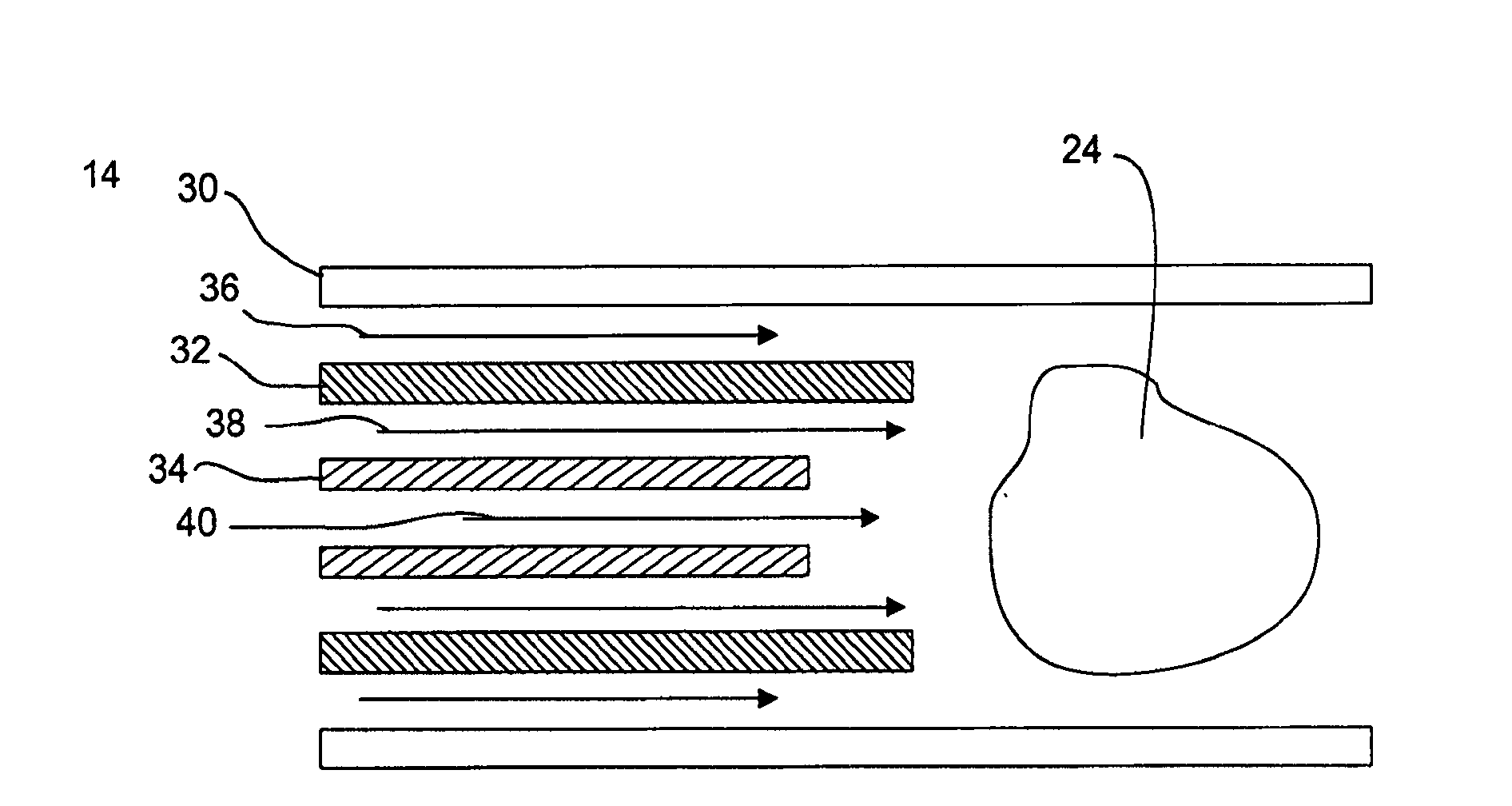

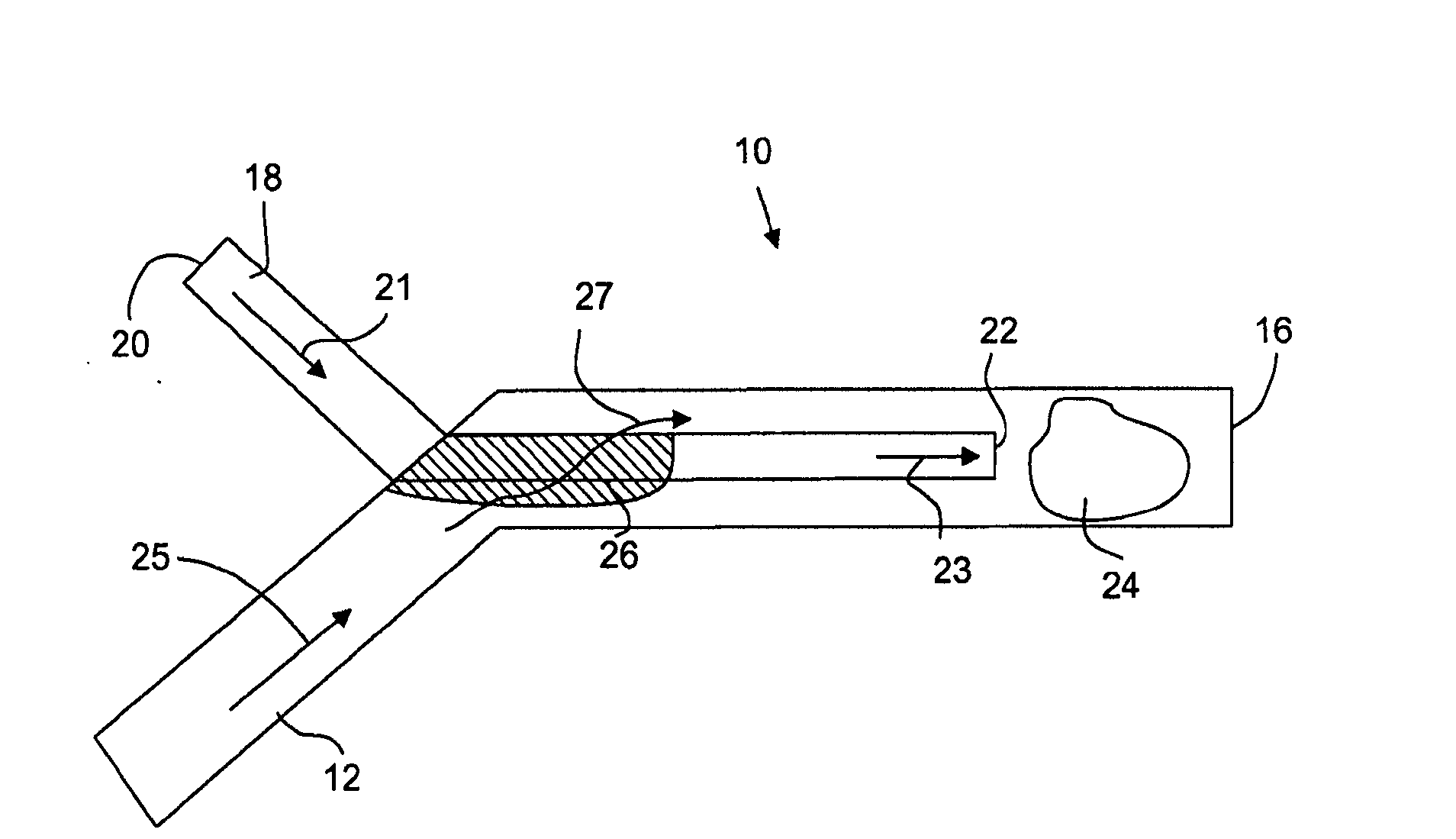

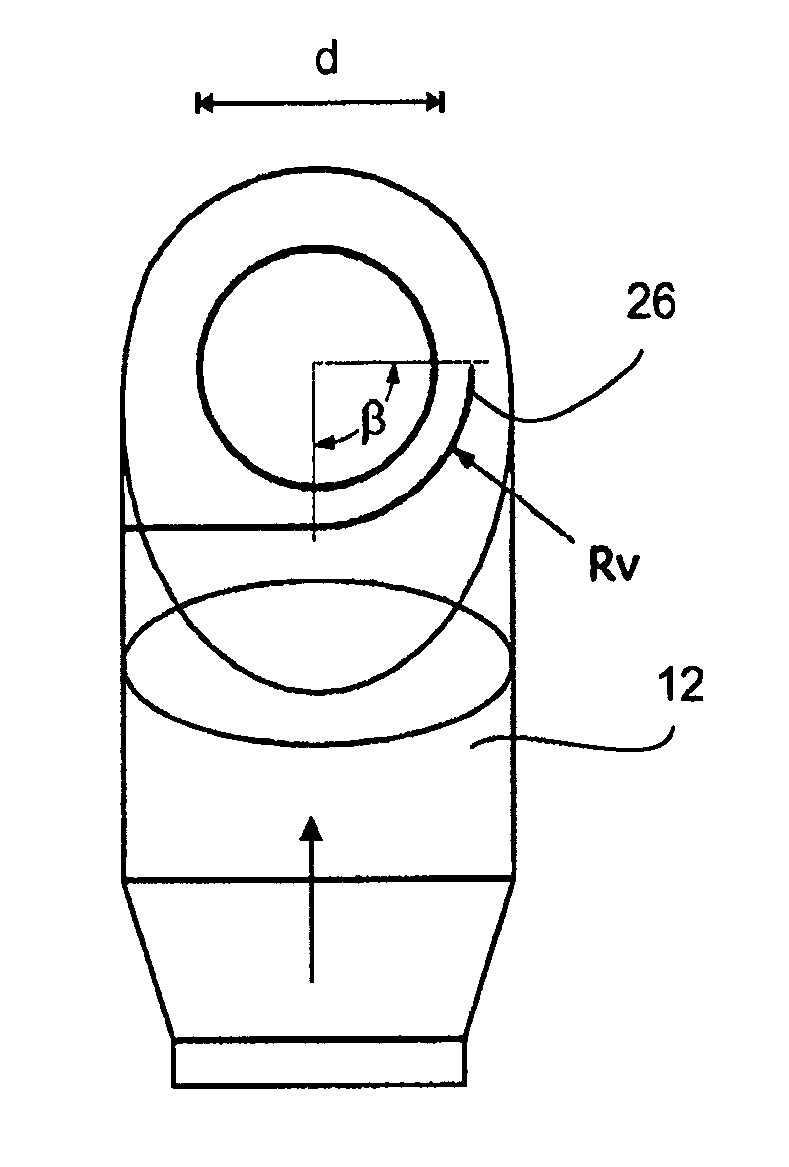

[0031] FIG. 1 schematically shows a mixing device 10 . The mixing device 10 is designed for mixing the first gas with the second gas. In a presently preferred embodiment, the device is used to mix two gases, one of which is corrosive to the mixing device. The mixing device 10 comprises a first gas guiding part 12 having a first gas guiding part inlet 14 and a first gas guiding part outlet 16 . The mixing device 10 also includes a second gas guiding part 18 having a second gas guiding part inlet 20 and a second gas guiding part outlet 22 . The second gas guiding part outlet 22 is arranged in the first gas guiding part 12 so as to mix the first gas and the second gas. A mixing zone is defined in the first gas guiding portion 12 . The mixing zone extends substantially from the area at the outlet 22 of the second gas guiding part. The size of the mixing zone 24 depends on the flow volume and velocity of the gas, and may also depend on the viscosity and temperature of the gas. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com