High-power-factor direct-current current output light-emitting diode (LED) driving circuit with low-energy-storage capacitor

A high power factor, LED-driven technology, applied in the electronic field, can solve problems such as shortened life of electrolytic capacitors, and achieve the effect of improving life and high input power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

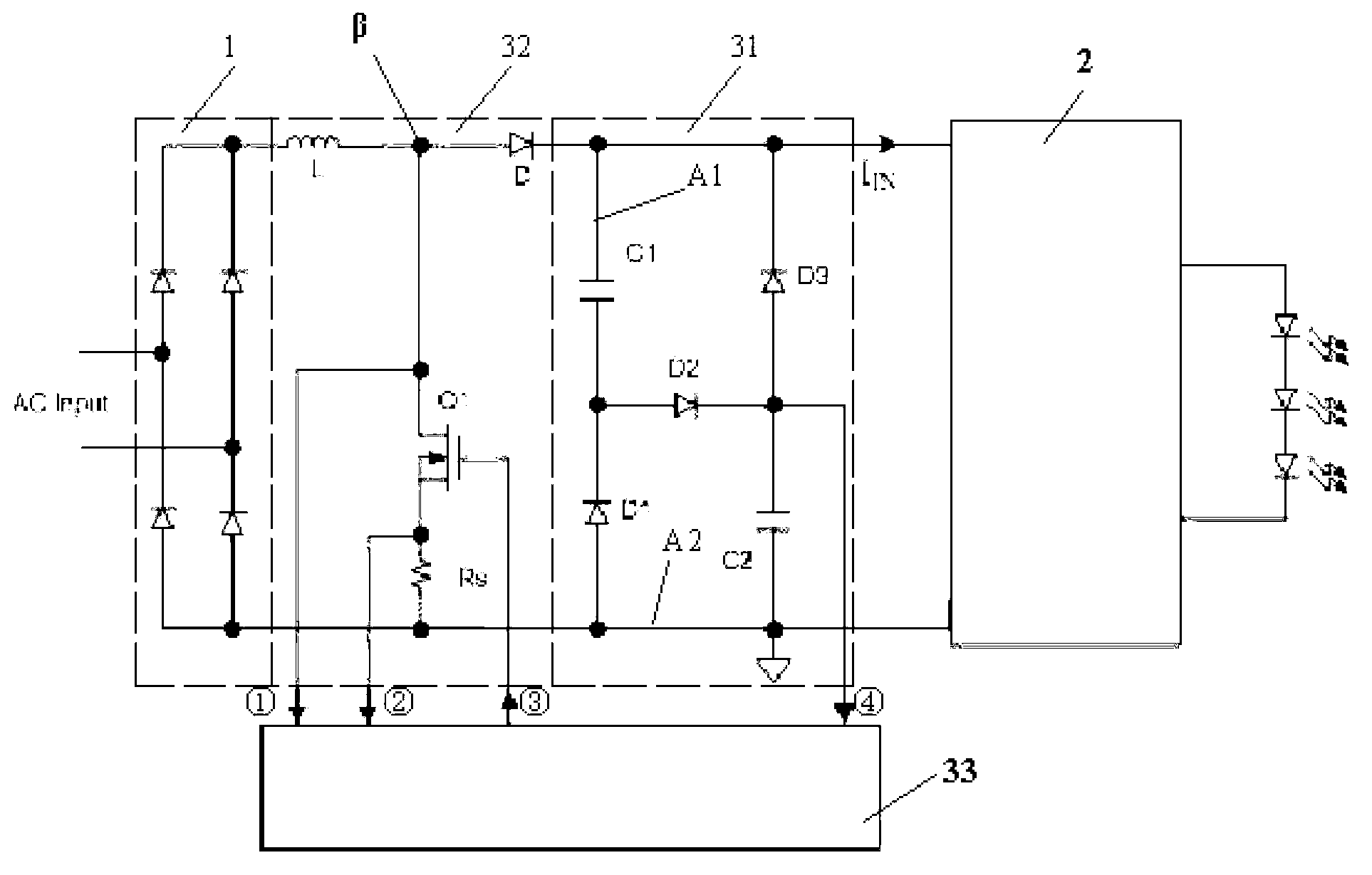

[0061] Embodiment 1, a kind of LED driving circuit of low energy storage capacitance, high power factor direct current output, such as figure 2 Shown: includes a diode rectifier bridge 1, an active nonlinear capacitor network 3 and a subsequent switching power converter 2.

[0062] 1. The diode rectifier bridge 1 is composed of 4 diodes (conventional technology).

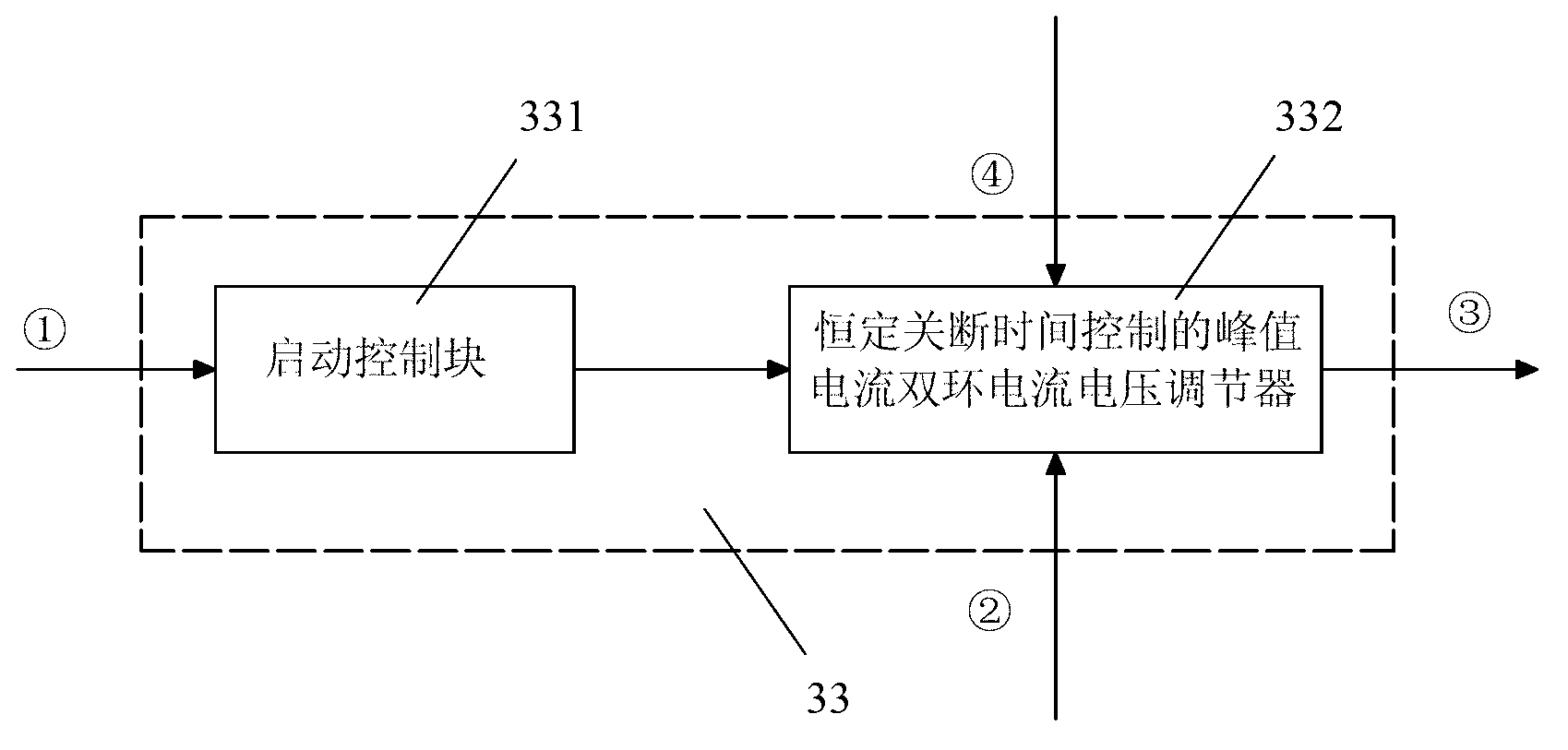

[0063] 2. The active nonlinear capacitor network is specifically composed of a valley filling circuit 31 , a Boost circuit 32 and a module 33 .

[0064] 1) The valley filling circuit 31 is composed of capacitors C1, C2 and diodes D1, D2 and D3.

[0065] Defined as follows:

[0066] The connection A1 between the capacitor C1 and the diode D3 is the positive terminal of the valley filling circuit 31 .

[0067] The connection A2 between the capacitor C2 and the diode D1 is the negative terminal (ie, the ground terminal) of the valley filling circuit 31 .

[0068] The capacitor C1 and the diode D1 form a branch, in...

Embodiment 2

[0090] exist figure 2 Add a diode Din on the basis of Figure 7 shown.

[0091] details as follows:

[0092] like Figure 7 Shown: in figure 2 On the basis of above, a diode Din is added, the anode of the diode Din is connected to the output positive terminal of the diode rectifier bridge 1 , and the cathode of the diode Din is connected to the positive terminal of the valley filling circuit 31 . because Figure 7 Among them, the output end of the diode rectifier bridge 1 has two branches to supply power to the valley filling circuit 31, one is to directly supply power to the valley filling circuit 31 through the diode Din; the other is to supply power to the valley filling circuit 31 through the inductor L, the power switch Q1, and the current detection resistor R S and the diode D form an active boost circuit (ie, Boost boost circuit 32 ) to supply power to the valley filling circuit 31 .

[0093] The corresponding control interval of the LED driving circuit describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com