Method and system for evaluation of man-machine work efficiency of cabin simulation test bed

A manipulation test, ergonomic technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of incomplete comprehensive index system and evaluation standards, design rework manpower, waste of material resources, etc., to achieve a good economy. Sexual and data-invoking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Ergonomic Evaluation System for Automobile Cockpit

[0018] Such as figure 2 As shown, the virtual cockpit hardware system includes an external view screen spliced by multiple LCD screens, which is a display device 1 for simulating the outside view of the cockpit, the front instrument panel is a display device 2 for simulating the instrument panel, and the side console is for The display device 3 of the simulated instrument panel for simulating control of electric rearview mirrors and electric window shakers, the display device 4 of the simulated instrument panel for simulating air-conditioning control, multimedia entertainment terminal and navigation on the central control instrument panel, adjustable position and height The electric seat 5, the steering wheel, clutch, brake, gas pedal, and shift lever adopt real components as the operation panel 6 that is arranged with real buttons / knobs and joysticks, and is used to control the car. The lighting lamp 7...

Embodiment 2

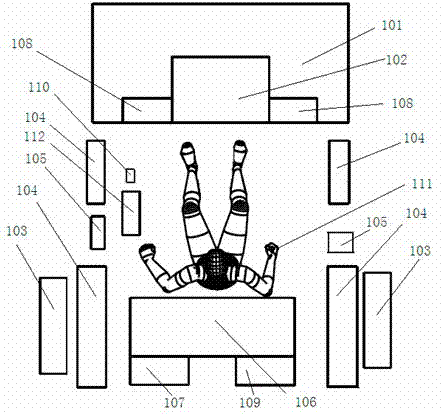

[0022] Example 2: Aircraft cockpit ergonomics evaluation system

[0023] Such as image 3 As shown, the virtual cockpit hardware system includes a display device 101 spliced by multiple liquid crystal display screens to simulate the outside view of the cockpit. The touch screen and the left and right consoles are used to simulate the corresponding position in the aircraft cockpit. The control equipment is the display device 103 of the simulated instrument panel or the operation panel 104 with real buttons / knobs and joysticks; The operation panel 105 of the / knob and the operating lever is arranged on both sides of the driver, and is connected to the aircraft driving simulation system through the sensor, and is used to realize basic flight operations and operations such as missile launching of a fighter plane; the electric seat 106 is arranged in the center of the cockpit, Seats can be adjusted in front, back, and height; lighting 107 is used to simulate the light in the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com