Tunnel self-adaptation cutting system and self-adaptation remote control method for roadheader

A roadheader, self-adaptive technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of harsh working environment, high labor intensity, low excavation efficiency, etc., to improve excavation efficiency, high excavation efficiency, and reduce personnel injury accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

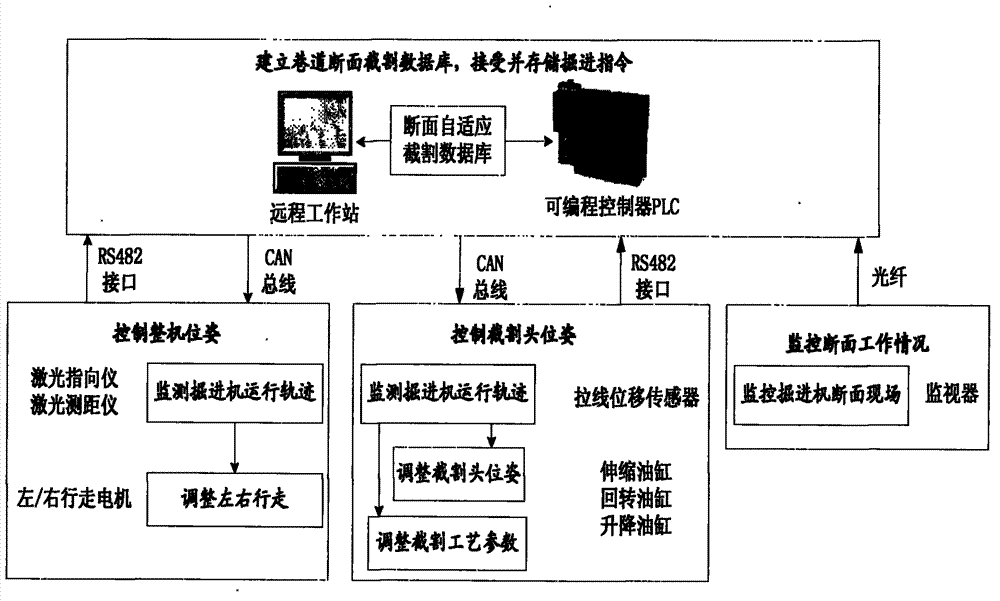

[0043] The section adaptive cutting database of the present invention is constructed on the monitoring system to monitor the state parameters and alarm information of the roadheader in real time, and provide the man-machine interface for setting the roadheading section for the operators. The database development software adopts SQL Server 2008 (server version), and stores the operating state parameters, alarm information and roadway section forming control parameters of the roadheader.

[0044] The specific database construction fields cover:

[0045] (1) Status data: Mainly include the current and voltage signals of the roadheader cutting motor; the roadheader's pose parameters (heading angle, left boundary of the car body, right boundary of the car body); cylinder pressure parameters; cylinder stroke parameters.

[0046] (2) Alarm data: Generate an alarm data table for the overload, short circuit, current leakage, and phase failure of the tunneling machine oil pump motor, cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com