Vacuum detection method and device for abraded surface leakage of slide valves of railway brake

A technology of brakes and slide valve pairs, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve problems such as inapplicable production process control, hidden quality problems, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

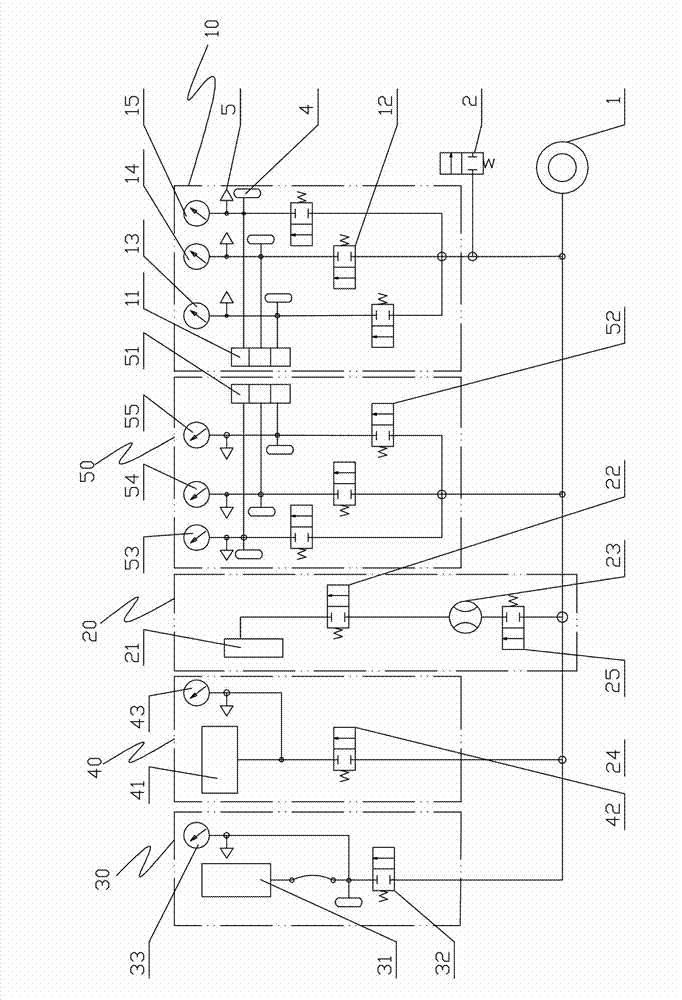

[0022] A method for detecting vacuum leakage on a secondary grinding surface of a slide valve of a railway brake, comprising the following steps:

[0023] 1) Spool valve leakage detection: Fit the grinding surface of the 120 spool valve or 120-1 spool valve to the precision-ground detection seat, and the cavity on the spool valve is divided into three parts: front, middle and rear, and each part of the cavity is connected to the The cavities on the detection seat correspond to each cavity, vacuumize each cavity for 10 seconds, turn off the vacuum pump and keep the pressure for 10 seconds, the leakage of each cavity is not greater than 10KPa;

[0024] 2) Valve sleeve leakage detection: place the main valve body of the 120 valve or 120-1 valve on the test bench, the semi-automatic relief valve faces to the left, put the valve sleeve detection seat into the valve body, turn on the vacuum pump, and vacuum for 5 seconds Finally, turn off the vacuum pump, keep the pressure for 10S, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com