Fine denier three-leaf shaped micro-porous spinneret plate

A technology of spinneret and trilobal shape, which is applied in filament/thread forming, textile and papermaking, fiber processing, etc., and can solve the problem of poor melt flow performance, low production efficiency of ultra-fine denier yarn, and spinneret cooling To improve the flow effect, enhance the spinnability, good hygroscopicity and air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

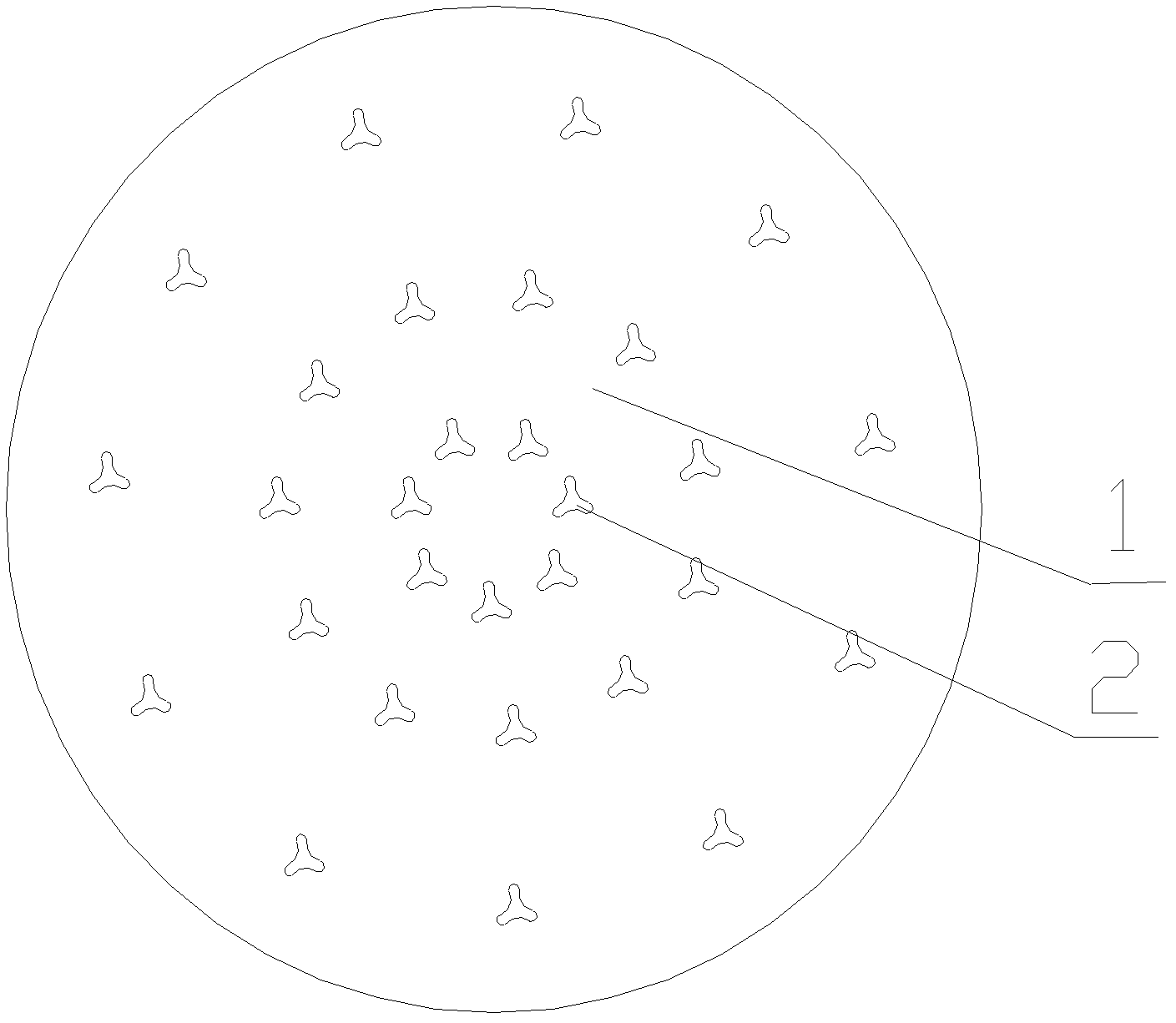

[0019] Such as figure 1 As shown, a fine-denier three-lobe special-shaped microporous spinneret includes a spinneret body 1, and a spinneret hole 2 is arranged on the spinneret body 1. One side of the spinneret hole 2 is a feed inlet, and the other side is a Discharge port, the discharge port of spinning hole 2 is a trilobal micropore, and the interval between adjacent leaves is 120 °. The top of each leaf of the trilobal micropore is a semicircle, and the diameter is the width of the leaf. 0.60-0.85 mm; the two adjacent leaves are arc-shaped, and the radius of the arc is 0.15-0.18 mm; the leaf length of the trefoil microhole, that is, the distance from the center point of the trefoil to the top of the leaf is 0.2-0.23mm .

[0020] The number of spinneret holes of the present invention is 20-36, and a plurality of spinneret holes 2 are arranged in a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com