110 ksi-grade oil sleeve having high resistance to co2 corrosion and its preparation method

A 1.110ksi, manufacturing method technology, applied in casing, drill pipe, earthwork drilling, etc., can solve problems such as low toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition weight percentage of oil casing is: C: 0.06%, Si: 0.4%, Mn: 0.5%, Cr: 12.0%, Ni: 0.9%, Mo: 0.5%, N: 0.03%, the rest is Fe and unavoidable impurity elements. Blooms are smelted and continuously cast into blooms in electric furnaces. Warm ingots are put into the furnace for preliminary rolling, and the surface temperature of the steel ingots in the furnace is less than 600°C. The round billets are annealed after rolling, and the annealing temperature is controlled between 570 and 640°C. The annealing time is controlled within 5 hours, and the annealed tube blank is heated at 1170°C to 1250°C for 1.6 hours and then pierced and hot rolled into a blank tube; ℃, and the tempering time is controlled within 1 hour, so as to obtain 110 steel grade oil casing products.

Embodiment 2

[0031] The composition weight percentage of oil casing is: C: 0.10%, Si: 0.5%, Mn: 0.2%, Cr: 13.1%, Ni: 0.5%, Mo: 0.2%, N: 0.035%, the rest is Fe and unavoidable impurity elements. Blooms are smelted and continuously cast into blooms by electric furnaces. Warm ingots are put into the furnace for preliminary rolling, and the surface temperature of the steel ingots in the furnace is less than 600°C. The round billets are annealed after rolling, and the annealing temperature is controlled between 580 and 600°C. The annealing time is controlled within 6 hours, and the annealed tube blank is heated at 1150°C to 1230°C for 1.8 hours and then pierced and hot rolled into a blank tube; after the hot rolled steel pipe is water quenched at 900 to 980°C, ℃, and the tempering time is controlled within 1 hour, so as to obtain 110 steel grade oil casing products.

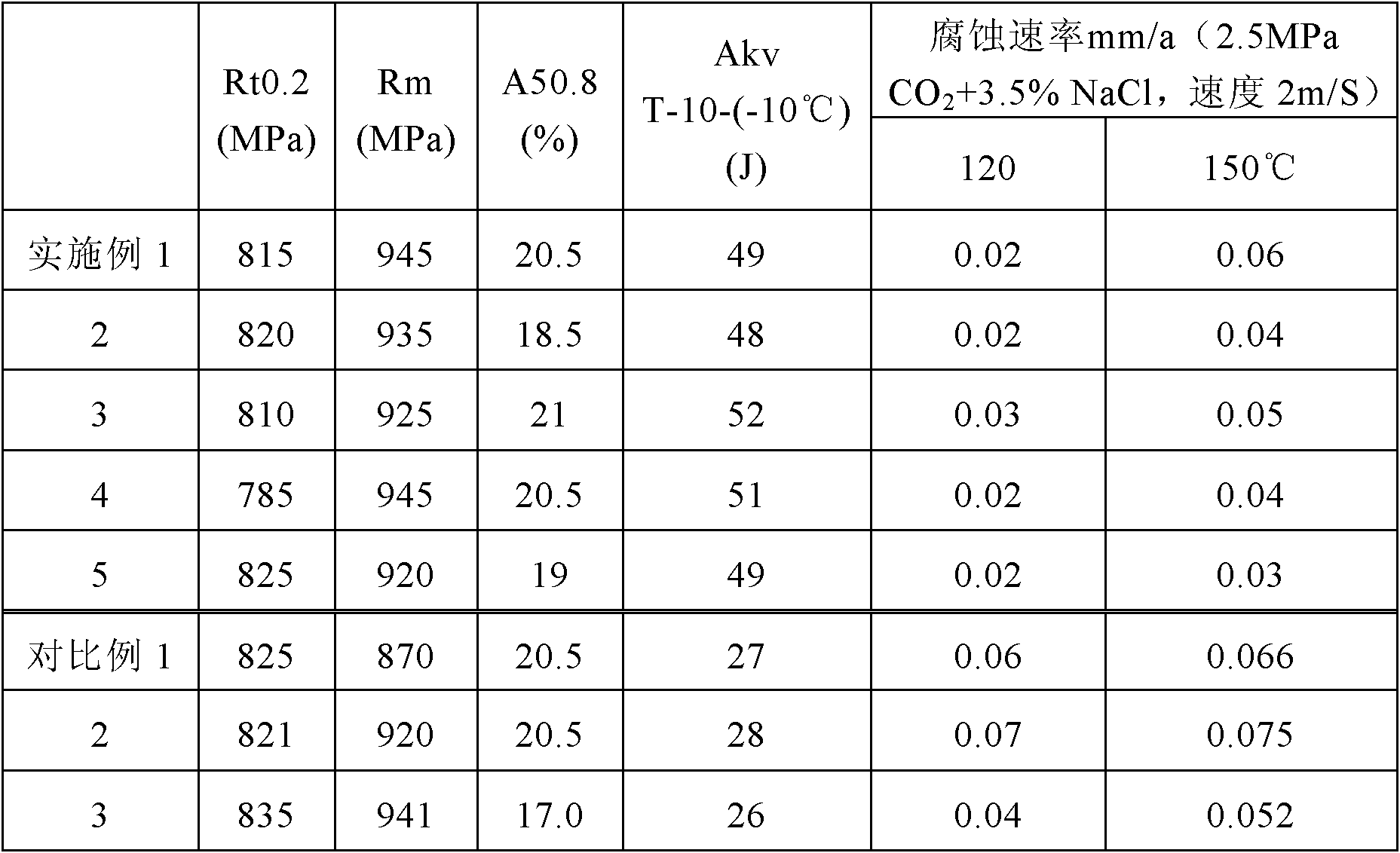

[0032] The chemical composition of other examples is shown in Table 1. The comparative example is Chinese patent 200610028252....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com