Preparation method of Dabigatran etexilate key intermediate

A compound and catalyst technology, applied in the field of chemical synthesis of oral anticoagulant dabigatran etexilate intermediate, to achieve high yield, low price and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

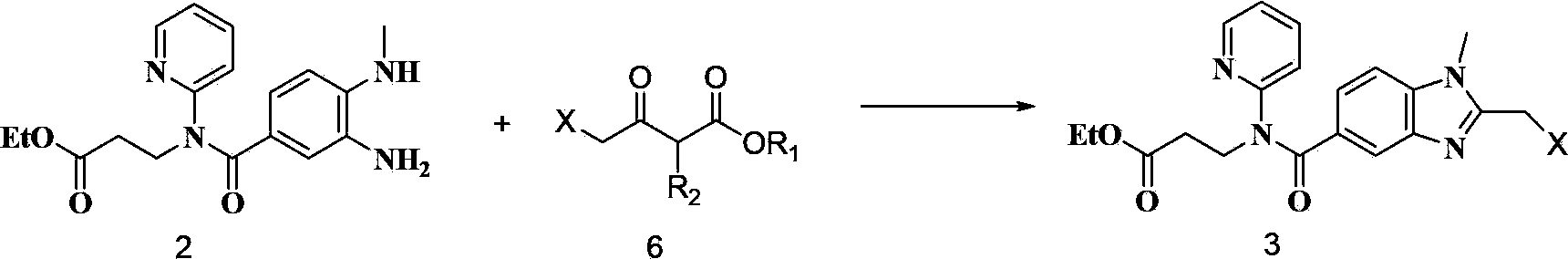

Method used

Image

Examples

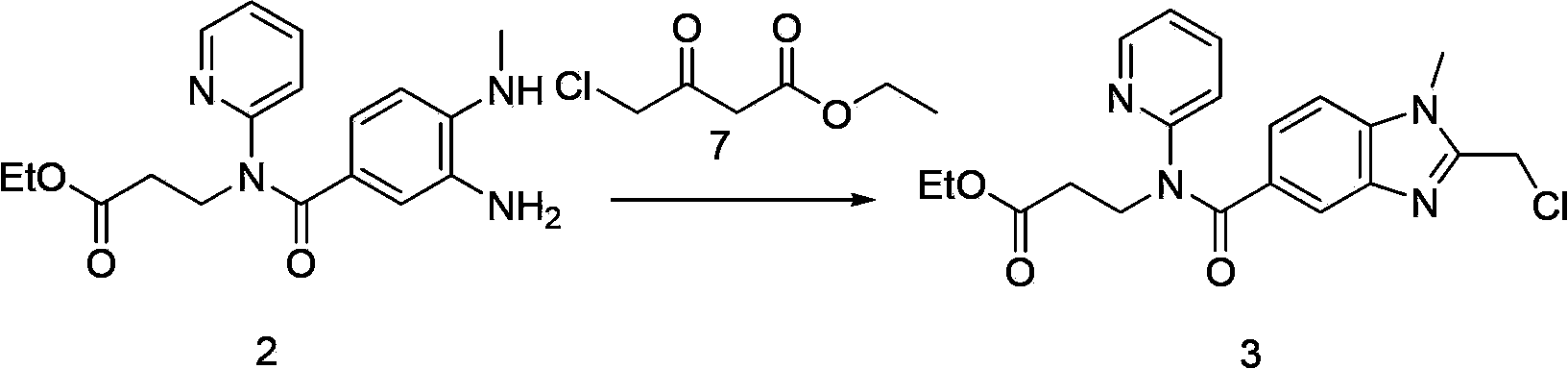

Embodiment 1

[0020]

[0021] Compound 2 (10.0g, 0.029mol) was added to a 250mL three-neck flask, 100mL of ethanol was added, compound 7 (5.3g, 0.032mol), ammonium chloride 1.0g, stirred and reacted at 65-70°C for 2h under nitrogen protection, the solvent was evaporated, and added Ethyl acetate 100mL, wash the organic layer with 100mL×2, wash once with saturated brine, dry over anhydrous sodium sulfate, concentrate to about 50mL, solid precipitates, add 50mL petroleum ether, stir, ice bath for one hour, filter, 50℃ 9.5 g of white solid dried under reduced pressure, yield 81%.

Embodiment 2

[0023] Compound 2 (10.0g, 0.029mol) was added to a 250mL three-necked flask, 100mL of ethanol was added, compound 7 (5.3g, 0.032mol), methanesulfonic acid 1.0g, stirred and reacted at 65-70°C for 2h under nitrogen protection, the solvent was evaporated, added Ethyl acetate 100mL, wash the organic layer with 100mL×2, wash once with saturated brine, dry over anhydrous sodium sulfate, concentrate to about 50mL, solid precipitates, add 50mL petroleum ether, stir, ice bath for one hour, filter, 50℃ 9.8 g of white solid dried under reduced pressure, yield 84%.

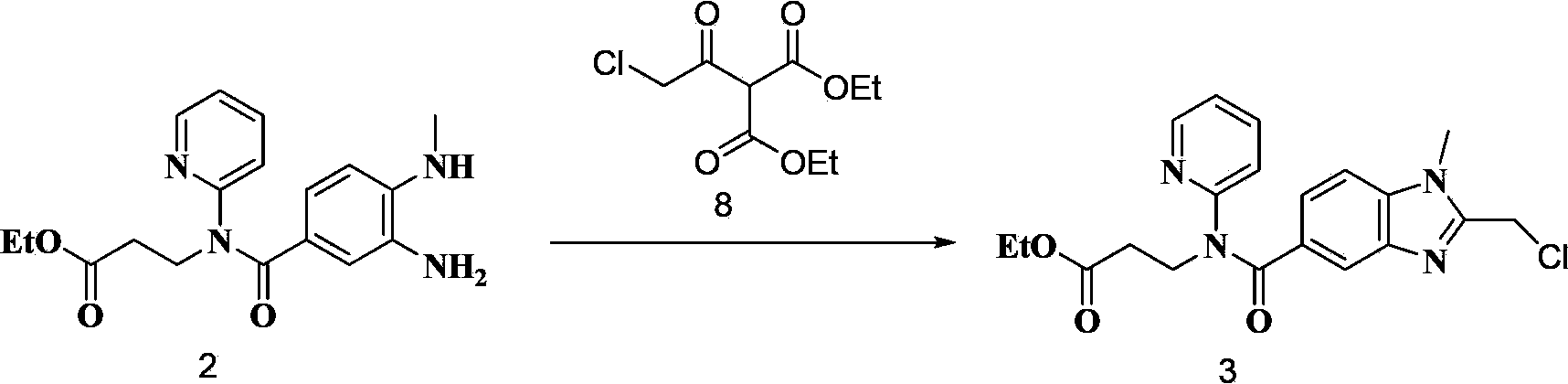

Embodiment 3

[0025]

[0026] Compound 2 (10.0g, 0.029mol) was added to a 250mL three-necked flask, 100mL of ethanol was added, compound 8 (7.6g, 0.032mol), ammonium chloride 1.0g, stirred and reacted at 65-70°C for 2h under nitrogen protection, the solvent was evaporated, and added Ethyl acetate 100mL, wash the organic layer with 100mL×2, wash once with saturated brine, dry over anhydrous sodium sulfate, concentrate to about 50mL, solid precipitates, add 50mL petroleum ether, stir, ice bath for one hour, filter, 50℃ 9.4 g of white solid dried under reduced pressure, yield 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com