Purification method for industrial byproduct salt and purification device therefor

A technology of industrial by-products and purification methods, applied in the direction of alkali metal chlorides, etc., can solve the problems of large use, large heat source consumption, and large energy consumption, and achieve low operating costs, convenient operation and maintenance of equipment, and resource and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

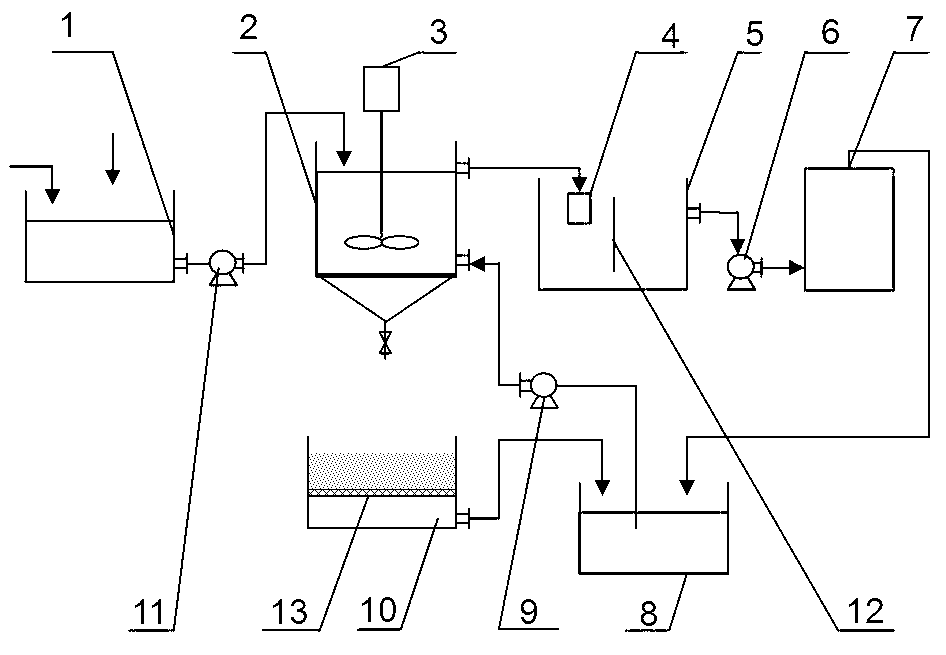

[0043] At normal temperature, add 100kg of solid by-product sodium chloride into the salt tank 1, and then add 60L of saturated sodium chloride aqueous solution into the salt tank 1, stir evenly, and the solution is light yellow.

[0044] The light yellow solution is transported to the washing tank 2 with a slurry pump 11, and a deceleration agitator 3 is installed on the top of the washing tank 2, and the stirring blades of the deceleration agitator 3 extend into the inside of the washing tank 2 to facilitate stirring. Add aqueous sodium hydroxide solution dropwise in the washing tank 2, the mass ratio of sodium hydroxide and water in the aqueous sodium hydroxide solution is 1:2, stir evenly, measure the pH value while adding dropwise, until the pH value is 7, Red oily floating matter appeared above the liquid level in the washing tank 2 and condensed into particles.

[0045]Continuously input pure saturated sodium chloride aqueous solution from the washing liquid inlet on th...

Embodiment 2

[0049] At normal temperature, add 100 kg of solid by-product sodium chloride into the salt tank 1, then add 55 L of saturated sodium chloride aqueous solution into the salt tank 1, stir evenly, and the solution is light yellow.

[0050] Use the slurry pump 11 to transport the light yellow solution to the washing tank 2, and a deceleration agitator 3 is installed on the top of the washing tank 2, and the stirring blades of the deceleration agitator 3 extend into the inside of the washing tank 2 to facilitate stirring. Add dropwise sodium hydroxide aqueous solution in the washing tank 2, the mass ratio of sodium hydroxide and water in the described sodium hydroxide aqueous solution is 3:5, stir evenly, measure the pH value while adding dropwise, until the pH value is 7.5, Red oily floating matter appeared above the liquid level in the washing tank 2 and condensed into particles.

[0051] Continuously input pure saturated sodium chloride aqueous solution from the washing liquid i...

Embodiment 3

[0055] At normal temperature, add 100kg of solid by-product sodium chloride into the salt tank 1, then add 50L of saturated sodium chloride aqueous solution into the salt tank 1, stir evenly, and the solution is light yellow.

[0056] Use the slurry pump 11 to transport the light yellow solution to the washing tank 2, and a deceleration agitator 3 is installed on the top of the washing tank 2, and the stirring blades of the deceleration agitator 3 extend into the inside of the washing tank 2 to facilitate stirring. Add dropwise sodium hydroxide aqueous solution in the washing tank 2, the mass ratio of sodium hydroxide and water in the described sodium hydroxide aqueous solution is 2:5, stir evenly, measure the pH value while adding dropwise, until the pH value is 8, Red oily floating matter appeared above the liquid level in the washing tank 2 and condensed into particles.

[0057] Continuously input pure saturated sodium chloride aqueous solution from the washing liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com