Land airship

A spaceship and tire technology, which is applied in the field of land spacecraft, can solve the problems of large space occupation, bulky size, and inability to adapt to water or sea driving, etc., and achieves the effects of strong applicability, small size, and good manufacturing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 Airship with hydraulic transmission structure

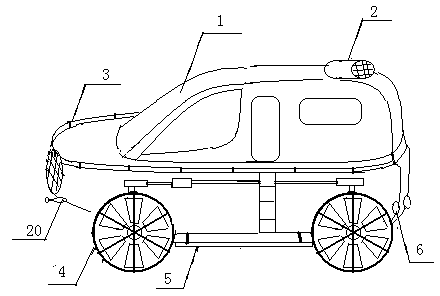

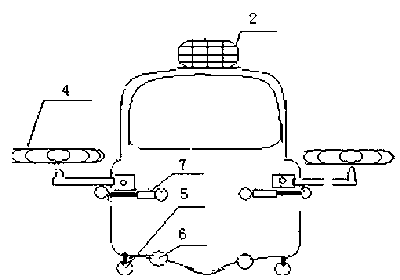

[0022] A land and spaceship of the present invention such as figure 1 , figure 2 , as shown, mainly consists of casing 1, tire 4, railing 3, engine, navigation system, transmission system, control system, automobile assembly, landing gear 5, water wheel drive 6, steering rudder 2, weapon attack system and cab constitute. The landing gear is positioned at the bottom of the casing, the steering rudder 2 is positioned above the rear of the casing, the water wheel driver is positioned at the bottom of the casing rear, and the railing is positioned around the casing. The tires are dual-purpose tires for mobile road walking and flying wheels, such as Figure 7 Shown, tire is made of rubber tire 8, wheel rim 9, adjusting blade 11 and support column 10, and adjusting blade is connected with central axle sleeve 14 through blade connecting hole 12, and support column inserts intermediate axle sleeve. The diameter o...

Embodiment 2

[0024] Embodiment 2 Airship with mechanical transmission structure

[0025] Another embodiment of the present invention is as Figure 5 , Image 6 As shown, it is a land spacecraft with a mechanical transmission structure. Including gearbox 47 , drive shaft 45 , differential 46 , folding shaft 42 , angle adjuster 36 and transfer case 13 , folding shaft 42 and angle adjuster 36 are driven by cone wheel 35 . The engine 32 is connected with the tire 4 through a gearbox 47 , a differential 46 , a transmission shaft 45 , a transfer case 44 and a folding shaft 42 . The engine is connected with the water wheel driver 6 through a transmission shaft 45 and a transfer case 44 . A B brake 43 is provided between the transfer case and the folding shaft. The transmission shaft 10 is connected to the tire 4 via the folding shaft 42 , the angle adjuster 36 and the rotor 21 . A shock-absorbing inner sleeve 40, an angle adjustment sleeve 39 and a fixed plate 38 are arranged between the fold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com