A wall covering with PVC printed on glass fiber base material and its manufacturing method

A glass fiber and manufacturing method technology, applied in the field of wallpaper manufacturing, can solve the problems of poor dimensional stability, short service life, poor flame retardancy, etc., and achieve the effects of high dimensional stability, strong stain resistance and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of manufacture method of glass fiber base material PVC printing wall molding, comprises the following steps:

[0035] (1) According to the formula, the raw materials are polyvinyl chloride paste resin (PVC) 100, diisononyl phthalate (DINP) 70, calcium carbonate 100, stabilizer 3, viscosity reducer 18, titanium dioxide 3, trioxide The ratio of antimony 7 is put into the high-speed disperser and stirred at high speed for about 13 minutes, and then transferred to low-speed stirring for about 10 minutes. While stirring, vacuumize and exhaust, and the mixed PVC paste is pumped into the high-level storage tank through the air pump. . The glass fiber travels on the coating and scraping line, and the PVC paste is evenly coated on the glass fiber substrate at the position of the coating knife by controlling the flow rate of the ball valve. The glass fiber coated with the PVC paste enters the gel roller for heating, becomes a gel state, and cools down. Then enter the 12M ...

Embodiment 2

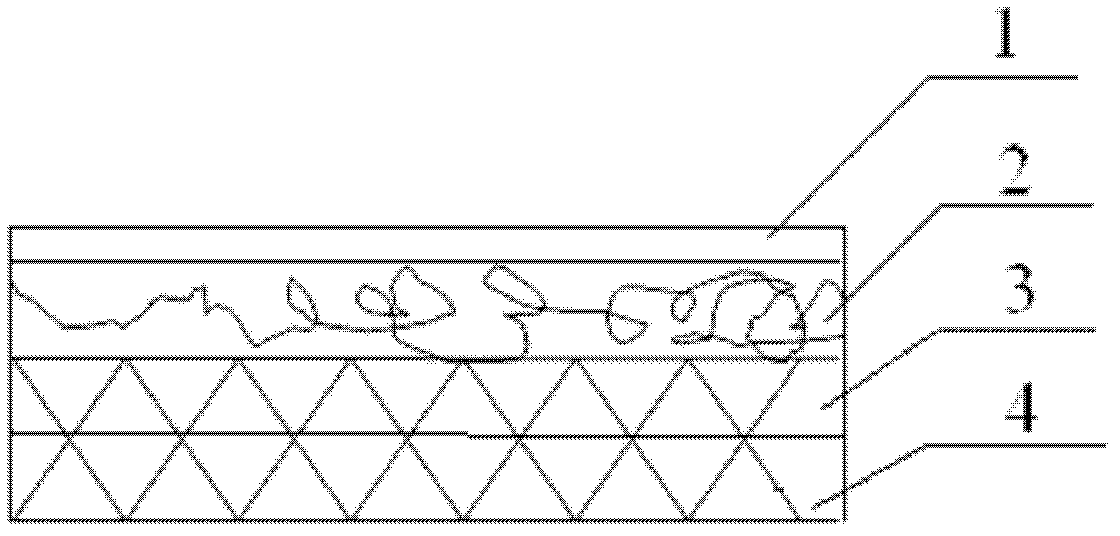

[0041] A kind of glass fiber substrate PVC printing wall plastic, its structure is as follows figure 1 As shown, the wall plastic is composed of a surface UV treatment layer 1, a PVC printing layer 2, a substrate coating layer 3 and a bottom and back composite layer 4 from top to bottom. The surface UV treatment layer 1 is laid on the PVC printing layer 2, and the PVC The printing layer 2, the substrate coating layer 3 and the bottom and back composite layer 4 are connected by hot pressing, the surface UV treatment layer 1 is a polyurethane layer, the thickness of the PVC printing layer 2 is 0.1 mm, and the thickness of the bottom and back composite layer 4 is 1 mm.

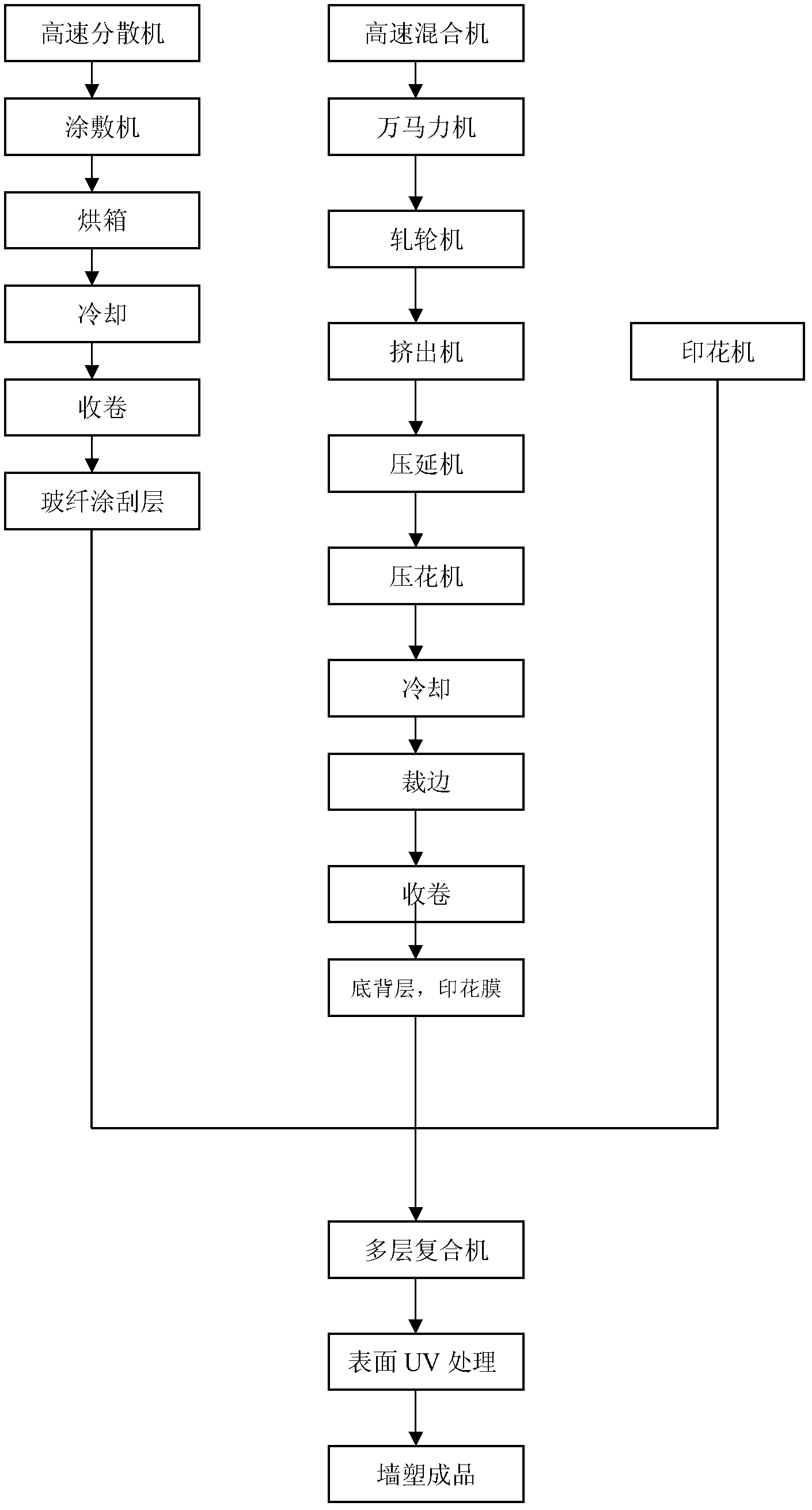

[0042] The manufacture method of glass fiber base material PVC printing wall plastic comprises the following steps, and its technological process is as follows: figure 2 Shown:

[0043] (1) Manufacture of substrate coating and scraping layer

[0044] a. Prepare materials according to the following components a...

Embodiment 3

[0058] A glass fiber substrate PVC printed wall plastic, which is composed of a surface UV treatment layer, a PVC printing layer, a substrate coating layer and a bottom-back composite layer from top to bottom, and the surface UV treatment layer is laid on the PVC printing layer , The PVC printing layer, the substrate coating layer and the bottom and back composite layer are connected by hot pressing, wherein the surface UV treatment layer is a polyurethane layer, the thickness of the PVC printing layer is 0.2mm, and the thickness of the bottom and back composite layer is 4mm.

[0059] The manufacture method of glass fiber substrate PVC printing wall plastic comprises the following steps:

[0060] (1) Manufacture of substrate coating and scraping layer

[0061] a. Prepare materials according to the following components and contents:

[0062] Polyvinyl chloride paste resin (PVC) 100kg, diisononyl phthalate (DINP) 75kg, calcium carbonate 100kg, stabilizer 3kg, viscosity reducer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com