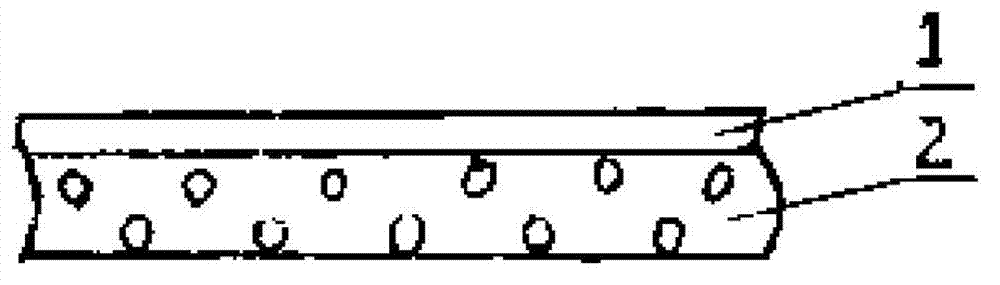

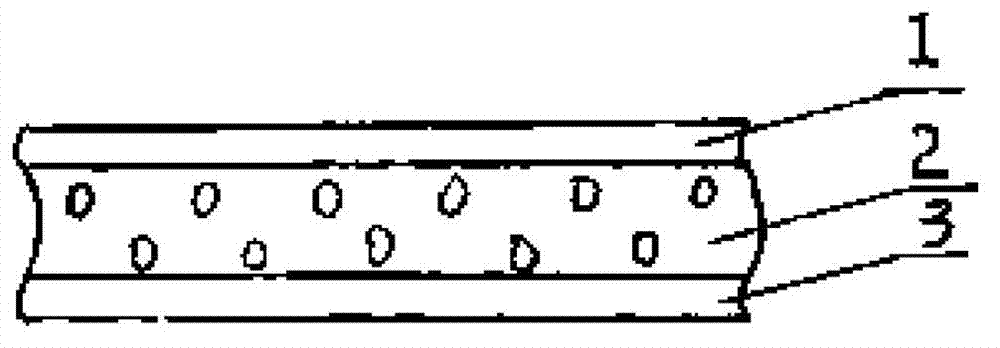

Novel composite aluminum membrane-air bubble film

A technology of bubble film and composite aluminum, which is applied in the direction of lamination device, lamination and layered products, etc., can solve the problems of high cost of composite aluminum film bubble film packaging materials and high price of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] It is made by mixing 75wt% adhesive and 25wt% low-density polyethylene resin particles as the coating layer, and the bubble film and aluminum film are cast at 240°C, the thickness of the aluminum film is 8 microns, and the diameter of the bubble body of the bubble film is is 3 mm.

Embodiment 2

[0020] It is made by mixing 70wt% adhesive and 30wt% low-density polyethylene resin particles as the coating layer. The air bubble film and aluminum film are cast at 260°C. The thickness of the aluminum film is 25 microns, and the diameter of the bubble film is is 30 mm.

Embodiment 3

[0022] It is made by mixing 65wt% adhesive and 35wt% low-density polyethylene resin particles as the coating layer. The bubble film and aluminum film are cast at 280°C. The thickness of the aluminum film is 18 microns, and the diameter of the bubble film is is 12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com