Automatic grinding system for centerless grinding machine

A centerless grinding machine and automatic technology, applied in the direction of grinding machines, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve problems such as inability to effectively improve work efficiency, complex structure, and difficulty in control, and reach the peak Improve the effect, improve product quality, and speed easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

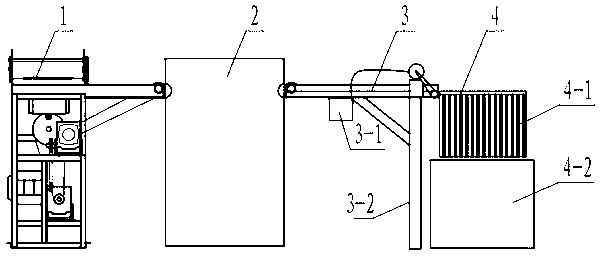

[0026] According to attached figure 1 It can be seen that the present invention specifically relates to an automatic grinding system for a centerless grinder, which belongs to the field of mechanical processing equipment and is an automatic grinding system designed and developed to meet the requirements of a centerless grinder.

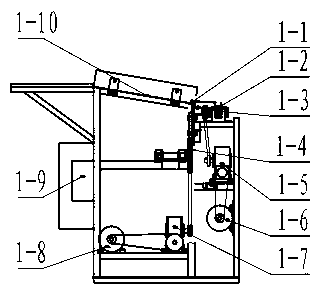

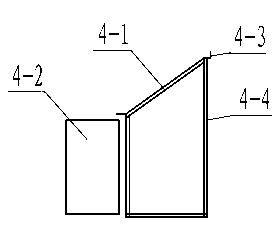

[0027] The automatic grinding system in the present invention includes a centerless grinder 2, the feed port of the centerless grinder 2 is provided with a feed system 1, and the outlet of the centerless grinder 2 is provided with a discharge system 3, and the end of the discharge system 3 There is a receiving device 4 at the end. as attached figure 2 As shown, the feeding system 1 includes a jacking device, a feeding device and a feeding rack 1-10, wherein the feeding rack 1-10 has two parts, one part is a horizontal platform for preventing bar materials, and the other part is The inclined slideway can be that the bar material slides slowly under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com