Extraction head for solid phase micro-extraction, and preparation method and applications of extraction head

An extraction head and extraction technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as poor stability and specificity, matrix and environmental interference, and short service life, and achieve good stability and improved The effect of mechanical strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

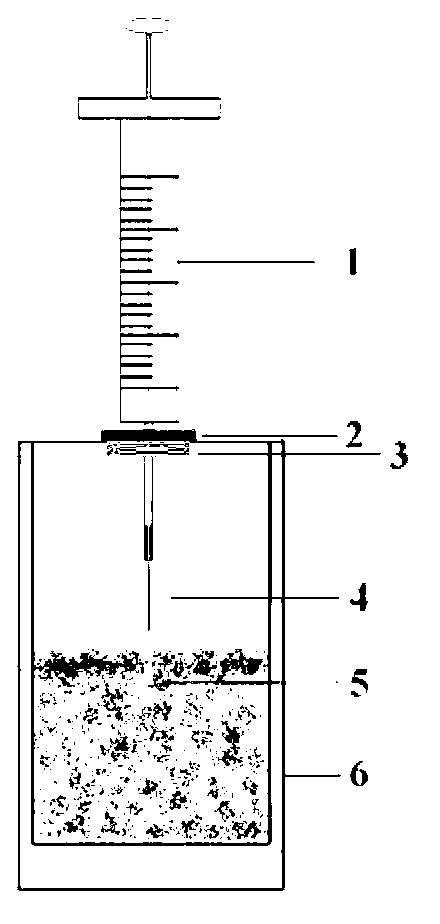

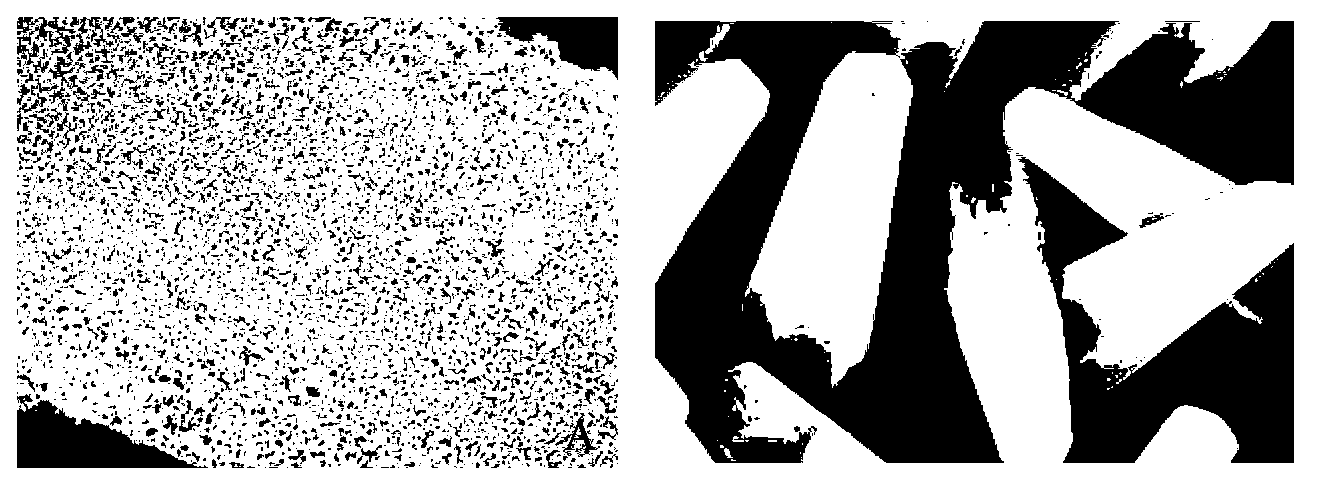

[0040] Example 1: ZnO nanorod coatings were directly prepared on modified stainless steel wire substrates by hydrothermal synthesis. Before the preparation, the stainless steel substrate was ultrasonically cleaned with acetone and water for 5 min, and then dried naturally at room temperature. Prepare zinc oxide reaction solution: add 20mL deionized water to a 25mL reaction bottle, then add equimolar zinc nitrate hexahydrate and hexamethylenetetramine to the solution to obtain 0.025mol L -1 The reaction solution was homogeneously mixed by ultrasonication. Pass the cleaned stainless steel substrate through the self-made foam bottle cap, and directly immerse it vertically in the reaction solution. Leave about 1 cm of stainless steel wire in the reaction bottle to grow the coating, and seal the reaction bottle. The reaction vial was placed in an oven at 90 °C for 4 h. After the reaction was completed, the stainless steel wire fiber was taken out, and the zinc oxide nanorod layer...

Embodiment 2

[0041] Example 2: The following is a comparison of the extraction efficiency of the zinc oxide nanorod coating prepared by the present invention for 5 kinds of aldehyde compounds with that of a commercial extraction head. Depend on image 3 It can be seen that for most of the target aldehydes, the ZnO nano-coating has comparable extraction efficiency to the commercial coating. The thickness of the zinc oxide nano-coating is only 5 μm, while the thickness of the commercial coating is 85 μm. Since zinc oxide nanorods have a large specific surface area and a certain polar surface, it has a high extraction efficiency for volatile aldehydes. This more regular arrangement of ZnO nanorods increases the effective surface area and thus increases the extraction sites of the fibers accordingly. This solid-phase microextraction method based on zinc oxide nanorod coating has a good extraction effect for aldehydes produced by oxidation in complex food matrices.

[0042] GC / FID operating ...

Embodiment 3

[0043] Example 3: The detection results of target aldehydes in three actual instant noodle samples by the solid-phase microextraction-gas chromatography method based on zinc oxide nanorod coating established in the present invention are given below. Table 1 shows that this method can detect the target aldehyde compounds in instant noodle samples, and has a good recovery rate, the recovery rate ranges from 70.5% to 129.4%.

[0044] Table 1

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com