Veridical lifting type monomer copying cotton topping machine

A technology of vertical lifting and topping machine, applied in agricultural machinery and implements, cutting tools, cutting equipment and other directions, can solve the problems of high topping failure rate, complex structure, and inability to realize the immediate profiling of the top of a single cotton plant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

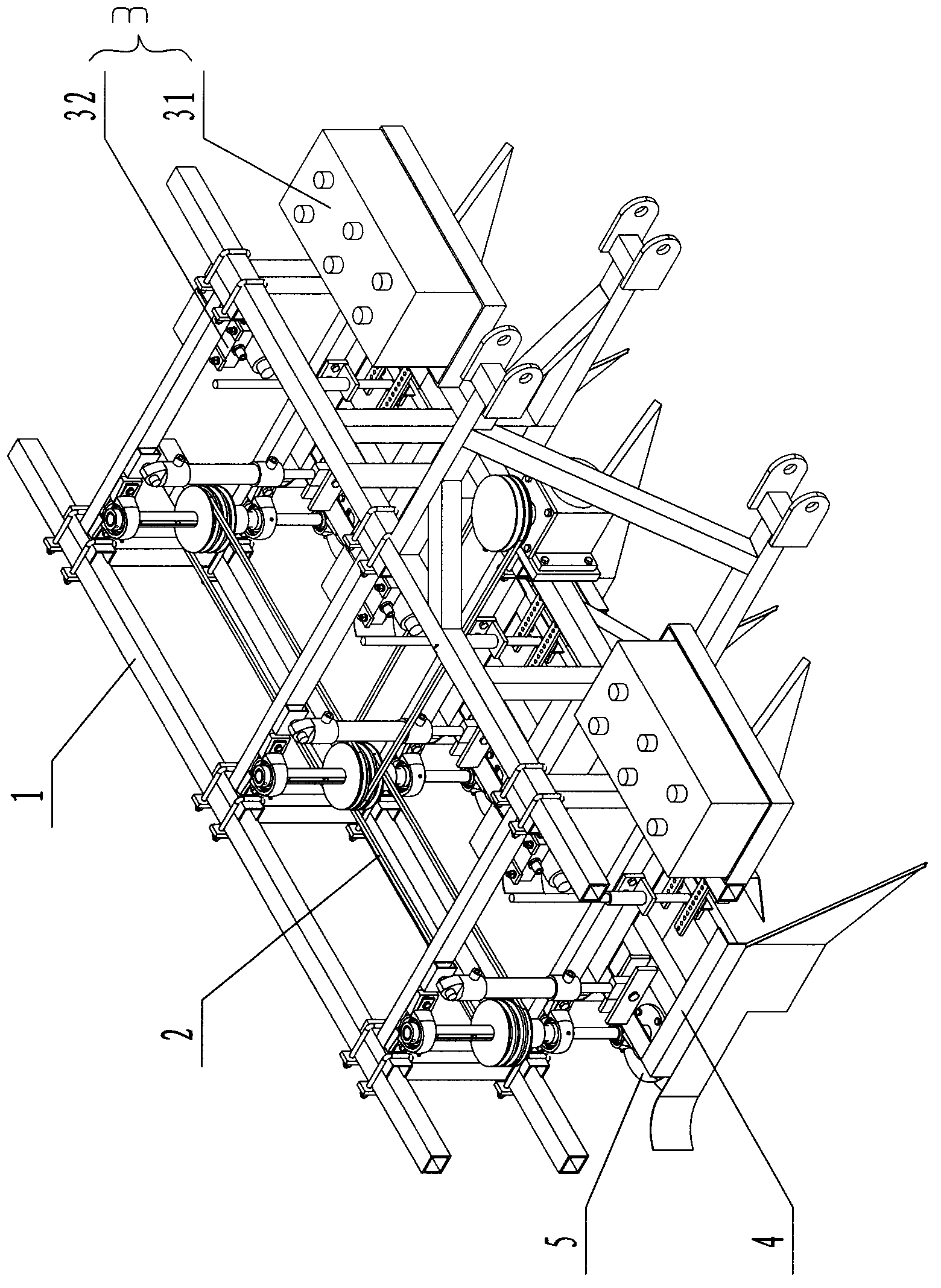

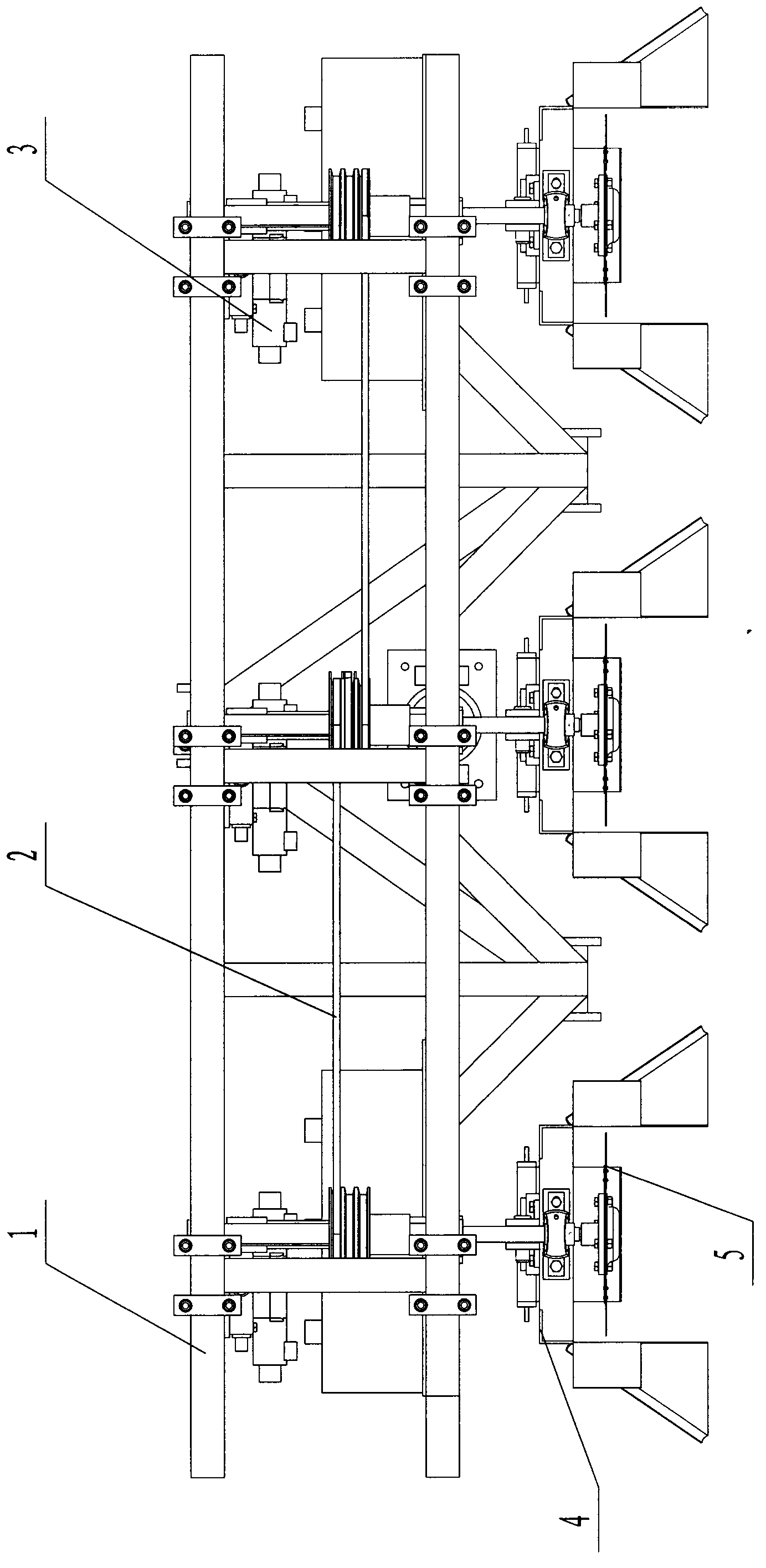

[0023] refer to Figure 1~6 , is a schematic diagram of the mechanism of the patent of the present invention, including a combined frame 1, a transmission system 2, an electrical system 3, a profiling platform 4, and a topping device 5 (such as figure 1 Shown,) the transmission system 2 (such as figure 2 shown) is fixed inside the combined frame 1, and the transmission system includes a sleeve transmission 21, a belt 22, a fixed bearing 23, a lifting cylinder 24, a large pulley 25, a speed changer 26, and an intermediate pulley 27. During the working process, the power is transmitted to the large pulley 25 by the transmission 26, and the large pulley is transmitted to the middle pulley 27 through the belt, and the middle pulley distributes the power to the pulleys on both sides, so as to ensure the rotation of the sleeve transmission Power; the sleeve transmission 21 (such as Figure 4 ) includes a drive sleeve 211 with a guide groove, a pulley 212, a cutter shaft mechanism...

Embodiment 2

[0027] Compared with Embodiment 1, the difference of this embodiment is that the sleeve transmission device can be designed as a spline sleeve-spline shaft transmission device, wherein the spline shaft is the topping tool shaft, and the spline sleeve and spline The cooperation of the key shaft completes the transmission of rotational power and ensures the guidance of the topper cutter shaft and the vertical lift of the profiling platform.

Embodiment 3

[0029] refer to Figure 7 , a schematic diagram of the mechanism of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of Embodiment 3 is that the profiling device in the movable profiling device 43 is a roller profiling device 435 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com