Apparatus and process for cohesive joining

A technology of material locking and aluminum materials, applied in the direction of connection, welding equipment, welding equipment, etc., can solve the problems such as connection improvement cannot be known, and achieve high processing reliability, high connection strength, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

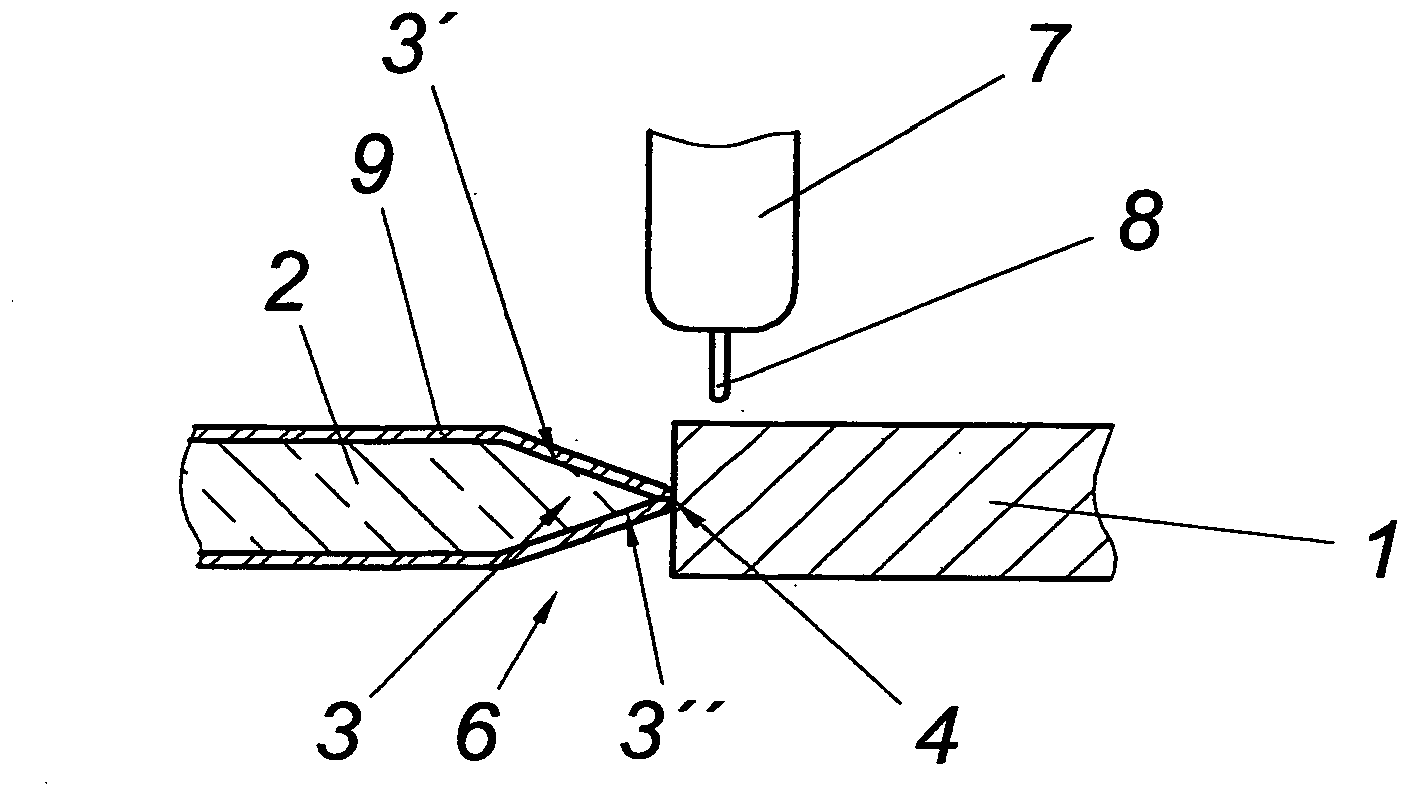

[0028] according to figure 1 A known method for joining together two sheets 1 and 2 with different melting points in a cohesive manner is shown. The end plate 1 therefore has an aluminum material or an aluminum alloy and the connecting plate 2 has a steel material. It is known to provide on the connecting sheet 2 a cut joint edge 3 which forms joint surfaces 3 ′ and 3 ″ which are inclined towards each other, that is to say a V-shaped end. The joint edge 3 hits the end sheet 1 , Rather, it hits the blunt joining edge 4 of the end sheet metal. When the contacting sheets 1 and 2 are spliced together, the additional material 5 is now used (additional material 5 is Image 6 only schematically shown in ), wherein the quality in the splicing area 6 after the brazing method is improved, additional material is introduced into this splicing area 6 , which is achieved by the welding device 7 . This welding device 7 is now in the figure 1A cohesive connection is established between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com