High-power narrow-linewidth 1.94mum Tm: YLF (Yttrium Lithium Fluoride) laser

A technology with narrow line width and high power, applied in the structure/shape of optical resonators, etc., can solve problems such as difficult to achieve high-power laser output, and achieve the effect of compact structure, good stability, and narrow line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

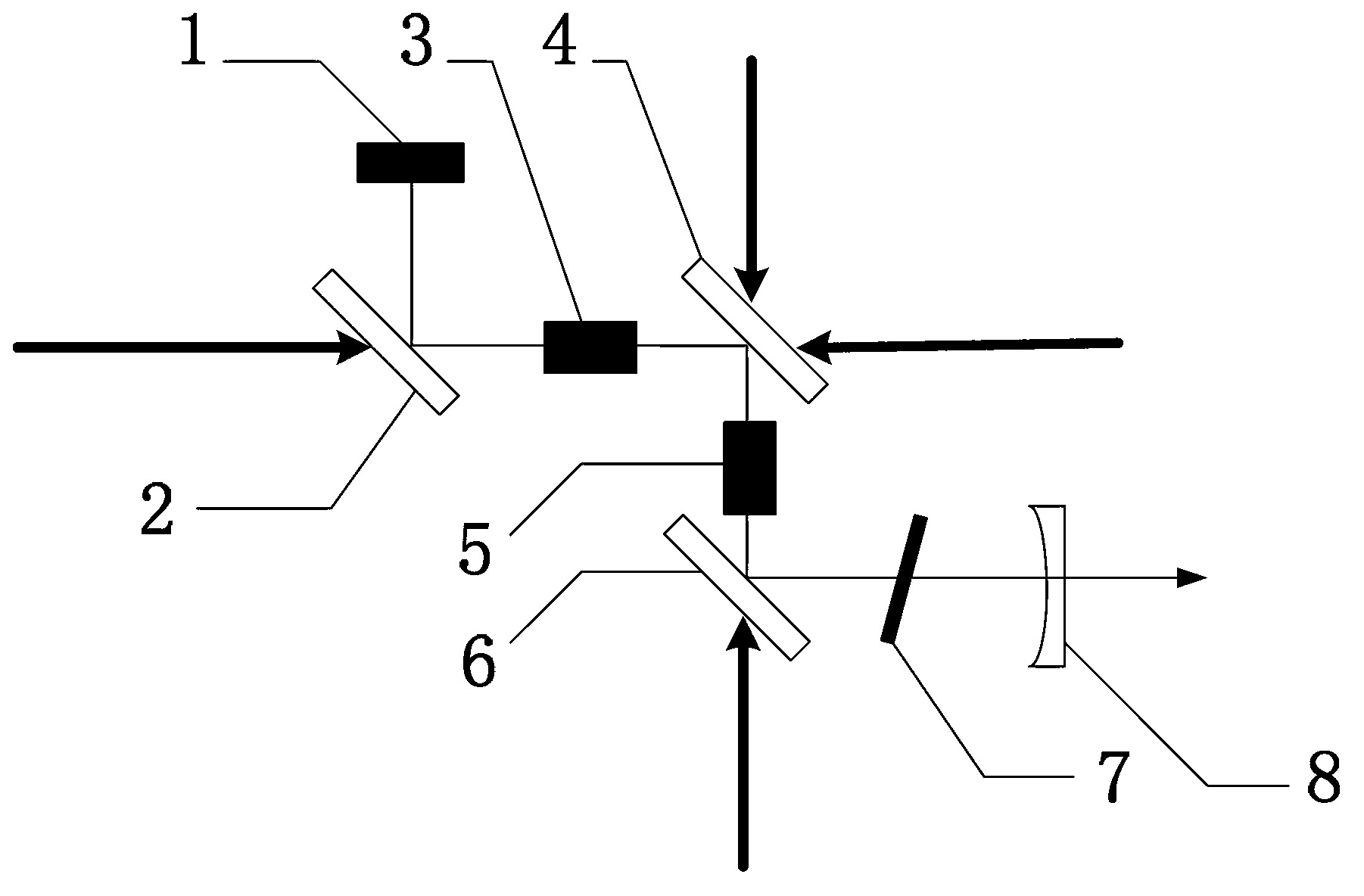

[0014] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, the 1.94 μm Tm:YLF laser device of high power narrow linewidth, it comprises volume grating 1, No. 1 total reflection mirror 2, No. 2 total reflection mirror 4, No. 3 total reflection mirror 6, No. 1 Tm:YLF Laser crystal 3, No. 2 Tm:YLF laser crystal 5, F-P etalon 7 and 1.94μm laser output coupling mirror 8;

[0015] The No. 1 pump light incident on the system is transmitted by the No. 1 total reflection mirror 2 and then enters the No. 1 Tm:YLF laser crystal 3. After being absorbed by the No. 1 Tm:YLF laser crystal 3, 1.94 μm laser radiation is generated, and the 1.94 μm laser is incident on the No. two total reflection mirror 4 obtains reflected light through No. two total reflection mirror 4 reflections, and described reflection light is incident to No. two Tm:YLF laser crystal 5, after No. two Tm:YLF laser crystal 5 transmits and is incident to No. three full reflection mirror ...

specific Embodiment approach 2

[0024] Embodiment 2. The difference between this embodiment and the high-power narrow-linewidth 1.94 μm Tm:YLF laser described in Embodiment 1 is that the volume grating 1 is coated with a 1.94 μm high-transparency film.

specific Embodiment approach 3

[0025] Embodiment 3. The difference between this embodiment and the high-power narrow linewidth 1.94 μm Tm:YLF laser described in Embodiment 1 is that the reflection wavelength of the volume grating 1 is 1940 nm, and the full width at half maximum of the reflection spectrum is less than 1 nm. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com