Nearly singular configuration wide-range parallel six-dimensional force sensor

A six-dimensional force sensor, a large-range technology, applied in the field of six-dimensional force sensors, can solve the problems of reduced sensitivity, decreased measurement characteristics, complexity, etc., and achieves the effects of improved sensitivity, high sensitivity, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

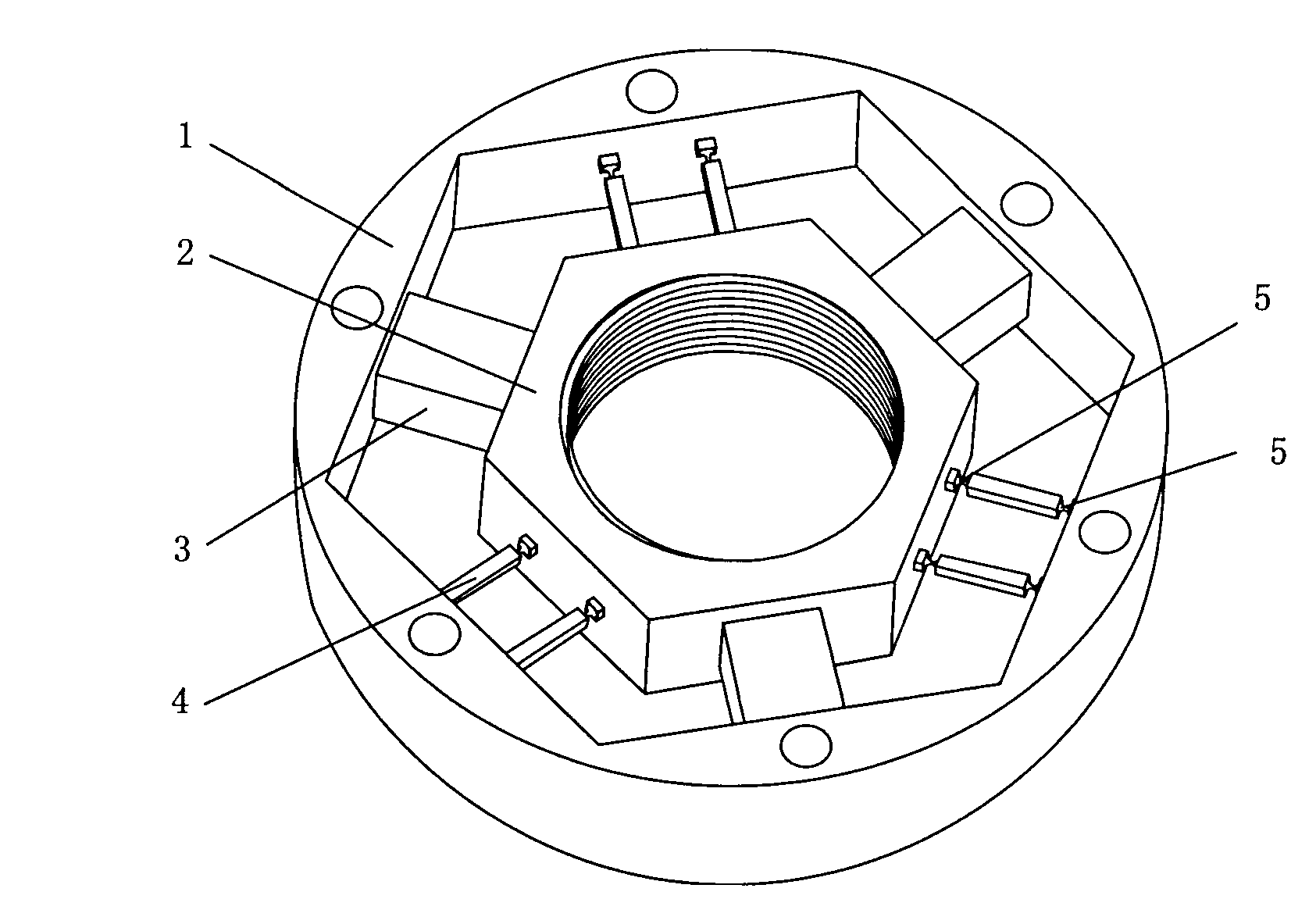

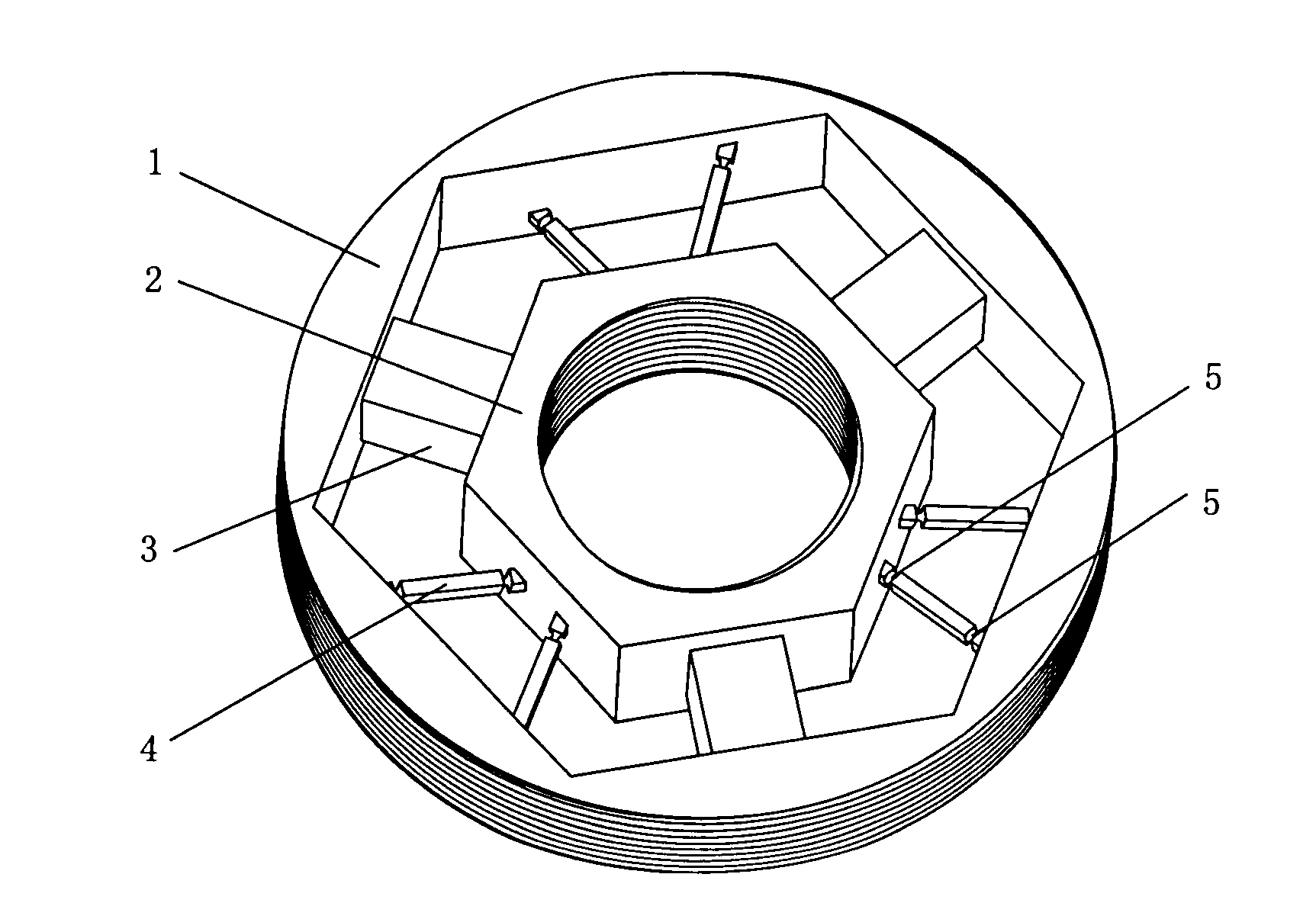

[0016] exist figure 1 In the schematic diagram of the structure of the parallel six-dimensional force sensor shown, the fixed ring 1 and the force measuring ring 2 are connected through three identical bearing branches 3, the fixed ring and the force measuring ring are coaxial, and the connecting surface is a hexagonal surface, The three bearing branches are evenly distributed on the three alternate facets; the inner surface of the force measuring ring is provided with threads, and the end surface of the fixed ring is provided with six through holes, which are connected with the outside through bolts. The six detection branches 4 are in groups of two, and are arranged in a near-singular configuration in which the axis and the cross-section of the sensor shaft form a small angle. The bearing branches are equally arranged on the other three facets. This structure is suitable for the measurement task that requires the sensor axial force and the two-dimensional torque measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com