Synchronizer-free gear shifting system for input shaft speed regulation for electric automobile

A technology for electric vehicles and input shafts, applied in transmissions, gear transmissions, components with teeth, etc., can solve the problems of reduced adaptability to working conditions, increased volume and mass, and the impact of maximum vehicle speed, so as to reduce the load And the effect of reducing power requirements and output torque requirements and improving adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

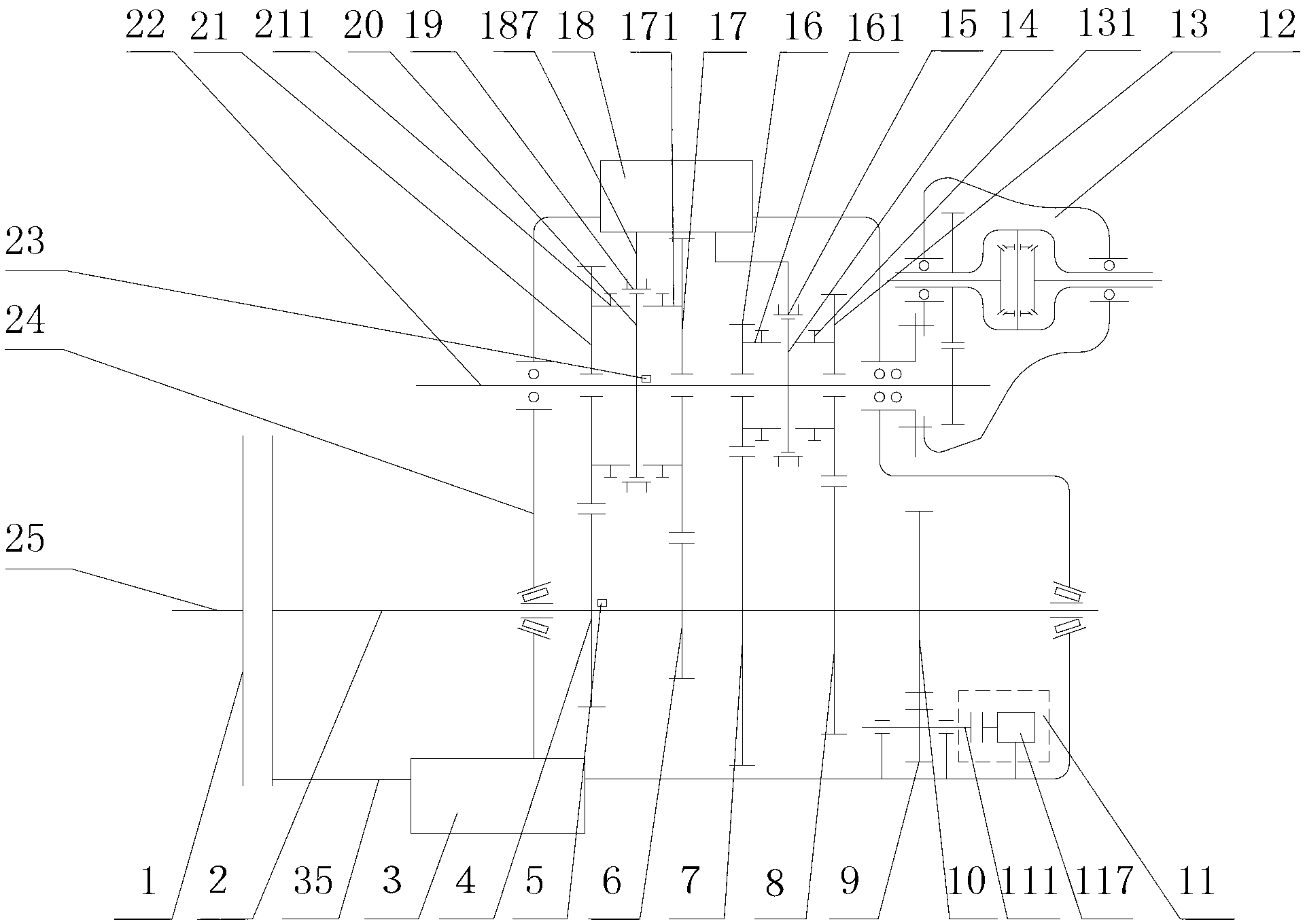

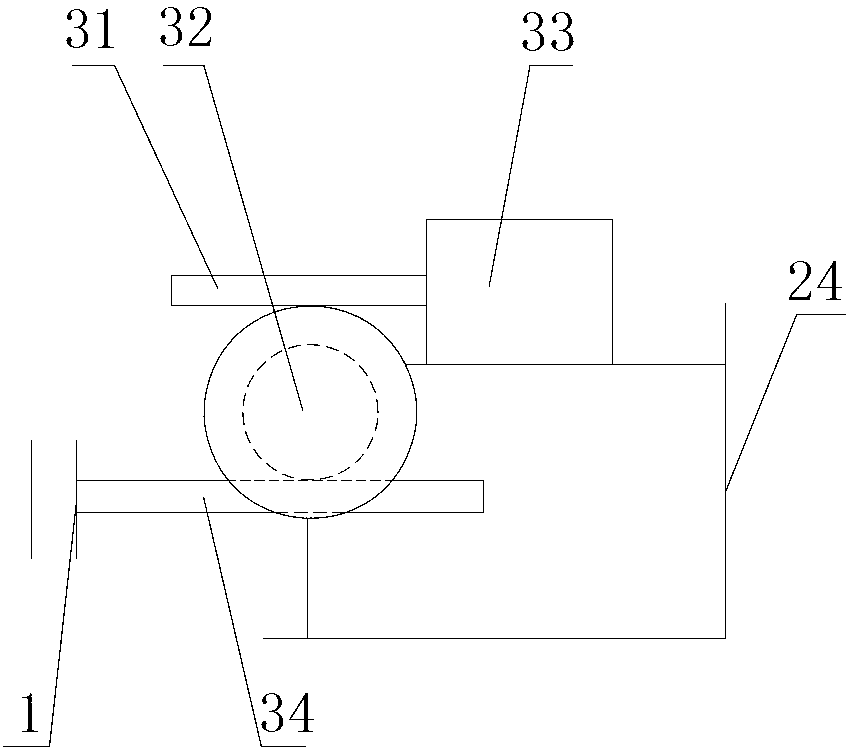

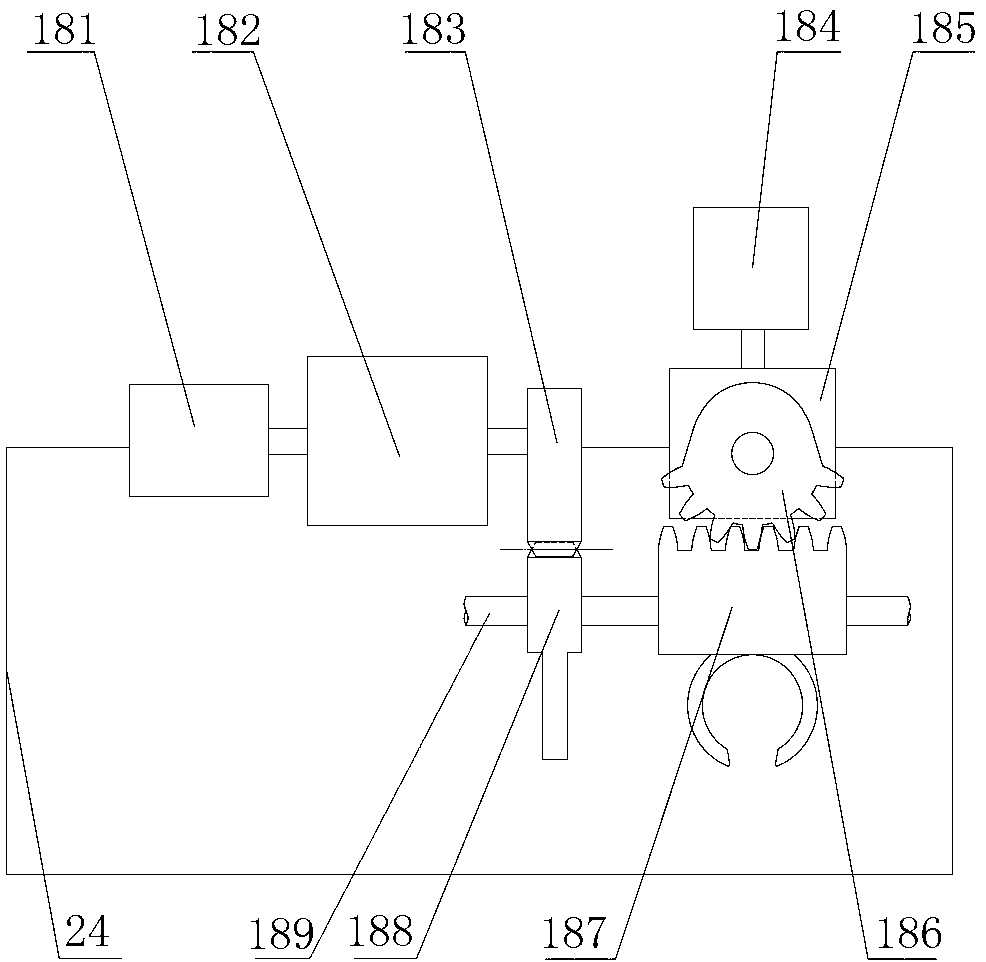

[0028] The present invention is used in the gear shifting system without synchronizer for the speed regulation of the input shaft of the electric vehicle, and its structure is as follows: figure 1 As shown, it includes: drive motor output shaft 25, clutch 1, input shaft 2, output shaft 22, clutch operating mechanism 3, shift actuator 18, transmission mechanism and speed regulating connection mechanism 11; described drive motor output shaft 25 It is connected to the input shaft 2 through the clutch 1.

[0029] The two ends of the input shaft 2 are supported on the gearbox body 24 through tapered roller bearings, and the input shaft 2 is provided with a second-speed driving gear 4, a first-speed driving gear 6, a fourth-speed driving gear 7, and a third-speed driving gear. 8 and transmission mechanism driven gear 10, wherein, the second gear driving gear 4, the first gear driving gear 6, the fourth gear driving gear 7, the third gear driving gear 8 are integrated with the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com