Adjustable center propeller bearing device

A technology for bearing devices and propellers, applied in the direction of bearing components, shafts and bearings, sliding contact bearings, etc., can solve the problems of reducing the service life of bearings, dry friction and crawling, self-excited vibration of bearings, etc., and achieve strong wear resistance and corrosion resistance , prolong the service life and improve the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

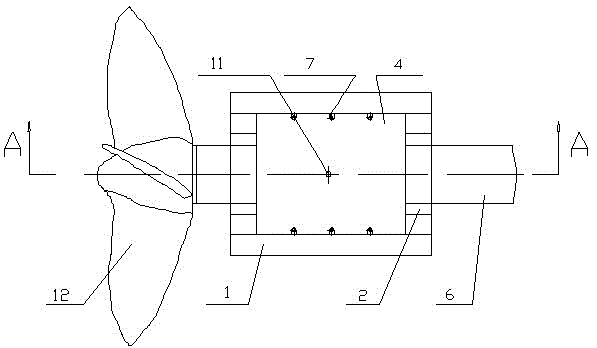

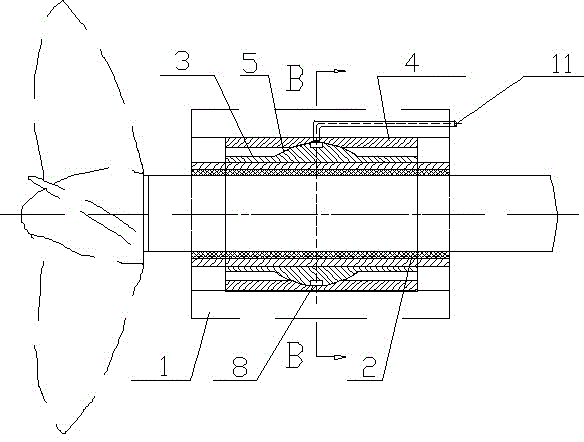

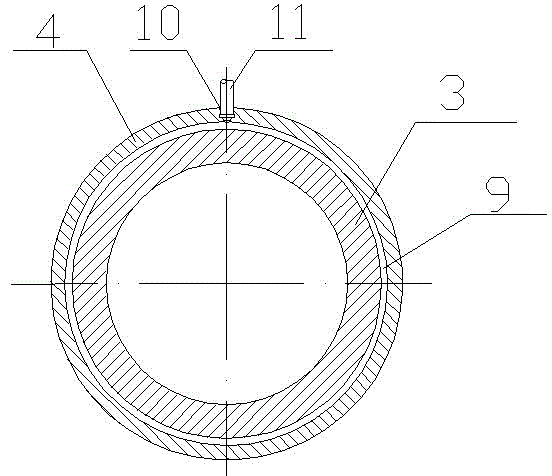

[0017] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] It includes a bearing seat 1 that is fixedly connected with the stern frame of the hull, and a self-aligning sleeve is installed on the inner cavity seat of the bearing seat. The outer sleeve 4 of the seat, the outer peripheral spherical surface of the inner sleeve is a convex spherical surface 5, and the ball seat of the outer sleeve is a concave ball seat. The diameter of the convex spherical surface of the inner sleeve is larger than the outer peripheral diameter of the inner sleeve, and the diameter of the convex spherical surface of the inner sleeve is smaller than the axial length of the inner sleeve. The inner sleeve is fitted in the inner hole of the outer sleeve, the diameter of the spherical surface of the concave ball seat of the outer sleeve is the same as the diameter of the convex spherical surface of the inner sleeve, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com