A quick-connect device suitable for heavy-duty rotary joints

A technology of quick connection and rotary joints, which is applied in the manufacture of tools and hand-held tools, etc., can solve the problems of fatigue cracking, cumbersome maintenance process, and short service life of the air shaft, so as to improve the fatigue strength of the spring and make the operation and maintenance simple , Improve the effect of system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

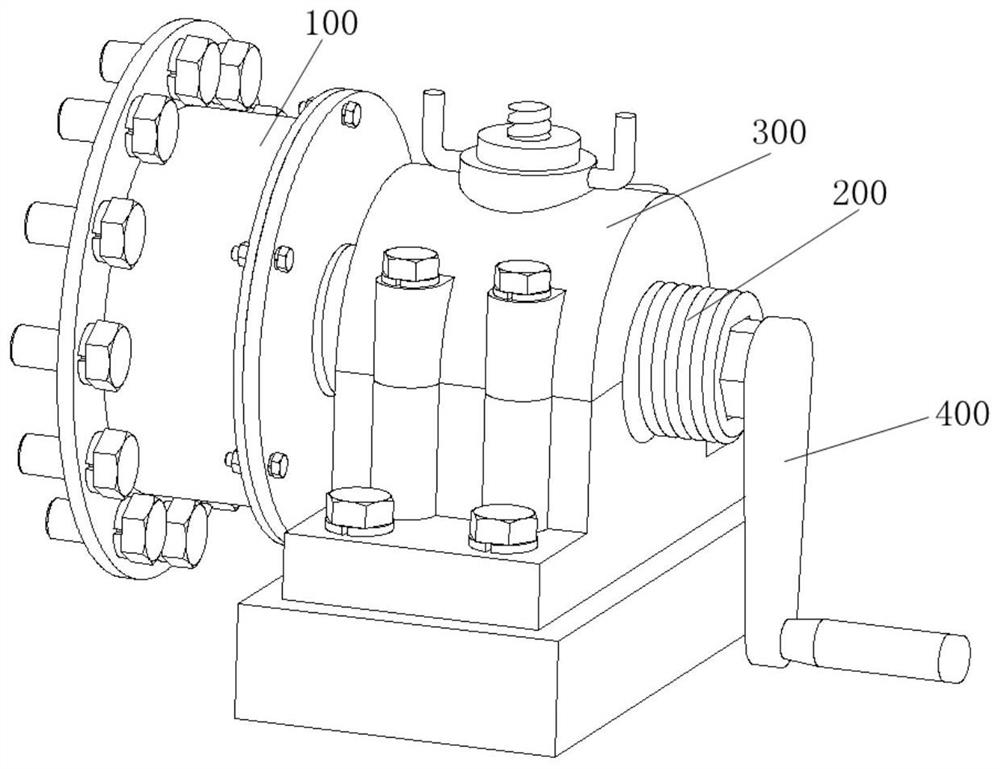

[0047] like Figure 1-16 , a quick connection device suitable for heavy-duty rotary joints of the present invention includes,

[0048] a main shaft 200, the main shaft 200 includes a conical end portion 210 and a cylindrical body portion 220, and the body portion 220 is provided with a first thread 2201;

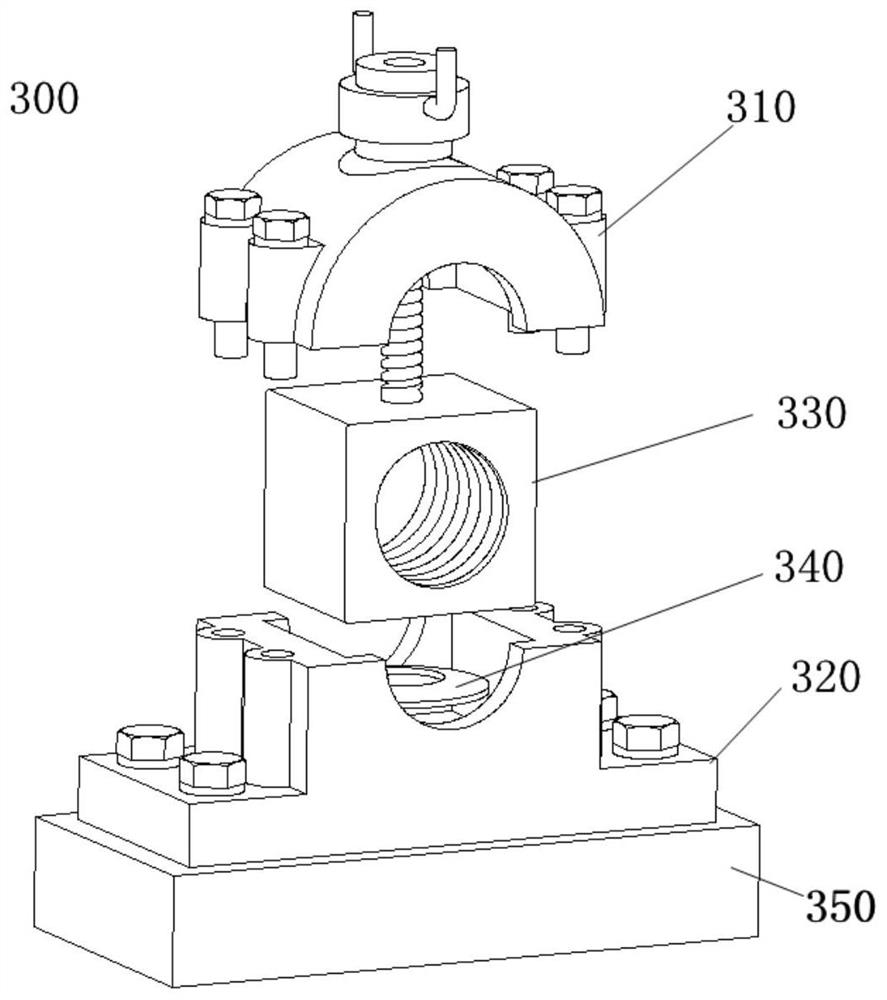

[0049]The spindle guide seat 300, the spindle guide seat 300 is provided with a second thread 3301, and the second thread 3301 is matched and connected with the first thread 2201 on the main shaft body portion 220;

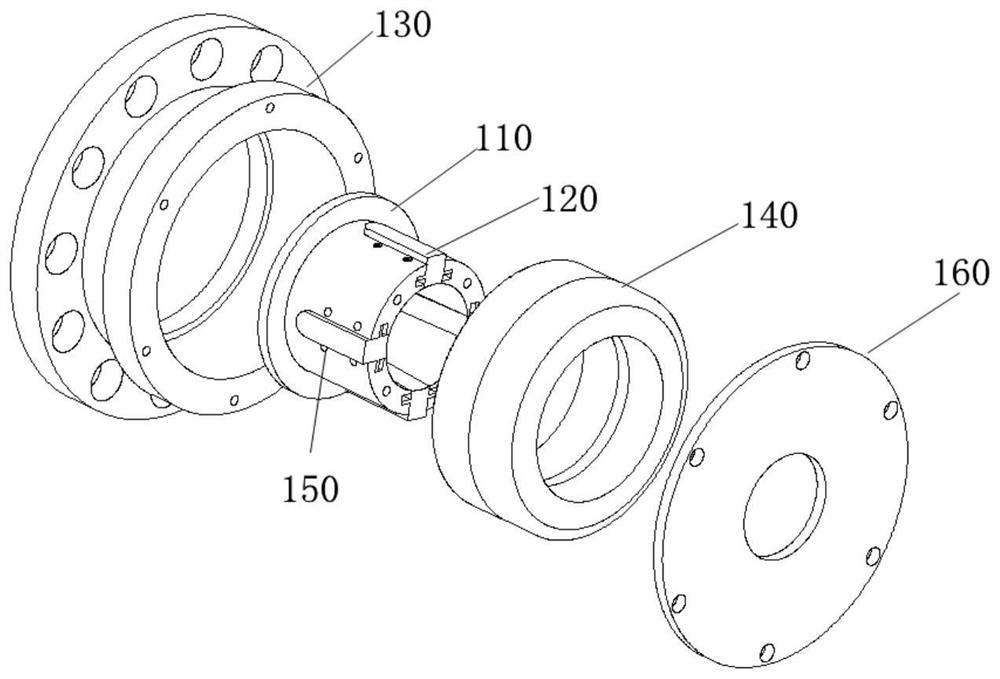

[0050] The expansion mechanism 100 includes:

[0051] The shaft barrel 110, the inner surface of the shaft barrel 110 is tapered, and can be matched with the end 210 of the main shaft 200; the barrel wall of the shaft barrel 110 is provided with a plurality of grooves 1101 penetrating the barrel wall, The size of the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com